ZXR-40A

- 9 -

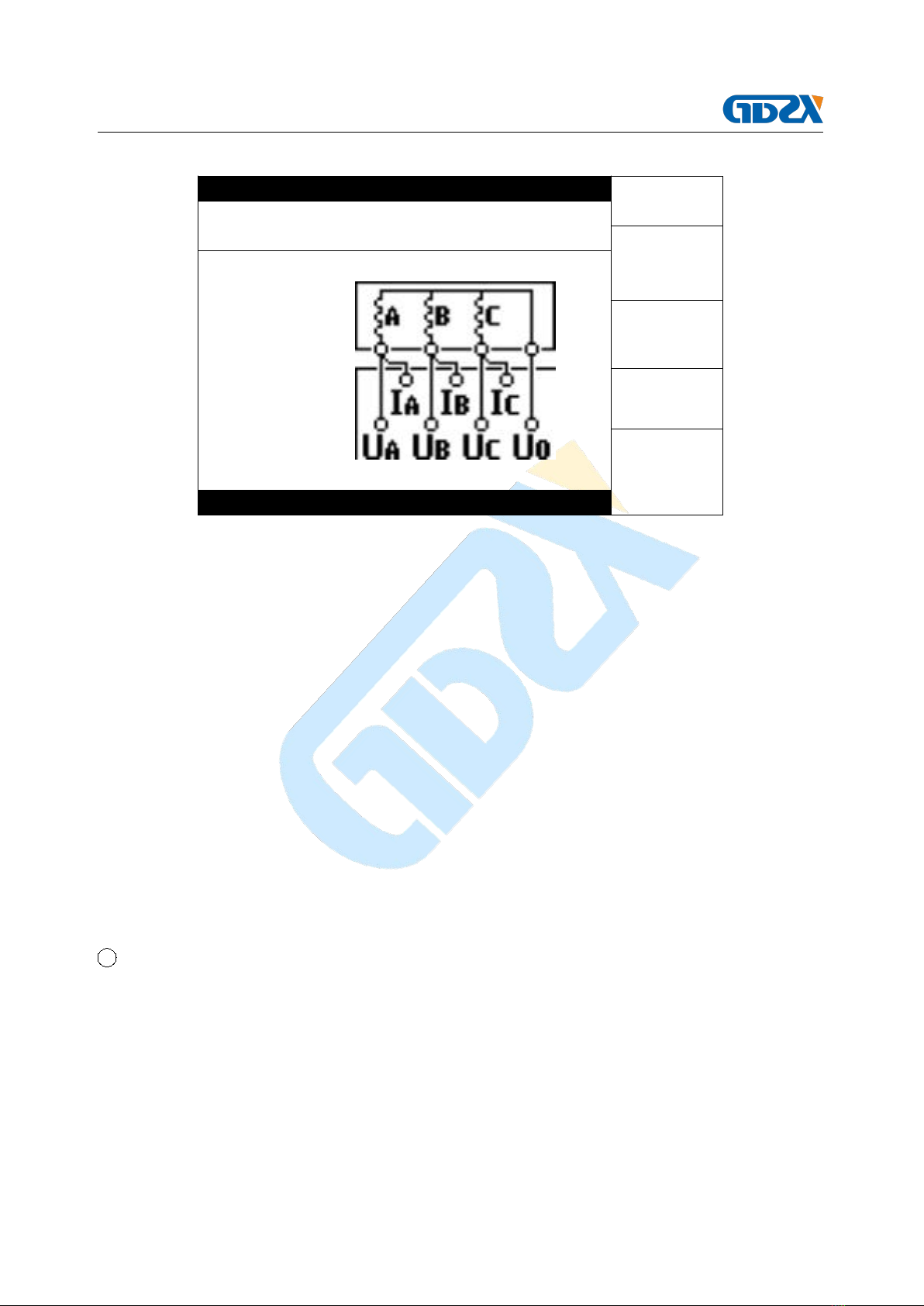

Imbalance rate: 00.28 %

Current tap : 0 1

Now, the dc resistance tester starts to display the resistance value of each phase. With the

resistance value of each phase becoming stable, the imbalance rate will gradually decrease.

Under such state, the “Tap” button may be pressed to adjust and set the current tap value or

winding name so as to mark the measurement result. After the “Tap” button is pressed down, the

multi-functional key on the right becomes “▲”“▼”“ ”“OK” and “Cancel”, and the tap

setting dialogue box is ejected. After setting, press the “OK” button to save it and press the

“Cancel” button to modify it. Then, press “Store” and “Print” button to save or print the

measurement results. In case of any doubt about the data, press “Retest” button to carry out the

measurement and calculation again. The maximum display scope of the imbalance rate is 50%. If

such scope is exceeded, only “50%” will be display.

When measuring the on-load voltage changing transformer, after the testing data of one tapping

position becomes stable, the on-load tapping switch may be switched to the next tapping position,

without discharging to conduct the measurement over again. At this time, the resistance value

and imbalance rate of each phase will change gradually until they become stable. You may also

press “Re-test” button to quickly refresh the data. Repeat the above-mentioned procedure until

all the tapping tests are completed.

Upon the completion of the measurement, press the “Exit” key to end the measurement. At

this time, the DC resistance tester starts to discharge and the display gives corresponding

discharge indication and the buzzer rings. After the discharge is completed and the tester