232001410G(10)

1

Table of Contents

Chapter 1.............................................................................................................3

Safety..................................................................................................................3

1.1 Principles of a Fiber Laser.....................................................................4

1.2 Safety Ratings .......................................................................................4

1.3 The Safety Interlock System .................................................................4

1.4 Safety Labels.........................................................................................4

1.5 Safety Measures....................................................................................9

1.6 Operating Environment.......................................................................10

1.7 EC-Declaration of Conformity..............................................................11

Chapter 2...........................................................................................................12

Unpacking& Contents......................................................................................12

2.1 Unloading/Unpacking / Repacking........................................................13

2.2 Contents and Accessories Checklist...................................................23

Chapter 3...........................................................................................................24

Mechanical Overview.........................................................................................24

3.1 Front View............................................................................................25

3.2 Top View ..............................................................................................25

3.3 Right (Profile) View..............................................................................26

3.4 Left (Profile) View................................................................................26

3.5 Rear View ............................................................................................27

Chapter 4...........................................................................................................28

Setup and Installation.........................................................................................28

4.1 Machine Setup.....................................................................................29

4.1.1 Powering Up the Machine ..........................................................29

4.1.2 Connecting the Computer...........................................................29

4.1.2.1 Networking Connectivity Setup .............................................30

4.1.2.1 Ethernet Connectivity Setup..................................................33

4.2 Graphics Software Setup.....................................................................38

4.2.1 Recommended Computer Configuration....................................38

4.2.2 Installation of the LaserPro Print Driver......................................38

4.2.3 Using Parallels Desktops for MAC OS .......................................40

4.2.4 Using AutoCAD Inventor with GCC LaserPro machine..............45

4.2.8 Using eCut Plug-in with GCC LaserPro machine.......................47

Chapter 5...........................................................................................................48

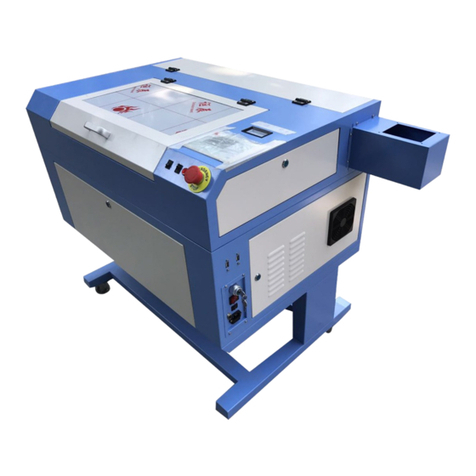

Operating the LaserPro S290LS........................................................................48

5.1 Using the Hardware.............................................................................49

5.1.1 Laser Key Switch ......................................................................49

5.1.2 Adjusting the LCD Display Screen’s Contrast Setting.................49

5.1.3 Graphic Control Panel Overview................................................50

5.1.4 Graphic Control Panel Navigation Chart.....................................52

5.1.5 Graphic Control Panel Function Pages ......................................53

5.2 The LaserPro S290LS Print Driver......................................................81

5.2.1 Page Setup and Orientation.......................................................81

5.2.2 Color Management.....................................................................83

5.2.3 Using the LaserPro S290LS Print Driver....................................84

5.2.3.1 LaserPro S290LS Print Driver >> Options Page ..............85

5.2.3.2 S290LS Print Driver >> Pen Page...................................91

5.2.3.3 LaserPro S290LS Print Driver >> Advanced Page...........96