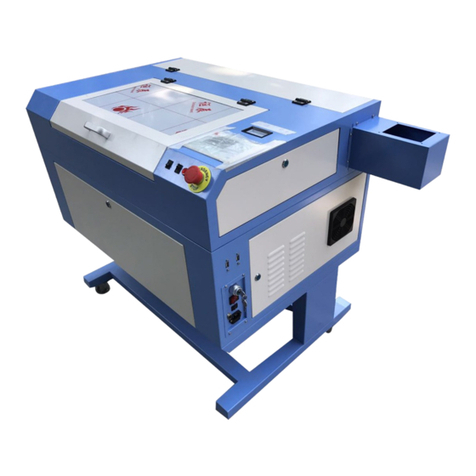

E200 User Manual I

TABLE OF CONTENTS

Chapter 1 Safety..............................................................................................................................................5

1.1 Principles of a CO2 Laser................................................................................................................6

1.2 Safety Ratings....................................................................................................................................6

1.3 The Safety Interlock System............................................................................................................6

1.4 Safety Labels......................................................................................................................................6

1.5 Safety Measures..............................................................................................................................10

1.6 Operating Environment...................................................................................................................11

1.7 Noise Test .........................................................................................................................................11

Chapter 2 Unpacking....................................................................................................................................12

2.1Unloading and Unpacking...............................................................................................................13

Chapter 3 Mechanical Overview.................................................................................................................16

3.1 Front View.........................................................................................................................................17

3.2 Top View............................................................................................................................................17

3.3

Right

(Profile)

V

iew

.......................................................................................................................18

3.4

Left

(Profile)

V

iew

..........................................................................................................................18

3.5 Rear View

........................................................................................................................................19

3.6 Water Chiller Front View

.............................................................................................................20

3.7 Water Chiller Right View

.............................................................................................................21

3.8 Water Chiller Left View

................................................................................................................21

3.9 Water Chiller Rear View

..............................................................................................................21

Chapter 4 Machine Setup ............................................................................................................................22

4.1Water Chiller Setup..........................................................................................................................23

4.2E200 Machine Setup .......................................................................................................................26

Chapter 5 Software Setup ...........................................................................................................................28

5.1Recommended Computer Configuration......................................................................................29

5.2E200 Software - SmartJOB Installation ........................................................................................29

5.3E200 Driver Installation ...................................................................................................................32

Chapter 6 Connection Setup ........................................................................................................................33

6.1 Machine Connection Setup...........................................................................................................34

6.2Computer Assigns the Connection Method .................................................................................36

6.3 Connection Troubleshooting..........................................................................................................43

Chapter 7 Operating the GCC LaserPro E200.........................................................................................45

7.1 How to use focus tool......................................................................................................................46