T

TF

F-

-D

DG

G

C

CA

AL

L-

-P

PA

AK

K

F

Fi

ix

xt

tu

ur

re

e

M

Ma

an

nu

ua

al

l

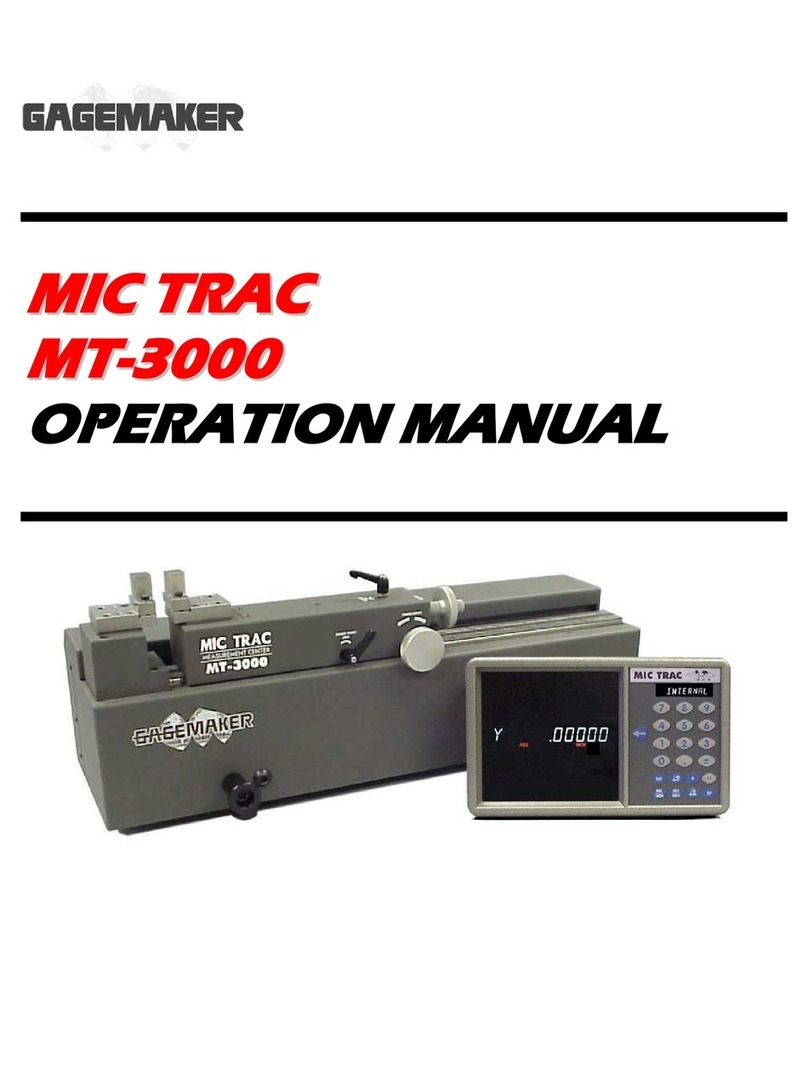

MIC TRAC MT-3000

3 2010 Gagemaker, LP

RCDMMT300010-10

Materials Needed:

•MIC TRAC MT-3000 base unit and CPU readout •5/32" hex wrench

•Depth micrometer •50 in/lb torque wrench

•

Depth gage fixture (TF-DG) and cap screws

•

•Flat face anvil (TF-1F Block) cap screws and washers •ZEP I.D. Red cleaner

•Depth gage support (TF-SS Block), for rods 6” and up

1. Inspect the depth micrometer visually as

follows:

•Check for damage and excessive wear.

•Check for burrs, nicks and wear on measuring

faces.

•Check for damage to measuring rods, rod

seating surfaces, and rod reading surfaces.

•Inspect for slack in the spindle thread by

pushing the assembly in and out. Adjust to

remove excess play.

•Check for proper function of the friction or

ratchet stop and spindle locking device.

•Check for smoothness of travel by rotating the

thimble throughout the range.

•Ensure all rods are straight.

2. Clean both of the receiver pads and the

mounting surfaces of the flat face anvil using

the cloth and ZEP I.D. Red cleaner.

3. Locate the left flat face anvil. Place the

shoulder side of the anvil against the left

receiver pad shoulder.