P

PG

G-

-6

60

00

00

0

T

Th

hr

re

ea

ad

d

D

Di

ia

am

me

et

te

er

r

G

Ga

ag

ge

e

O

Op

pe

er

ra

at

ti

io

on

n

M

Ma

an

nu

ua

al

l

Introduction

The PG-6000 Series of the Thread Diameter Measurement Gages inspects the functional size of

internal threads ranging from 1 ½”-24”. The functional size of a thread is the size at which two parts will

screw together. To inspect functional size, the PG-6000 gages detect discrepancies in the cumulative

effects of thread element variations in flank angle, lead (including uniformity of helix) taper, and

roundness.

The PG-6000 gages use thread rolls that are precision ground in matched sets to ANSI specifications

to ensure maximum accuracy. The thread rolls seat in the thread form during inspection and reports

actual measurement readings on the gage’s indicator. Each set of thread rolls is designed to measure a

range of diameters for a specific thread form and pitch. The thread roll design allows them to make

rolling contact with the threaded part, causing minimal wear on thread rolls and eliminating damage to

parts.

Before inspecting parts, the PG-6000 gages must be preset to a nominal predetermined dimension. For

determining the gage’s setting dimensions, gauging tolerances, and specific type of thread roll for the

application, the Thread Disk for Windows program is available as an option. The PG-6000 gages can

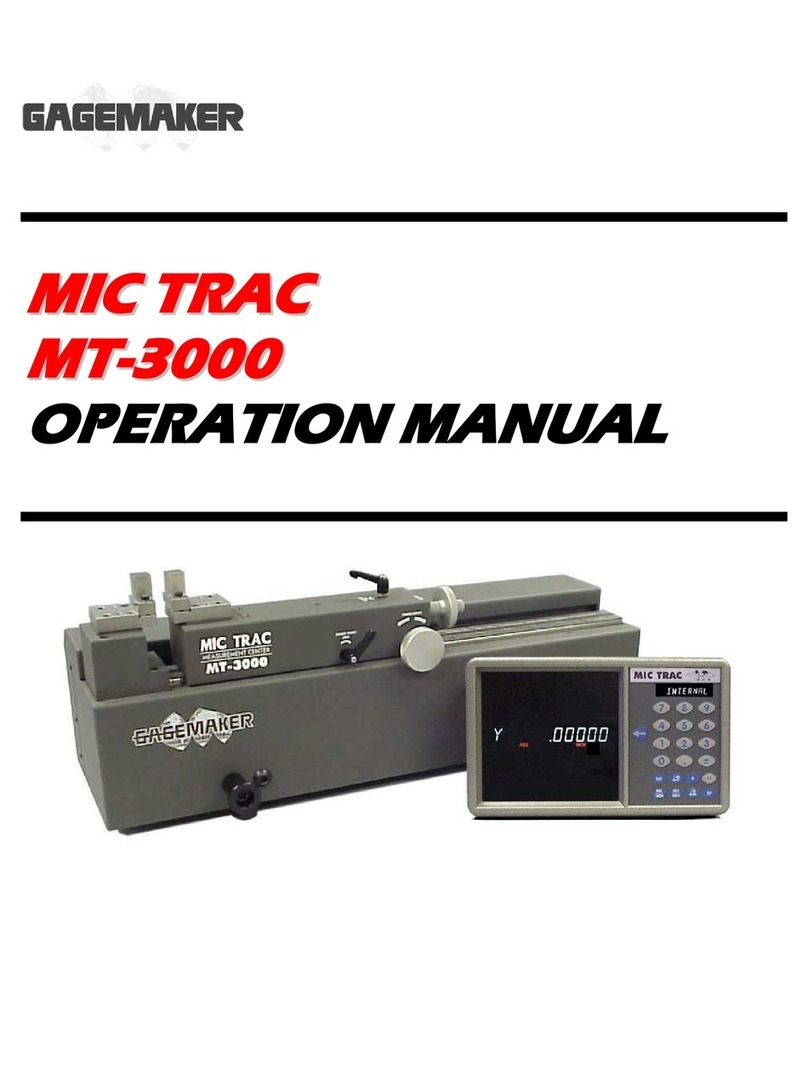

be preset using gage blocks or the MIC TRAC MT-3000 measurement center.

To inspect parts, the thread rolls are placed in the threads of the part and the gage is properly

positioned by sweeping to obtain the largest indicator reading. Taking measurements in several

different locations along the entire length of the thread will detect any variations in functional size. It is

also recommended that the gage be zeroed periodically during use to maintain accurate readings.

Technical Support

Phone: 713-472-7360

Hours: Monday – Friday 8AM – 5PM (CST)

Product Information and Updates

Visit our web site at: www.gagemaker.com