Ⅰ、product description

Once the power system commonly used conventional QJ44 type arm DC bridge for measuring

the contact resistance, and such bridge only test current at mA level, it is difficult to find

transformer coil conductor cross-sectional area reduced defects. When measuring the high voltage

switch contact resistance of the conductive circuit, due to the impact of oil film between the contact

and the oxide layer, the measured resistance value is too much times larger that can not reflect the

real value of the contact resistance.

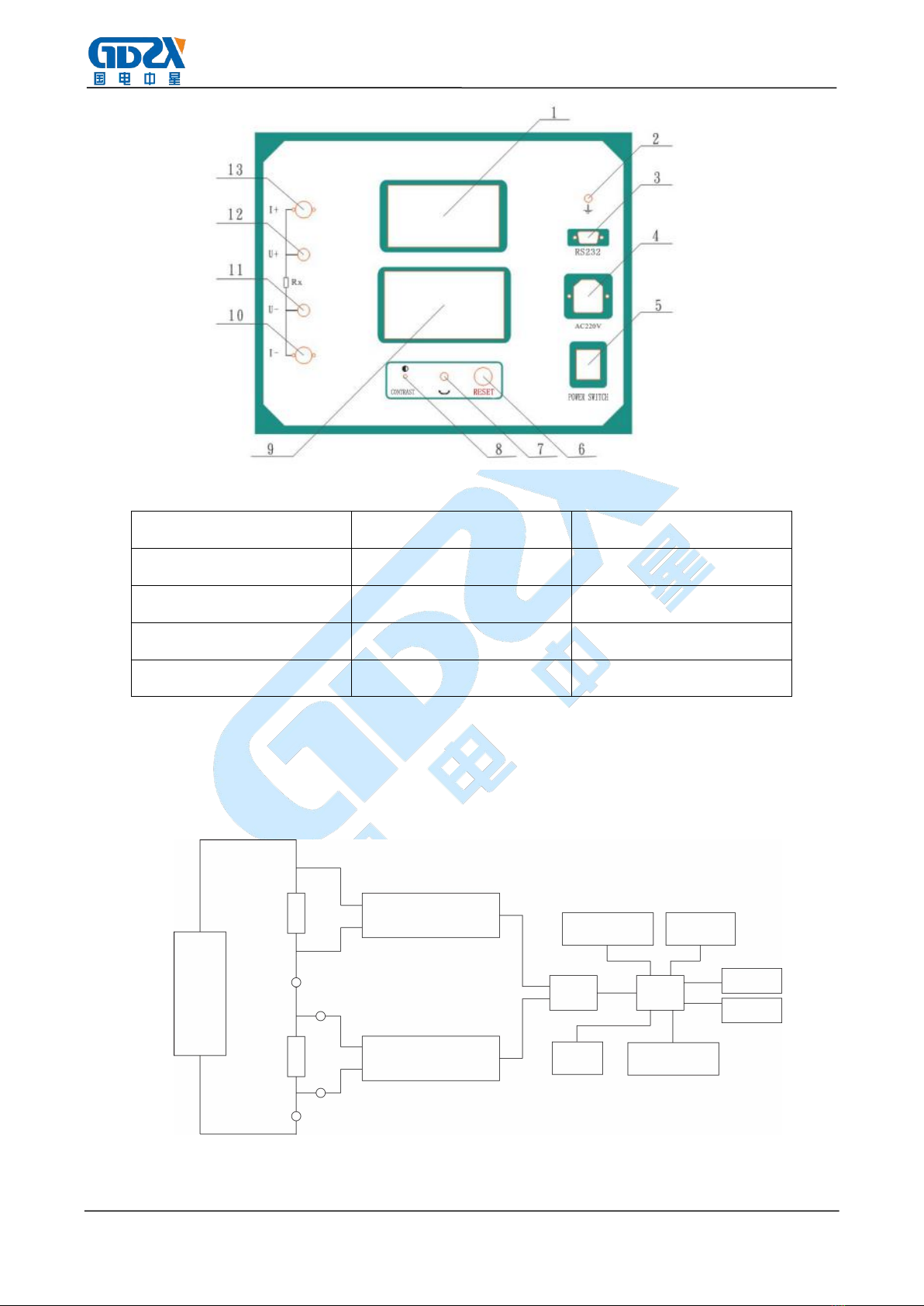

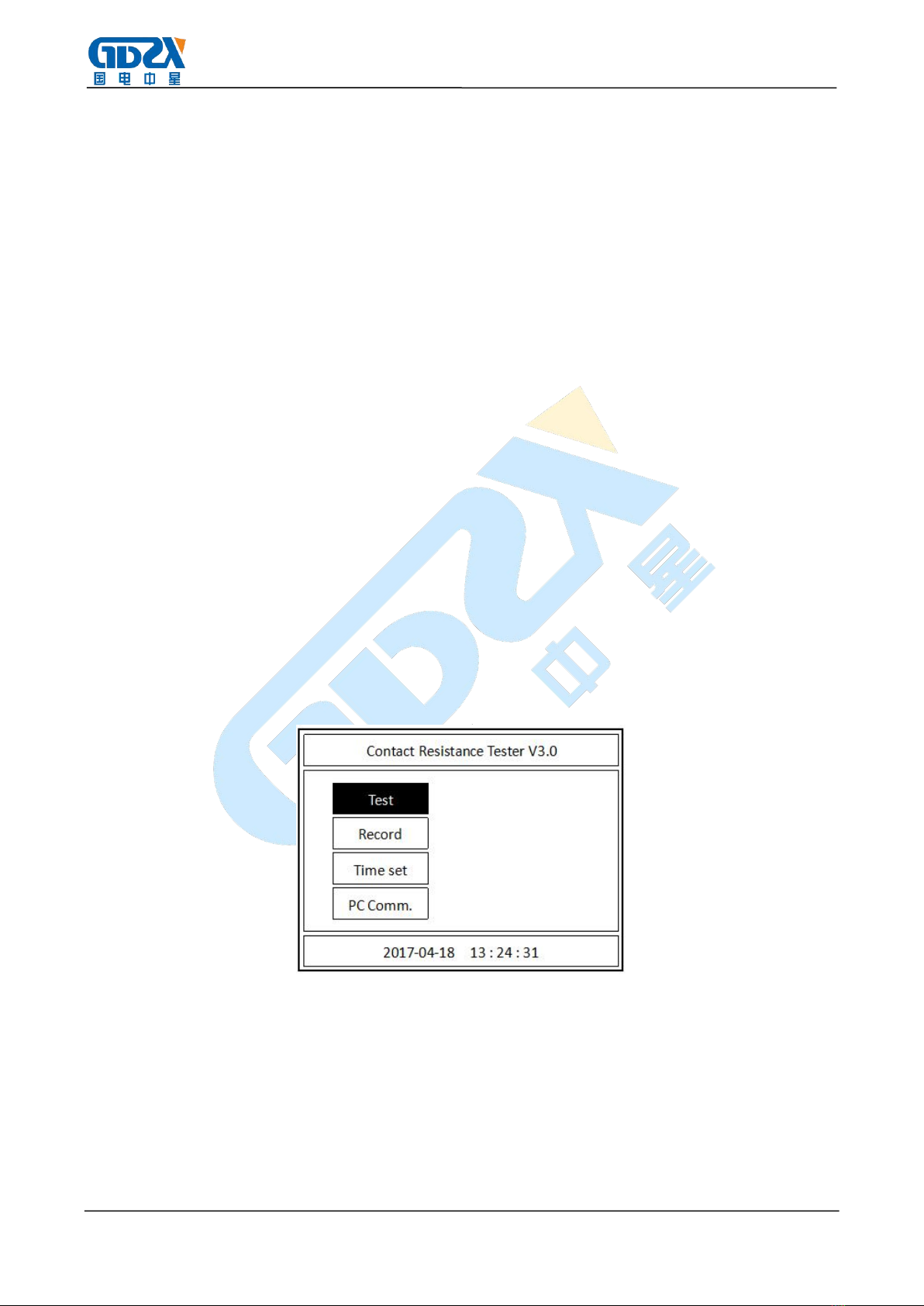

Is designed by using high-frequency switching power supply technology, combined with digital

circuit technology. It is suitable for measuring switching control equipment contact resistance. The

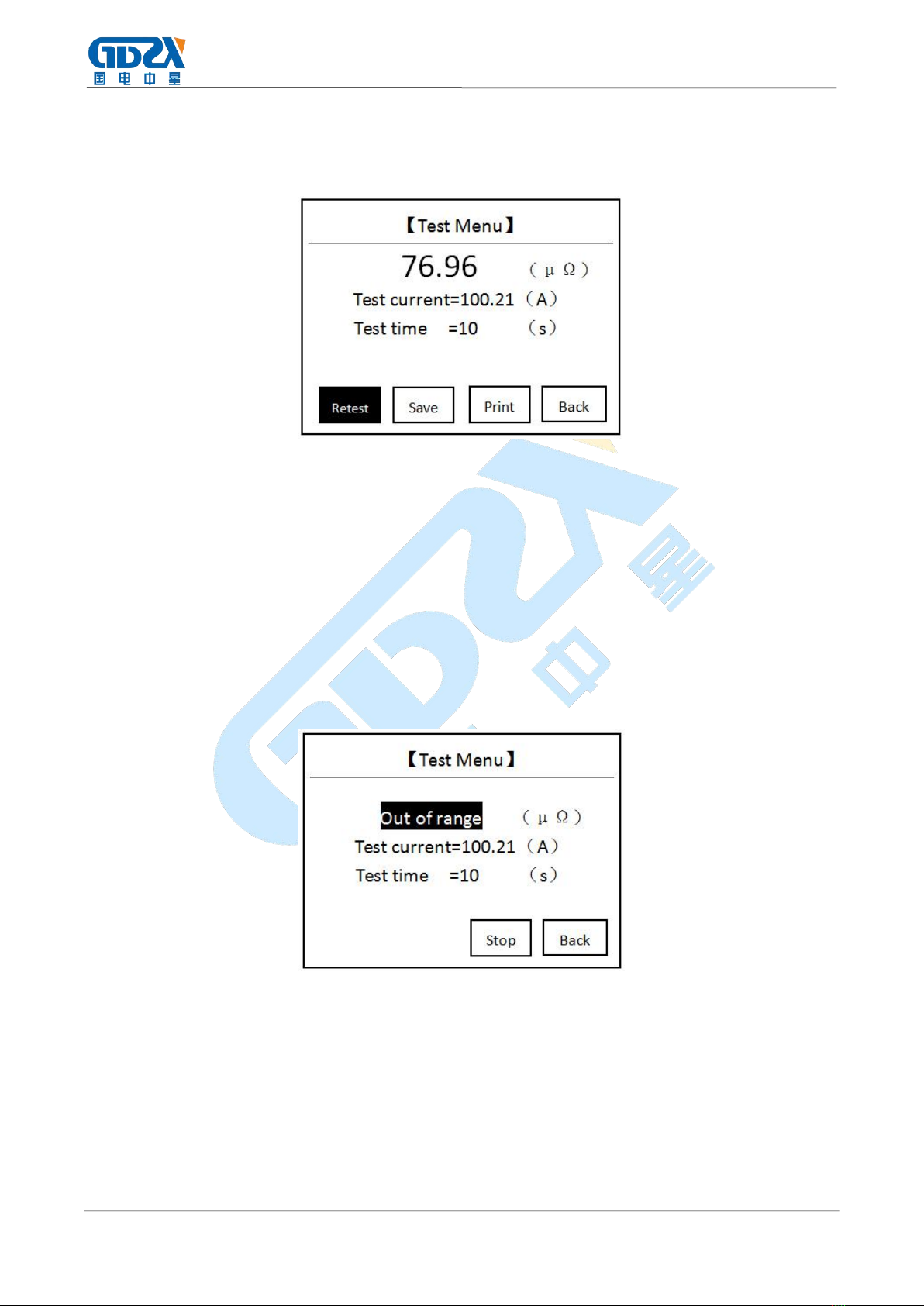

test current is national standards DC 100A. In the case of current 100A, contact resistance is

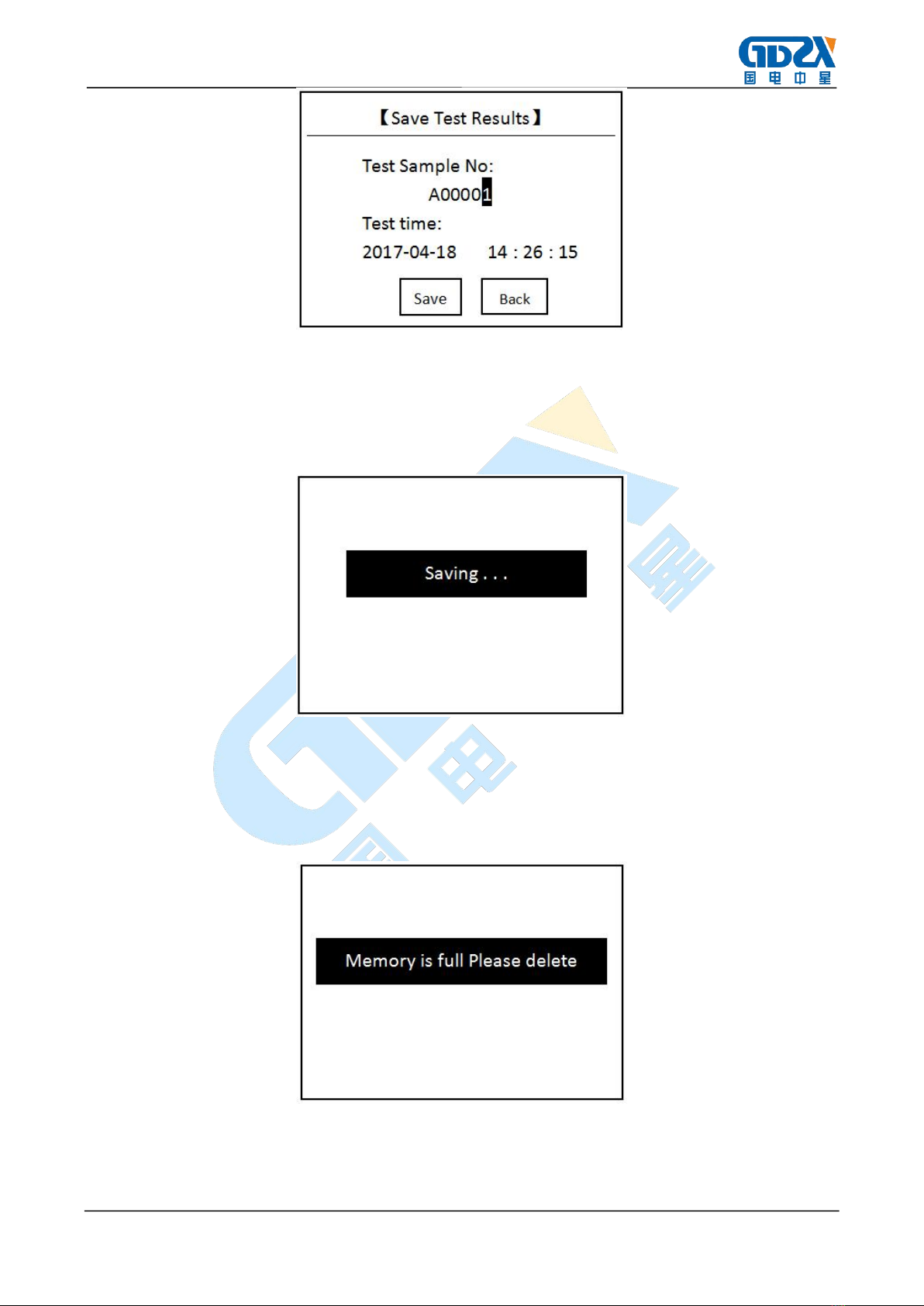

directly measured, the final test results show in large-screen LCD, with data storage, printing, time

settings and other functions. 50A also selectable. The instrument measurement is with high accuracy,

stable performance, able to meet the power industry, high-voltage switchgear maintenance and high

voltage switch factory contact resistance test requirements.

Ⅱ、Product Usage

Is suitable for high-voltage switch contact (loop) resistance measurement, it also applies to

occasion when need large current, micro resistance measurements

Ⅲ、Features

1. Use latest power supply technology, the tester can continuously output high current which

overcomes the weakness of instantaneous current produced by pulsed power. It can effectively

breakdown/puncture the oxide layer of the switches and then get precise

2. High stability. under strong interference, the last number displayed by the LCD is within the

range of ±1d, with steady reading and good reproducibility

3. High precision: adopts double channels high-speed 16bits Σ-Δ AD to sample, digital signal

processing technique, the maximum resolution up to 0.01μΩ.

4. Intelligent: use high performance CPU, system can switch the measurement range according the

size of the signal during testing to ensure the accuracy. The over-temperature protection circuit

can auto stop output the current when the device exceeds the rated temperature to ensure the

safety.