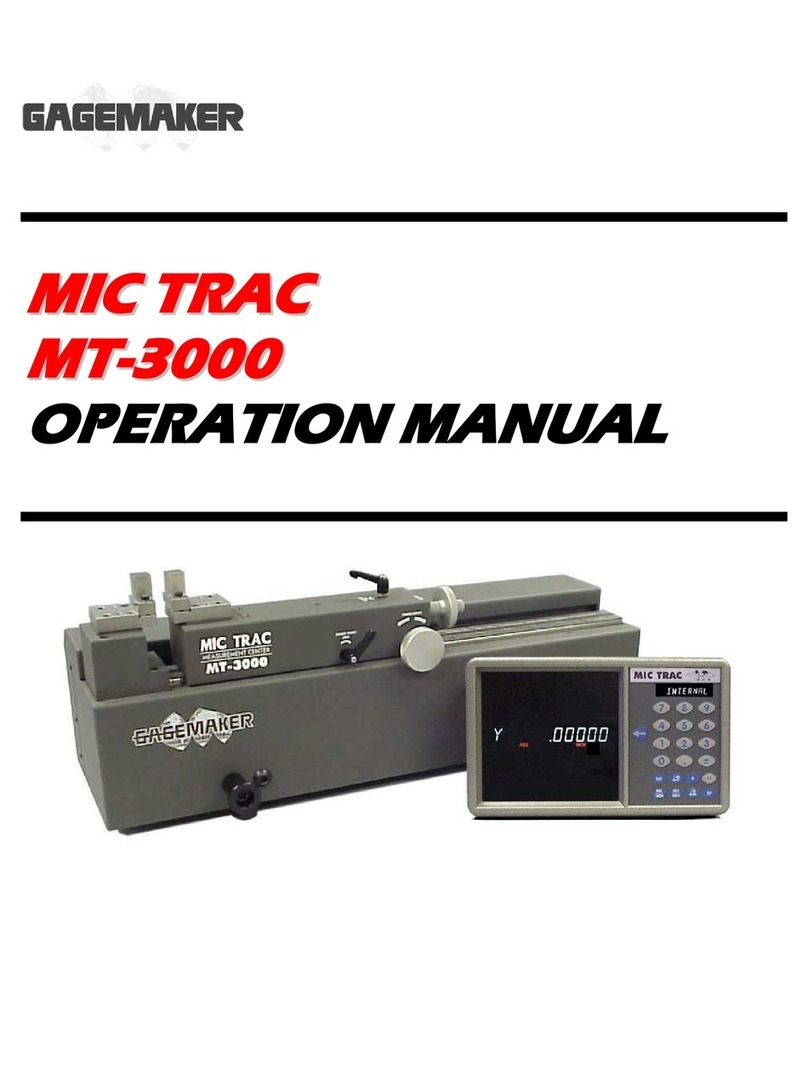

MIC TRAC Operation Manual Model MT-3000

4 Copyright © 2014 Gagemaker. All rights reserved

Introduction

What is the MIC TRAC?

The MIC TRAC is an electronic, adjustable calibration and measurement center that will improve your

ability to inspect parts, preset indicator style gages, and calibrate a variety of hand held inspection

gages. The MT-3000 measurement system includes the base unit. The base unit houses the optical

scale, which provides the MIC TRAC's precision measuring capability. The base unit may include an

optional Force-Lok™ feature that provides a constant measurement force, which improves repeatability

from operator to operator.

For gage calibration, the MIC TRAC measurement system can include the CAL-PAK, as an option. CAL-

PAK is an assortment of fixtures that attach to the base unit for holding gages securely during the

calibration process. Proper positioning of the gage improves the accuracy of the calibration and provides

more consistent results. Refer to the MIC TRAC MT-3000 Calibration Reference Cards and the Gage

Calibration Setup Poster for information about using the CAL-PAK fixtures.

Gagemaker’s Philosophy of Accuracy

Over a decade of research and development of calibration and measuring equipment has provided us

with many eye opening experiences into the realities of what accuracy means. Accuracy is subjective.

Accuracy is controlled by many physical elements, all of which have their own variables. Temperature

and humidity are just two factors that can affect accuracy.

It is critical to stabilize, monitor and adjust both temperature and humidity in order to maintain an

accurate environment. 68°F (20°C) and 50% humidity have been established by NIST as the

temperature at which measurements should be taken. Measurement or calibration in any other

environment should be evaluated prior to certification.

All equipment manufactured by Gagemaker, Inc. is accurate when operated according to our instructions

and under suitable environmental conditions. In many cases, to improve accuracy, you may need to

improve environmental conditions.

Technical Support

Phone: 713-472-7360

Hours: Monday – Friday 8AM – 5PM (CST)

Product Information and Updates

Visit our web site at: www.gagemaker.com