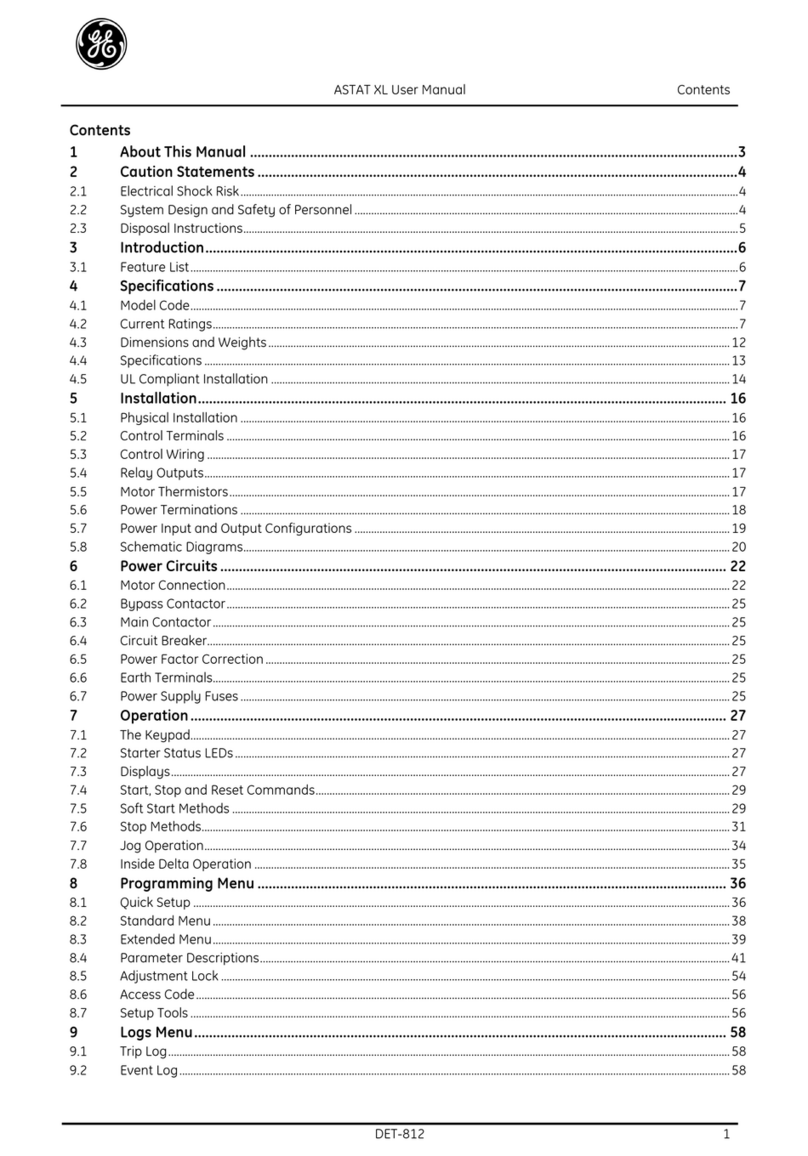

Contents

iv PACSystems* RXi Distributed IO Controller User Manual GFK-2816F

7.1.3 I/O Variables ................................................................................................121

7.1.4 Arrays...........................................................................................................123

7.1.5 Variable Indexes and Arrays........................................................................123

7.1.6 Ensuring that a Variable Index does not Exceed the Upper Boundary of an

Array.............................................................................................................125

7.2 Reference Memory................................................................................................ 126

7.2.1 Word (Register) References........................................................................126

7.2.2 Bit (Discrete) References.............................................................................128

7.3 User Reference Size and Default.......................................................................... 129

7.3.1 %G User References and CPU Memory Locations.....................................129

7.4 Transitions and Overrides..................................................................................... 130

7.5 Retentiveness of Logic and Data .......................................................................... 131

7.6 Data Scope............................................................................................................ 132

7.7 System Status References.................................................................................... 133

7.7.1 %S References............................................................................................133

7.7.2 %SA, %SB, and %SC References ..............................................................134

7.8 How Program Functions Handle Numerical Data ................................................. 136

7.8.1 Data Types...................................................................................................136

7.8.2 Floating Point Numbers ...............................................................................137

7.9 User Defined Types:.............................................................................................. 139

7.9.1 Working with UDTs ......................................................................................139

7.9.2 UDT Properties ............................................................................................139

7.9.3 UDT Limits ...................................................................................................140

7.9.4 Run Mode Store of UDTs.............................................................................140

7.9.5 UDT Operational Notes................................................................................140

7.10 Operands for Instructions...................................................................................... 141

7.11 Word-for-Word Changes....................................................................................... 142

Chapter 8 Gigabit Ethernet (GbE) Interface Overview and Operation....... 143

8.1 PACSystems Ethernet Interface Communications Features ................................ 144

8.2 Station Manager.................................................................................................... 144

8.3 IP Addressing........................................................................................................ 144

8.4 SRTP Server Operation ........................................................................................ 145

8.4.1 SRTP Inactivity Timeout ..............................................................................145

8.5 Modbus TCP Server Operation............................................................................. 146

8.5.1 Modbus Conformance Classes....................................................................146

8.5.2 Server Protocol Services .............................................................................146

8.5.3 Station Manager Support.............................................................................146

8.5.4 Reference Mapping......................................................................................146

8.5.5 Address Configuration .................................................................................148

8.5.6 Modbus Function Codes..............................................................................149