6

1.2.7.3 When:

The time the irrigation starts, date, number of cycles etc.

• In addition, the irrigation program contains informative data and definitions

(see following sections).

•

See more information about the irrigation program in the operating section.

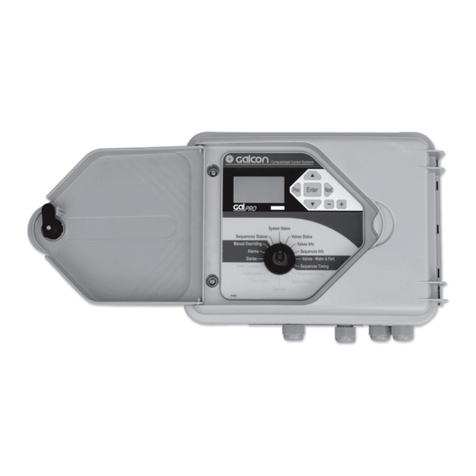

1.3 Operating via the computer:

The computer program is a graphic program and once defined, it is simple to operate

(in spite of the system sometimes being very complex) and provides good orientation

even to operators that are not totally familiar with hydraulic systems. Whilst operating the

computer the user is provided with a map or diagram of the field showing each object in

accordance with its geographical position. The operator can easily see both which events

are taking place and where they are taking place. By clicking on the object the operator

can see the object’s properties (set up, information, accumulations etc.) In addition, when

one object is incorporated in another object, clicking on the incorporated object number

leads to its properties being displayed and they can even be altered. For example: Clicking

on the valve number of a valve that is incorporated in the irrigation program displays the

valve’s properties. It is important to know that the memory and operating data (including

definitions) are only stored in the controller (not on the P.C). When a new screen opens,

the computer program requests the relevant data from the controller in order to create the

screen. A key appears on all screens that allow programming (data changes).

Click on the key in order to edit data.

This action changes the screen into editing mode whereby it is possible to move

between the cells and alter the required data. At the end of editing click on the

key again. This action causes the screen data to be sent to the controller.

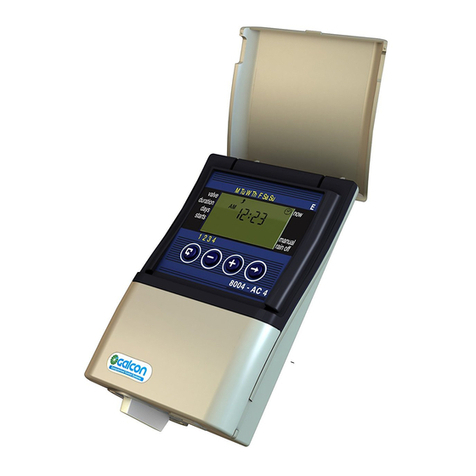

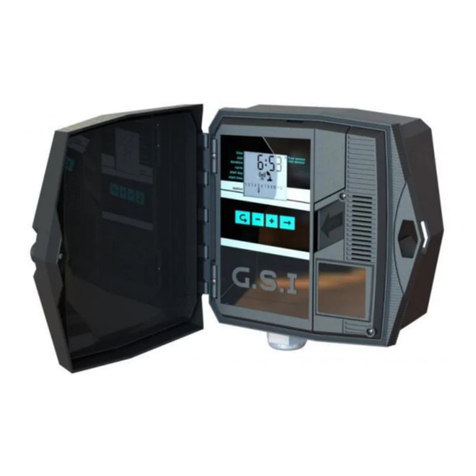

1.4 Operating Via the Controller:

The data in the controller is organized in tables. Each table consists of rows and columns.

The rows represent the various objects and the columns represent the different fields of

the object’s properties. For example in the irrigation program operating table, the rows are

irrigation programs i.e. row number 1 belongs to program number 1, row number 2 belongs

to program number 2 and so forth. The same table’s columns contain the respective

program’s properties. For example: amount of water, start time, operating days etc. The

controller is organized in menu form allowing access to the tables. Each menu is in fact a

list of objects that can in turn be divided into sub menus or contain tables. Moving between

the menus is by the use of the up and down arrows and moving inside the tables is by

the use of the up, down, right and left arrows. To go down a level click <enter>, in order

to go up a level click <exit>. On narrow screened controllers each screen is a single cell

in the table or one part of the menu. On the wide screened controllers several figures are

displayed: an entire menu or several fields of an object (described as a table row in the

data organization section). Tables can also be accessed by entering the table number

(shortcut). The table number is shown in the flow chart and in the menu details appearing

at the end of this manual.

1. Preface