Mark Here

Procedures for Using the Pin Pitch Diameter Location Template and the

PD-8000-RSC External Pitch Diameter Gage

1. With the prole’s reference mark facing you and

the connector shoulder to your left, place the LPP

template on the threaded connector so the teeth

seat fully into the threads. The last length of the

template does not contact the shoulder.

2. With the teeth of the template seated fully in

the threads of the connector, slide the template

clockwise or away from you around the connector

until the left end of the template makes contact with

the pin shoulder. This is a rough clocking position.

3. Using a Sharpie® felt marker, place a mark on the

pin shoulder next to where the template contacts

the shoulder. Jog or rotate the machine spindle

until this mark is at the 12:00 o’clock position. This

makes it easier to locate and mark the measurement

position.

4. Place the template back onto the pin threads

just before the mark on the shoulder. Be sure that

the template threads are fully seated and parallel to

the pin centerline. Using a slight twisting motion,

slide the template in a clockwise direction or away

from you until the left edge of the template contacts

the shoulder. The twisting motion ensures that

the template is seated properly in the threads and

against the pin shoulder.

The pin pitch diameter location template or LPP is similar to a standard thread prole template with a

locator reference mark and a special shaped reference tooth. These reference indicators are used to

position and mark the location at which the pitch diameter of the connector will be measured. The LPP

location template works on standard pins as well as pins connectors with relief grooves. There are 11

different LPP templates based on specic TPI, TPF, and Thread forms.

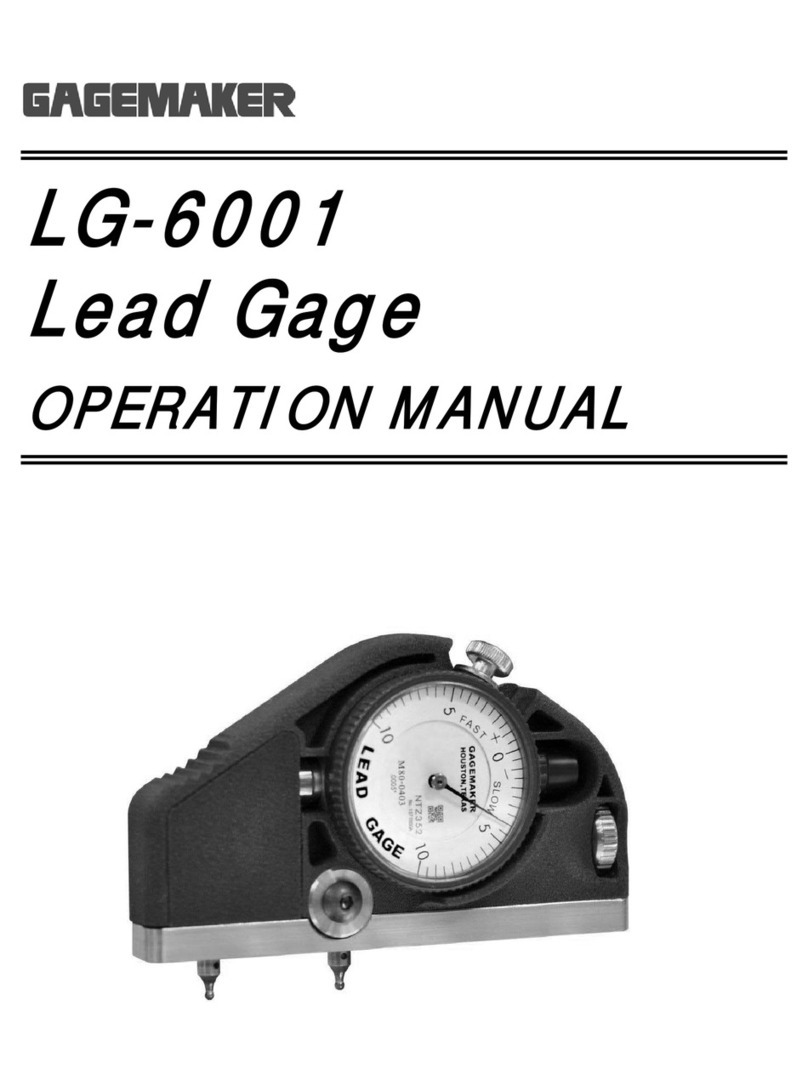

The PD-8000-RSC gage measures the deviation from nominal pitch diameter for the connector being

inspected. The gage uses xed and a moveable contact balls that are set into the thread’s helical path

at a predetermined location. The deviation is read directly from the indicator.

Applying the LPP to the Pin Connector

Mark now at 12 o’clock

© 2014 Gagemaker, LP