Contents

Ⅰ. Introduction........................................................................................................ - 2 -

Ⅱ. Test Function..................................................................................................... - 2 -

Ⅲ. Technical Parameter........................................................................................ - 2 -

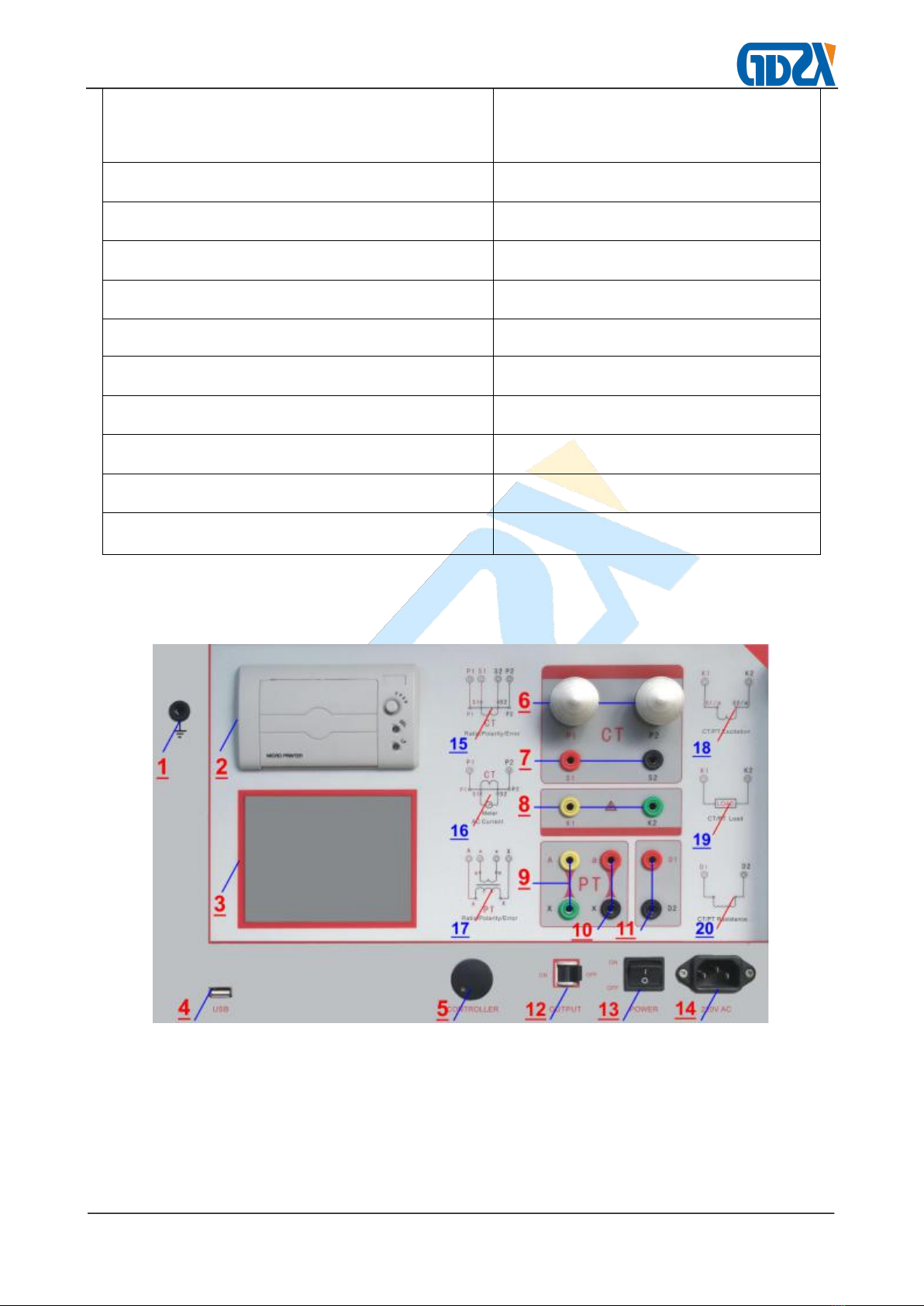

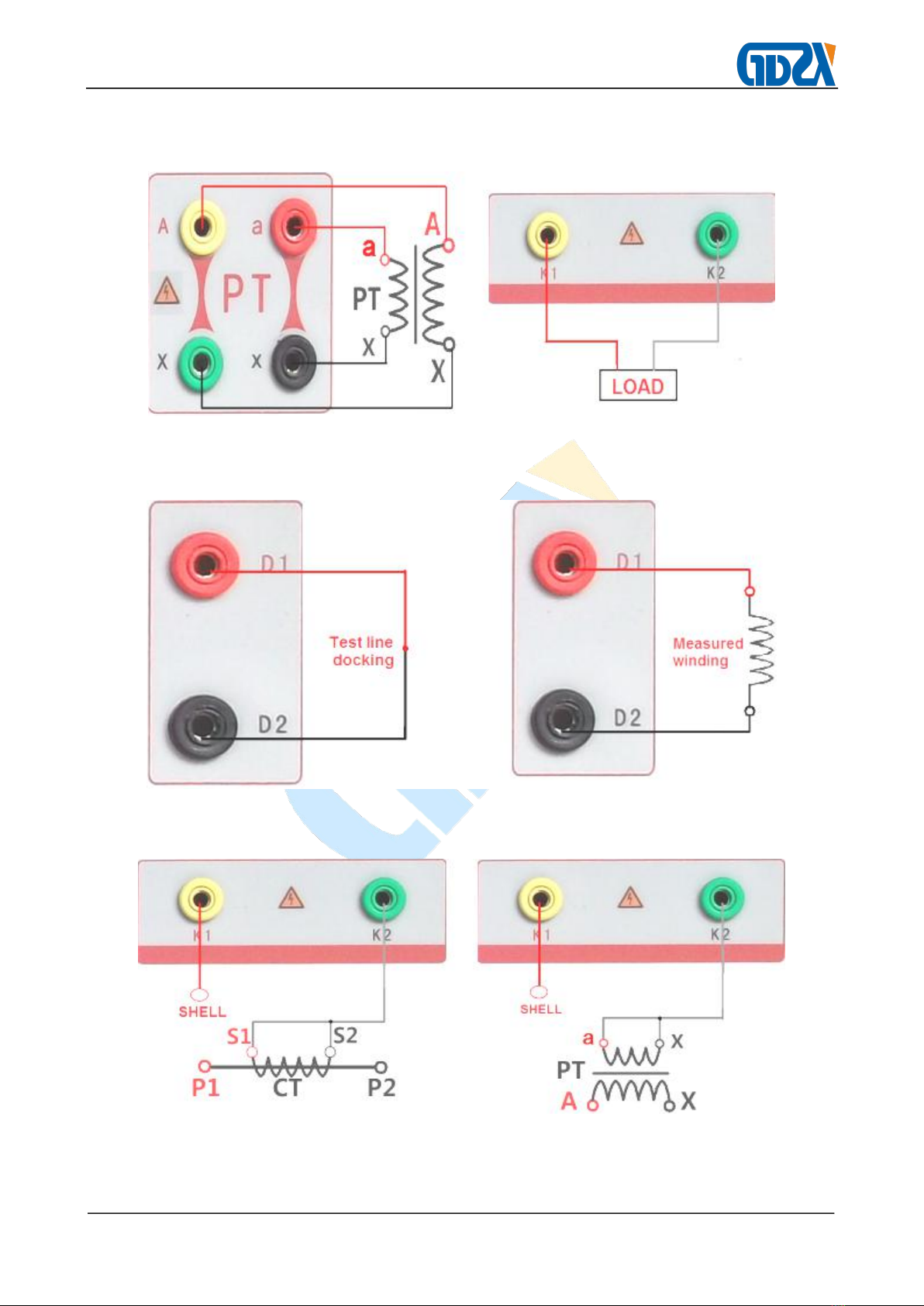

Ⅳ. Panel Introduction............................................................................................. - 3 -

Ⅴ. Operation Method............................................................................................. - 6 -

1. Controller...........................................................................................................- 6 -

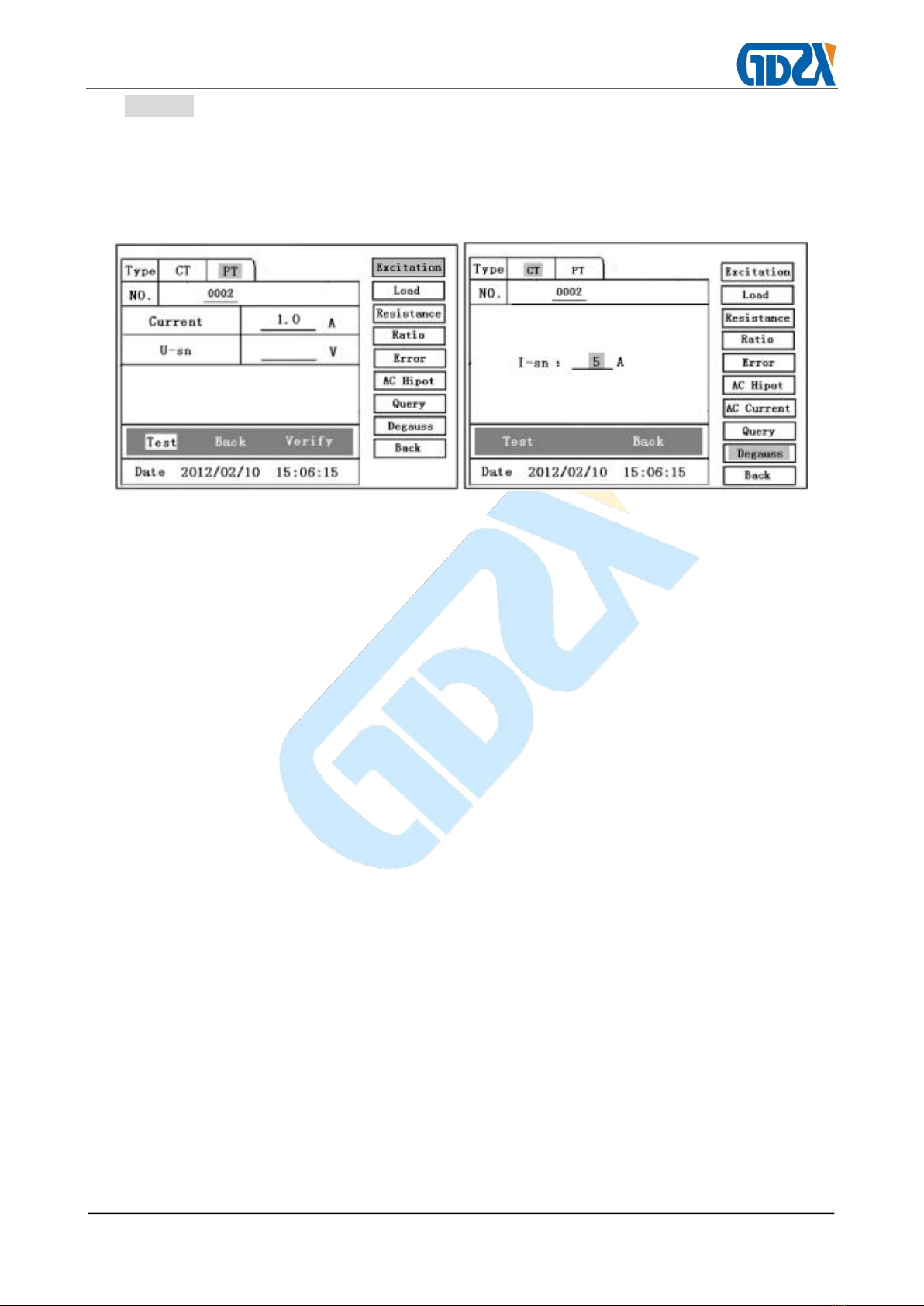

2. Main Menu........................................................................................................ - 6 -

3. Excitation...........................................................................................................- 6 -

4. Degauss Test................................................................................................... - 9 -

5. AC Current:Current Output.......................................................................... - 10 -

6. Ratio:Ratio and Polarity Test....................................................................- 10 -

7. Error Test........................................................................................................ - 12 -

8. Load Test........................................................................................................ - 13 -

9. Resistance Test............................................................................................. - 14 -

10. AC Hipot (Voltage Withstand Test of Alternating Current).................. - 15 -

11. Index (Query)............................................................................................... - 16 -

12. PC Software................................................................................................. - 17 -

Ⅵ. Precautions...................................................................................................... - 18 -

Ⅶ. Packing List......................................................................................................- 18 -

Appendix.................................................................................................................- 20 -