Vision Express S5 User Manual6

© 2018 Vision Engraving & Routing Systems

1.1 Disclaimer and Warranty Information

Limits of Liability / Disclaimer of Warranty

The information contained within this manual has been carefully checked and is believed to be accurate,

however, Vision makes no representations or warranties for this manual, and assumes no responsibility

for inaccuracies, errors, or omissions that may be contained within this manual. In no event shall Vision

be liable for any loss of profit including (but not limited to) direct, indirect, special, incidental,

consequential, or other damages resulting from any defect or omission in this manual, even if previously

advised of the possibility of such damages.

In the interest of continued product development, Vision reserves the right to make improvements to this

manual and the products it describes at any time, without notice or obligation.

Limited Warranty:

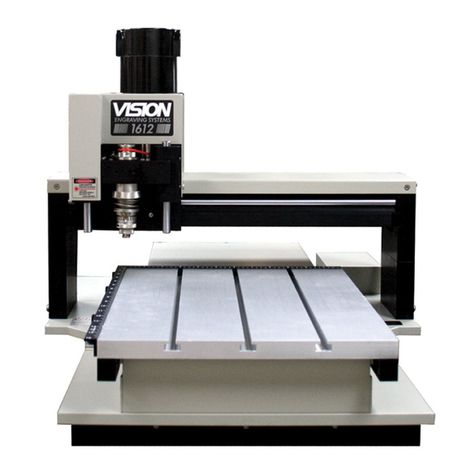

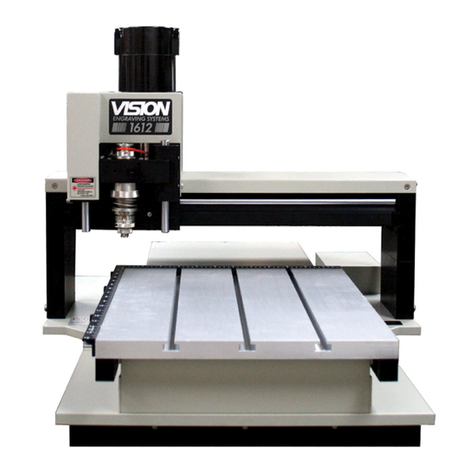

Vision Computerized Engraving and Routing Systems (and Retrofit Tables)

Vision Computerized Engraving and Routing Systems (Vision) warrants that for a period of one (1) year

from the date of shipment to the original purchaser of an Express, VE810,or VR48 or a period of two (2)

years from the date of shipment to the original purchaser for a Phoenix1212, 1612Pro, 1624Pro, 2424,

2448, 2525Router, 2550Router, MaxPro, The MAX, or Table Retrofit (the System), that the System will

be free from defects in material and workmanship under normal use and service. Upon written

notification, we will transfer the remaining warranty to a new customer. This warranty shall cover all

elements except for items covered by separate manufacturer’s warranties and consumable items.

“Consumable” items include, but shall not be limited to, belts, brushes, lubricants, and cutters furnished

with the System, for which no warranty is provided.

In the event a defect is discovered during the warranty period, within thirty days of discovery, but no later

than the last day of the warranty period as described above, the user shall contact Vision for instructions

regarding disposition of the problem. Vision shall, at its option, either (1) repair the affected product with

new or refurbished parts, or (2) provide a replacement. Any incidental costs, including the cost of

shipment from the user’s location to the point of repair and return, and any installation performed by the

user, shall be at the expense of the user.

This warranty covers normal use only and shall be void in the event that the System is altered or modified

without authorization by Vision, or is subject to abuse, neglect, or other misuse by the user.

The warranties for Third-Party Hardware and Third-Party Software shall run directly from the

manufacturers of such hardware and software to the user. Vision makes no warranties, expressed or

implied, with regard to Third-Party Hardware or Third-Party Software.

Vision does not warrant any product, component, or part not manufactured by Vision that was not

supplied by Vision. (Third-party items, including but not limited to software, are subject to their own

manufacturer’s warranties.) Vision does not warrant defects caused by a failure to provide a suitable

environment for the system, by unauthorized attachments, by modifications or repairs other than by

Vision, by use of the System for other than its original intention, or by other misuse or abuse of the

System.

Extended Warranty

An Extended Warranty may be purchased which extends the terms of the original equipment Warranty in

1 year increments for a period of up to 30 days after the original equipment Warranty expires. An

Extended Warranty may also be purchased for a period of up to 30 days after an existing Extended

Warranty expires. Extended Warranties cannot be purchased on any equipment that is 7 or more years

old, or if there is a Lapse of Warranty. Age of equipment is determined from the date of shipment to the

original buyer.