Page 2 © GBC Films Group October 2000

Arctic Titan 165 Operation and Maintenance Manual

Important Safety Instructions

YOURSAFETYASWELLASTHESAFETYOFOTHERSISIMPORTANTTOGBC. INTHISINSTRUCTION

MANUALAND ONTHE PRODUCT,YOU WILLFIND IMPORTANTSAFETY MESSAGES REGARDING

THE PRODUCT. READ THESE MESSAGES CAREFULLY. READ ALL OF THE INSTRUCTIONS AND

SAVETHESE INSTRUCTIONS FORLATERUSE.

THESAFETY ALERT SYMBOLPRECEDES EACHSAFETY MESSAGEIN THIS

INSTRUCTIONMANUAL. THESYMBOLINDICATESAPOTENTIALPERSONALSAFETY

HAZARDTOYOU OR OTHERS,AS WELL AS PRODUCTOR PROPERTY DAMAGE.

THE FOLLOWING WARNINGS ARE FOUND UPON THE ARCTIC TITAN 165:

THISSAFETY MESSAGE MEANSTHATYOU COULDBE

SERIOUSLYHURTOR KILLEDIF YOUOPEN THEPRODUCT AND

EXPOSEYOURSELF TOHAZARDOUSVOLTAGE.

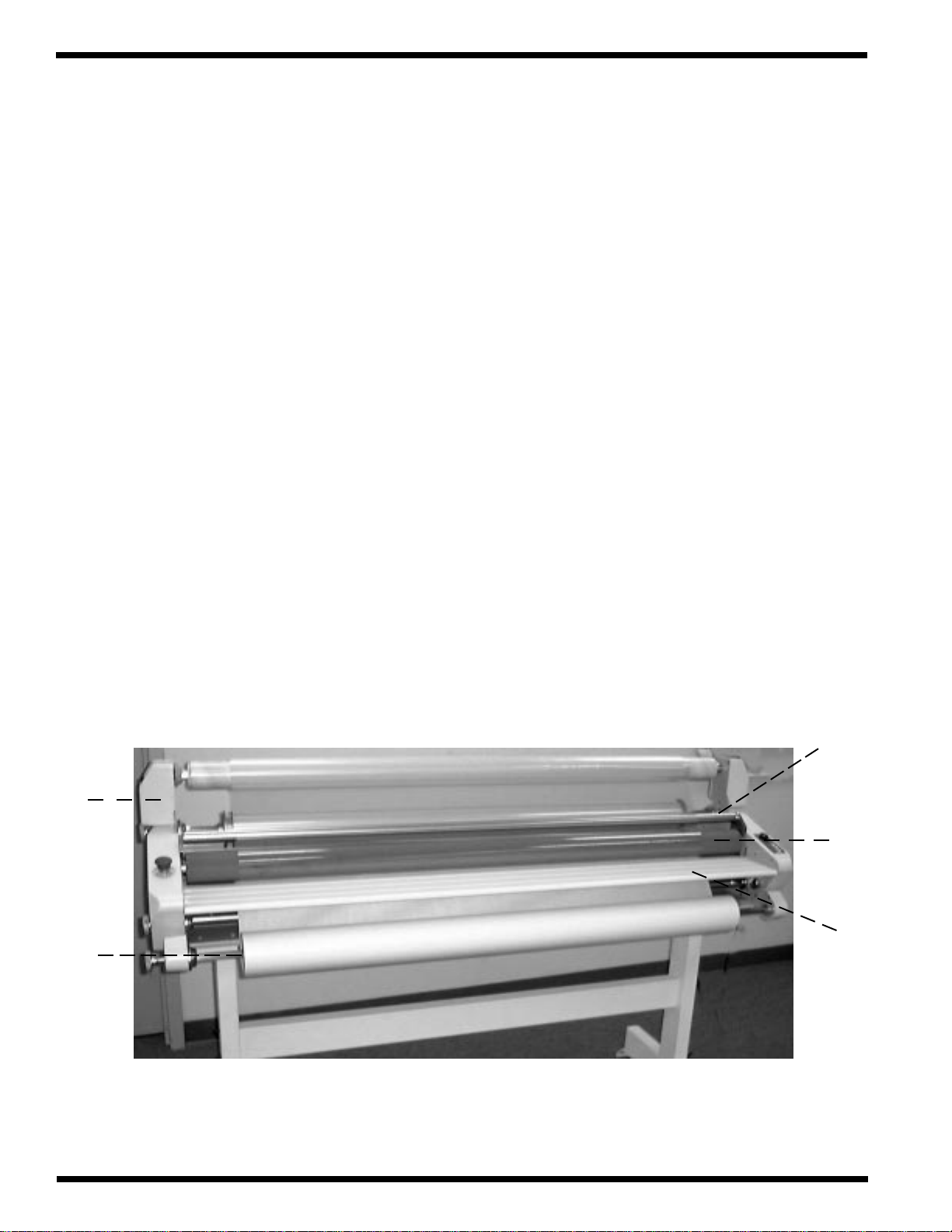

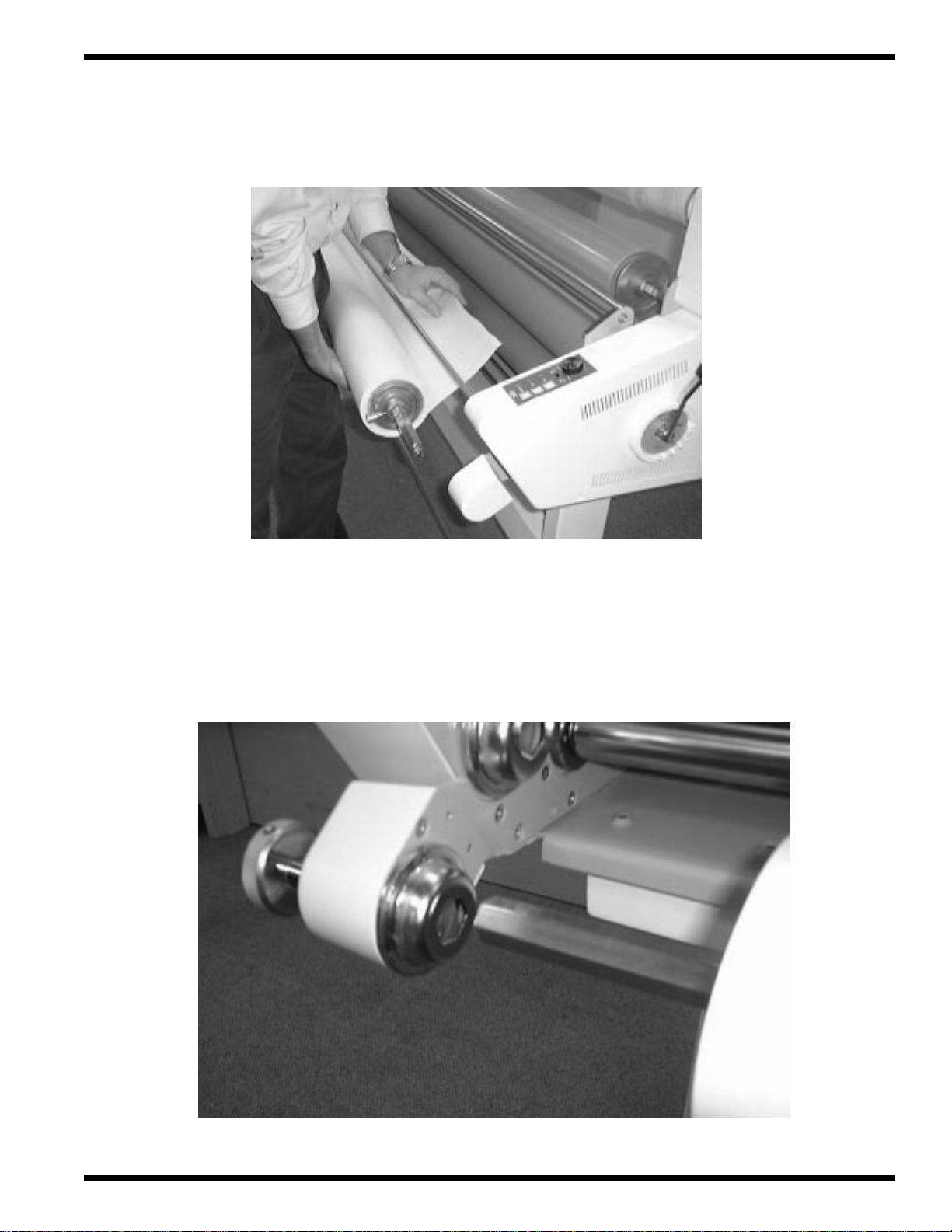

THISSAFETYMESSAGE MEANSTHATHANDS COULDBE

TRAPPEDAND CRUSHED INTHE ROLLERS. CLOTHING,

JEWELRY AND LONGHAIR COULD BECAUGHT IN THE

ROLLERSAND PULL YOUINTO THEM.

THISSAFETY MESSAGE MEANSTHAT YOUCOULD CUT

YOURSELFIF YOU ARE NOTCAREFUL.

WARNINGDO NOT ATTEMPTTOSERVICE ORREPAIRTHE ARCTIC TITAN

LAMINATOR.

WARNINGDONOT CONNECTTHE ARCTICTITAN LAMINATORTOAN ELECTRICAL

SUPPLYORATTEMPTTOOPERATETHELAMINATORUNTILYOUHAVECOMPLETELY

READTHESE INSTRUCTIONS. MAINTAIN THESEINSTRUCTIONSIN ACONVENIENT

LOCATION FOR FUTUREREFERENCE.

WARNINGTOGUARD AGAINSTINJURY, THE FOLLOWING SAFETYPRECAUTIONS

MUSTBE OBSERVEDIN THE INSTALLATION AND USEOF THE LAMINATOR.

MUCHO

CUIDADO

!

Riesgo de choque

electrico

No abra

Adentro, no hay

piezas reparables

para el usuario.

Mantenimiento

solamente para

personal calificado

ATTENTION

!

Risque de secousse

electrique.

Ne pas ouvrir.

Pas de pieces

reparables par

l'utilisateur.

Entretien par

personnel qualifie.

WARNING

!

Electrical shock

hazard.

Do not open.

No user serviceable

parts inside.

Refer servicing to

qualified service

personnel.

CUIDADO

!ATTENTION

!CAUTION

!

RODILLOS

CALIENTES.

PUNTO DE

PINCHAMIENTO.

Mantener manos y

ropa a distancia.

ROULEAUX

CHAUDS.

POINT DE

PINCEMENT.

Tenir mains et

vetements a l'ecant.

PINCH POINT.

Keep hands and

clothing away.

CUIDADO

!ATTENTION

!CAUTION

!

NAVAJA FILOSA.

Mantener manos y

dedos a distancia.

LAME COUPANTE.

Tenir mains et

doigts a l'ecant.

SHARP BLADE.

Keep hands and

clothing away.