Page 4

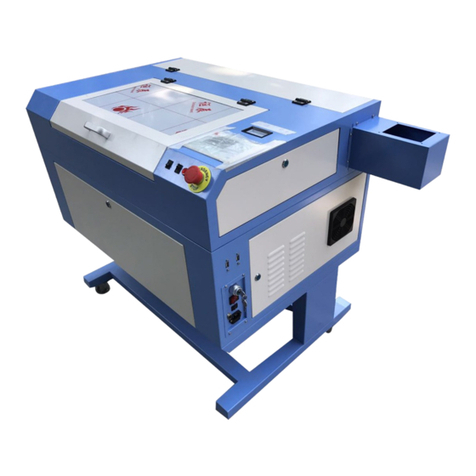

Your WF-Education Group Laser and tube are warrantied against manufacturing defects for a period of 2 years from the date of purchase, this warranty excludes any consumables

items. Subject to the terms and conditions listed below, the warranty will provide for the on-site repair of the laser, or any component thereof, which is identified as faulty or

below standard, or is a result of inferior workmanship or materials.

- The warranty shall only apply to defects that occur within the 2 year period (12 months on the laser tube).

- Any repair must be carried out by an authorised service technician - any unauthorised work will invalidate the warranty.

- The warranty does not cover any faults or defects caused by accident, misuse, fair wear & tear, neglect, tampering with the equipment, or any

attempt at adjustment or repair other than through WF-Education Group. Non-warrantied repair visits are chargeable at the current

technicians rate.

- If you experience difficulty using the product, please firstly refer to this manual, if the information you require is not avaliable in the manual then

please visit the laser FAQ section on our website www.technologysupplies.co.uk If you are still unsuccessful then phone the Technology Supplies

Technical Line for support (please see bottom of this page).

- In the unlikey event of a defect occurring, please phone WF-Education technical Line to arrange a technician’s visit.

- Becasue of the nature of the product, if your laser needs repair after the warranty period, the repair must only be carried out by an authorised

service technician. Further damage to the machine and also risks to health may occur when working with laser cutters if correct procedures and

parts are not used.

- In the event of a defect occurring, please first contact the WF-Education technical Line who will attempt to resolve or determine the issue prior to

arranging for a laser engineer to attend.

These are items that either have a limited life or their life is directly affected by their use, maintenance and care taken with them. For example the filters in the extraction units

have a limited number of hours before becoming clogged and are therefore not covered by any warranty.

The following items are classed as consumables and are not covered by the warranty.

* Fume Extraction Filters * Grid bed * Gas Struts for Lid

* Lens & Mirrors (their life is dependant on cleaning and maintenance) * Autofocus Probe and connecting components

WF-Education includes unlimited support throughout the life of the laser cutter.

1) The latest drivers, and FAQs, along with updated manuals are published via our website www.technologysupplies.co.uk

2) Telephone Support via our Technical Line on 01743 812200, option 2, one of our dedicated technical team members will be happy to help with your enquiry.

The Conditions of this Warranty are;

Within the 2 Year Warranty Period;

Outside the Warranty Period;

Consumables;

Total Product Technical Support;

Warranty Information