2

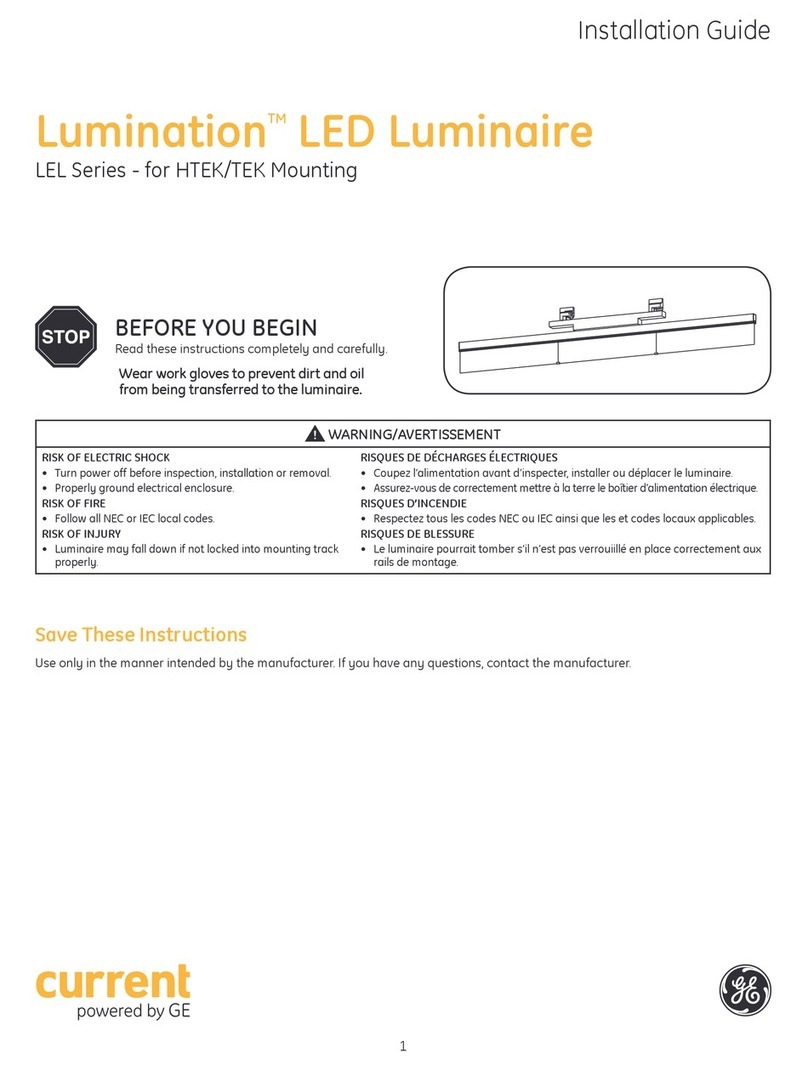

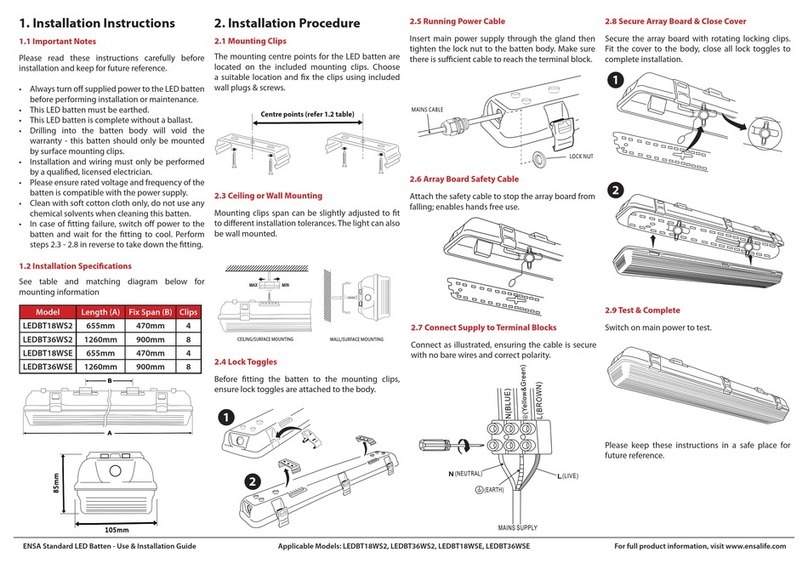

Important Notes for Installation

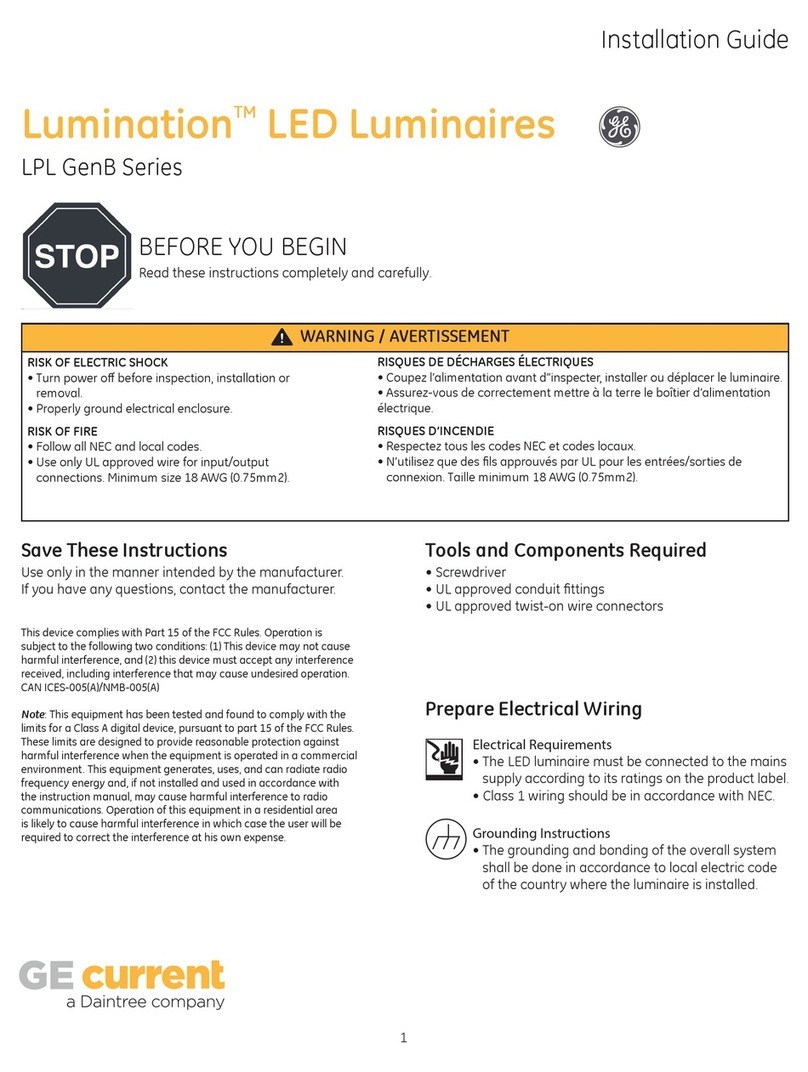

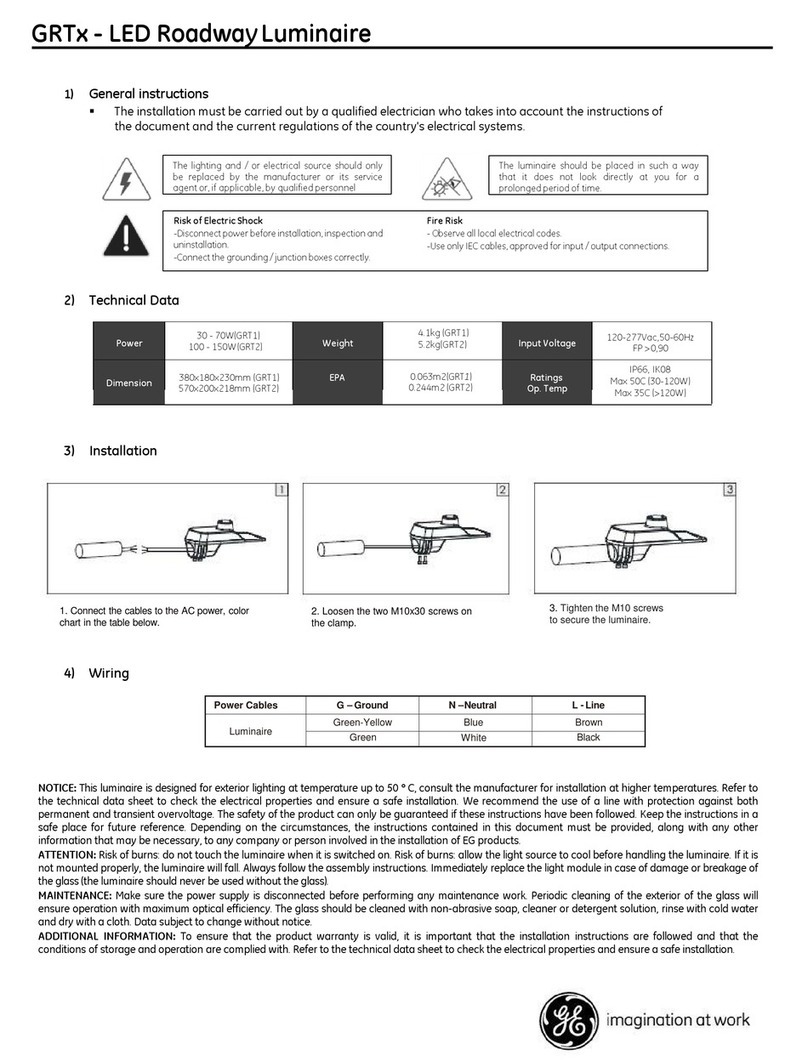

Prepare Electrical Wiring

Grounding Instructions

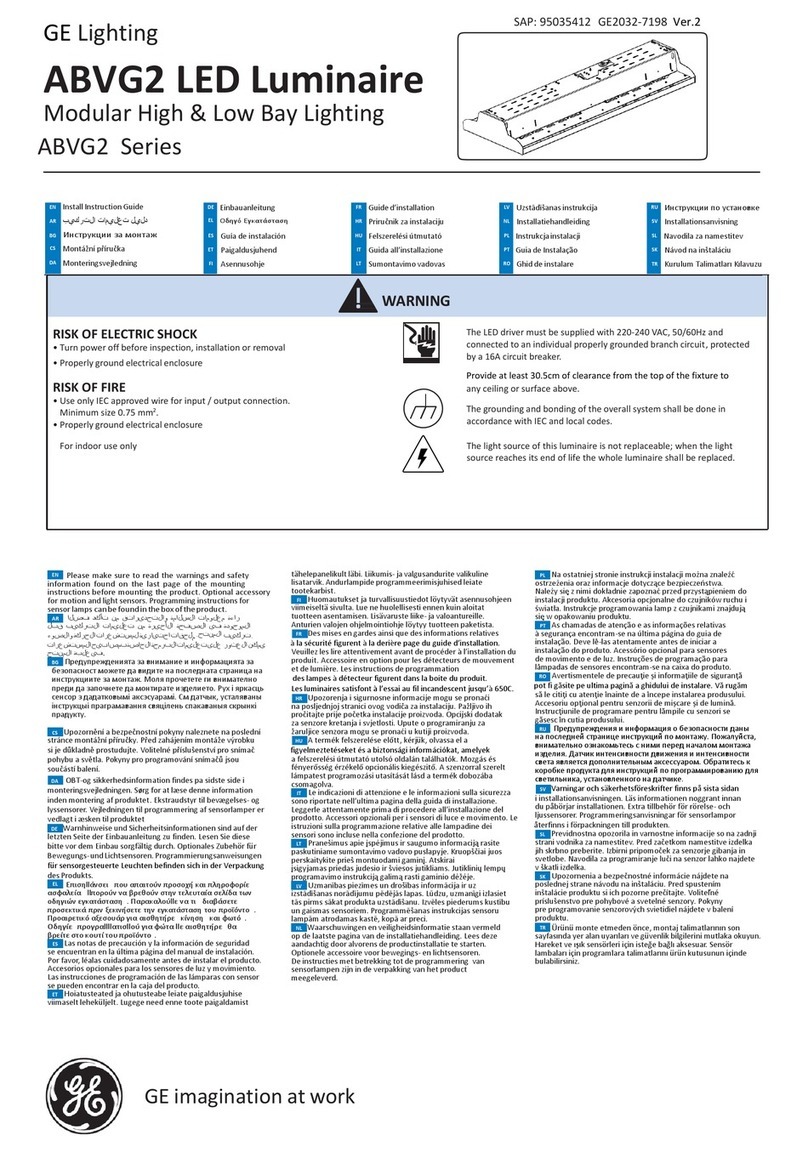

The grounding and bonding of the overall system

shall be done in accordance with National Electric

Code (NEC) Article 600 and local codes.

Electrical Requirements

The LED xture must be supplied with 120-277VAC,

50/60Hz and protected by a max. 20A circuit

breaker. Use min. 75°C supply conductor.

IMPORTANT - Maximum Length of Electrical Run

Voltage

Lumen Code

[42] [84] [52] [A0] [62] [A2]

120V 232’ 176’ 160’

277V 536’ 412’ 369’

IMPORTANT - Maximum Length of Electrical Run

Ensure that maximum safe working load of the xture’s suspension brackets is not exceeded after LUR retrot kit is added.

IMPORTANT - During Installation

1. When installing, use clean gloves in order to avoid fouling the reective surface.

2. To ensure a clean xture, install the xture with the plastic bag around the xture, and then remove plastic bag upon

completion of any and all construction related activity.

3. All provided screws must be screwed in and tightened to ensure that the retrot kit is safely attached to existing

luminaire. Max torque: 33 lbf-in.

4. Minimum distance from ceiling to luminaire: 3”.

5. Minimum distance between heat producing components: 3”.

6. Minimum size of enclosure: the existing luminaire being retrotted must have an electrical enclosure of 48” by 3” by

1.5” or greater.

7. It is recommended to use the optional tether kit (93064841) to ensure extra mechanical security on nal install.

8. Do not remove spacers on the brackets’ screws, as they are meant to stay on screws after installation.

9. Cap 0-10V dimming gray and purple wires (see Wiring Diagram) if not in use.

Save These Instructions

These instructions do not purport to cover all details or variations in components nor to provide for every possible

contingency to be met in connection with installation, operation or maintenance. Should further information be desired

or should particular problem arise which are not covered sufciently for the purchaser’s purpose, the matter should be

referred to General Electric Company. GE does not claim liability for any installation not performed according to this

guide or not by a qualied electrician.

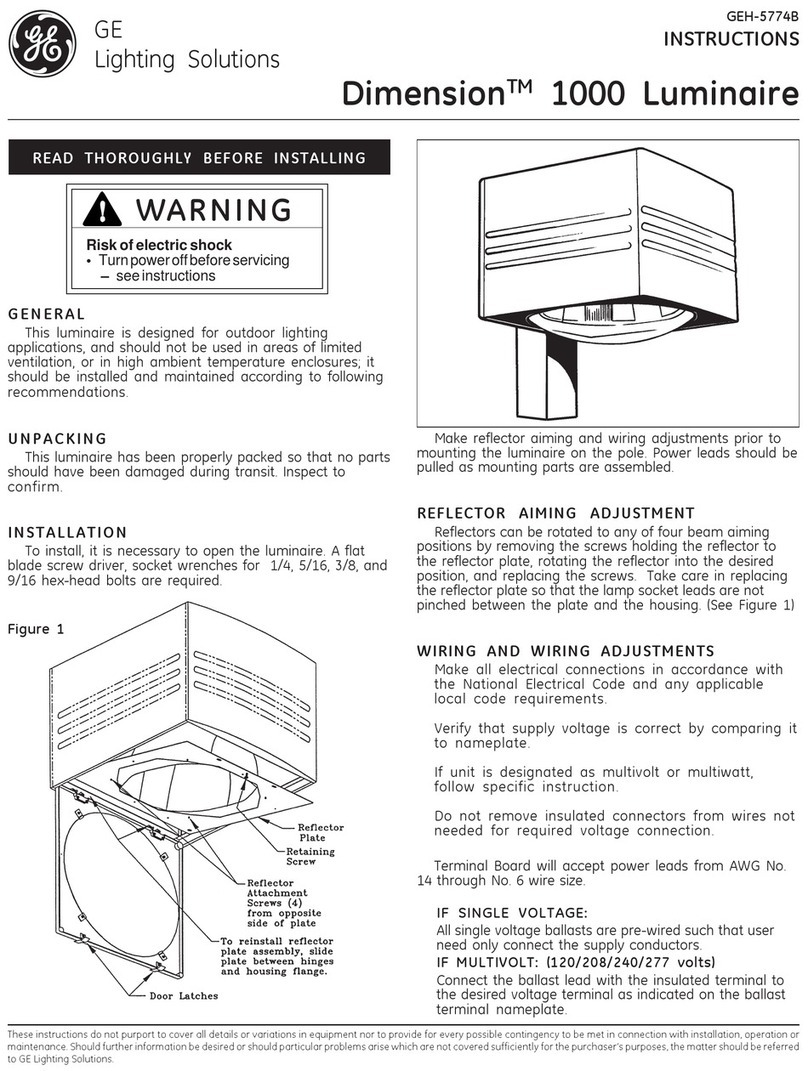

Required Tools

• Wire cutters/strippers

• Portable drill with 1/4” hex drive bit

• Punch tool 1/4”

• Screwdriver for ballast mounting screws