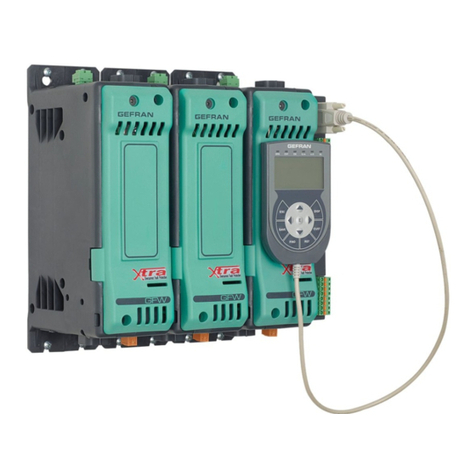

eView BOX

Inside Control Panel Controller

QUICK INSTALLATION GUIDE

Side 1 Warnings and safety

Technical data

Mounting

Side 2 Connections

Dimensions

code 81673 - 04/2019 - ENG

WARNING and SAFETY

MOUNTING

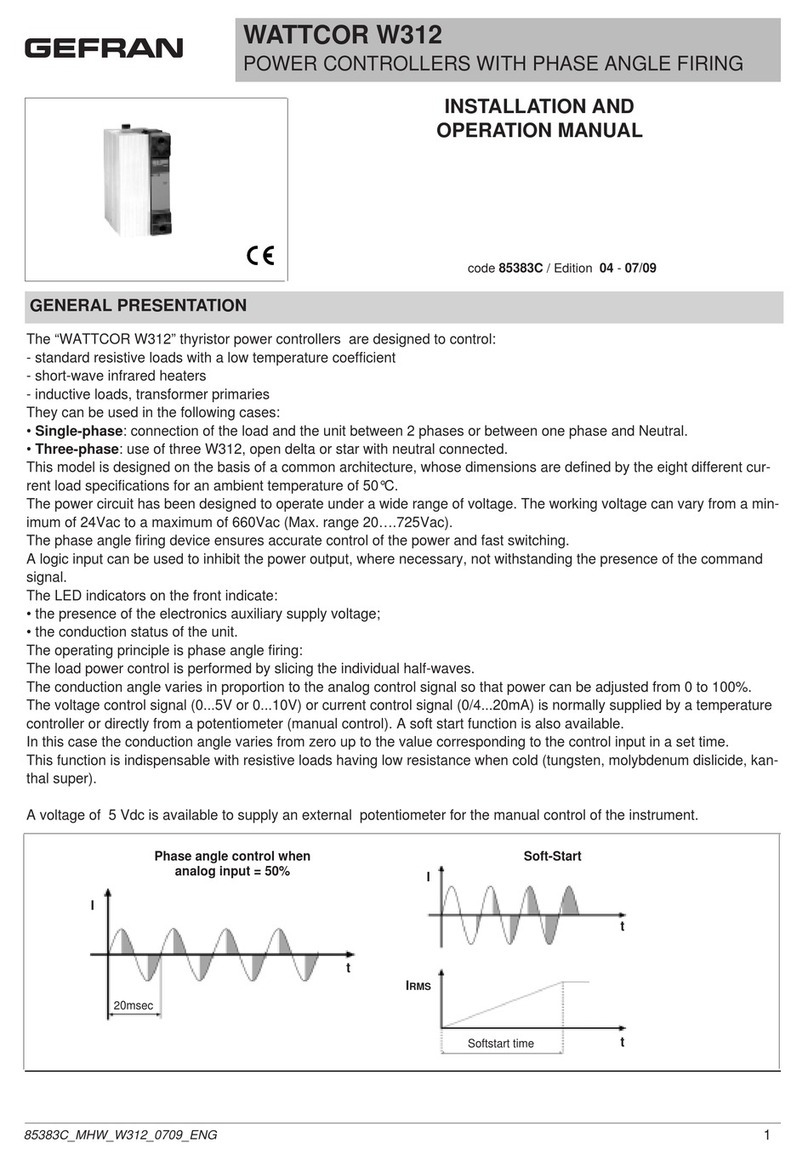

GEFRAN spa

via Sebina, 74 - 25050 Provaglio d’Iseo (BS)

Tel. 03098881 - fax 0309839063- Internet: http://www.gefran.com

While all the information contained in this manual has been carefully checked, Gefran S.p.A. accepts

no responsibility for the possible presence of errors or for damage to persons and/or property caused

by the improper use of the manual.

Gefran S.p.A. also reserves the right to make changes to the contents and form of this manual and to the charac-

teristics of the devices illustrated at any time and without prior warning.

The installation of the devices illustrated in the manual must be carried out by qualied technicians in compliance with

the laws and standards in force and in agreement with the instructions contained in the manual.

If the eView BOX is used in applications with the risk of damages to persons, machinery or materials, its use in con-

junction with alarms is essential.

It is advisable to envisage the possibility of checking the intervention of the alarms during regular operation.

Before interacting with the Inside Control Panel Controller, the operator must receive full training in the procedures of

operation, emergency, diagnostics and maintenance of the system.

More information on the device and its installation, maintenance and use procedures can be found in the product’s

Installation and User Manual, available for download on the website www.gefran.com.

Graphic simbol

Indicates contents of sections, general instructions, notes, and other points to which the reader’s attention needs to be

called.

Indicates a particularly delicate situation that could affect the safety or correct operation of the controller, or an instruction

that MUST be followed to prevent hazards.

TECHNICAL DATA

NOTES ON ELECTROMAGNETIC COMPATIBILITY:

CE: Conformity EMC (electromagnetic compatibility) in compliance with Directive 2014/30/EU.LV

EN61131-2: Programmable controllers

Part 2: Equipment requirements and test.

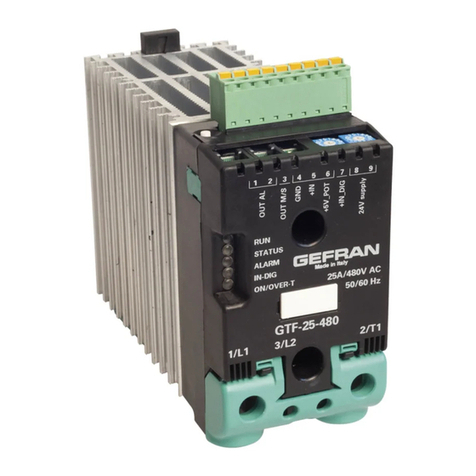

eView BOX

POWER SUPPLY

Operating voltage 24 VDC ±25%

Current draw (at 24 VDC) 500 mA max

Power dissipation 12 W max

Protections Polarity inversion

Short circuit

Connection 3-pin polarized removable connector

Screw terminals, max cable section 2.5 mm2

CONNECTIONS

Ethernet port (ETH) Number of channels: 2 max (1 optional)

Connector: RJ45

Velocity: 10 / 100 / 1000 Mbit/s

Signals: green connection LED, yellow data LED

KEY & LED port Connector: RJ45

Standard: USB2.0

RS-232 port (optional) Connector:: DB9 M

Speed: 1.2kbit/s…115kbit/s

RS-485 port (optional) Optically isolated

Connector: DB9 M

Speed: 9 kbit/s … 19 kbit/s

Terminations and polarization: internal, selectable with

jumper

CAN port (optional) Optically isolated

Connector: DB9 M

Speed: 20, 50, 100, 125, 250, 500, 1000 kbit/s, default

500 kbit/s

Termination: internal, selectable with jumper

USB port

Number of ports: 2 max

Connector: type A

Standard: USB 2.0

Protection: overload

COMMUNICATION

PROTOCOLS

Ethernet FTP (File Transfer Protocol) Modbus TCP/IP Master/

Slave

Ethercat Master

GDNET Master

CAN CANopen Master

Modbus Modbus RTU Master/Slave

CONFIGURATION

ELEMENTS Access to software procedures 16-position rotary switch

CONTROL

ELEMENTS Touch screen 4-wire resistive technology

VIEWING ELEMENTS

Diagnostics PW LED (yellow): power supply on

RN LED (green): PLC program state

LED E1 (red): HW Watchdog state

LED E2 (red): PLC program error

MICROPROCESSOR Type and frequency ATOM E620, 0.6 GHz

ATOM E660, 1.3 GHz

MEMORY

System 512 MB, DRAM type DDR II

Mass 2 GB Flash memory

Mass extension SD Card Slot *

AMBIENT

CONDITIONS

Operating temperature 0 ... +55 °C (as per IEC 68-2-14)

Storage temperature -20 ... +70 °C (as per IEC 68-2-14)

Relative humidity max 95% RH non condensing (as per IEC 68-2-3)

Vibrations 5 to 9 Hz: sine constant 3.5 mm

10 to 150 Hz: sine acceleration 1G

ASSEMBLY Mounting inside the control panel, horizontally with the

DIN bar or vertically with xing screws.

PROTECTION LEVEL IP 20 (as per IEC 68-2-3)

WEIGHT 1.250 kg

EC REGULATIONS

EMC conformity

(Electromagnetic compatibility)

Compliance with the 2014/30/EU Directive

EN61131-2: Programmable controllers

Part 2: Equipment requirements

* SD card not supplied. Available as accessory

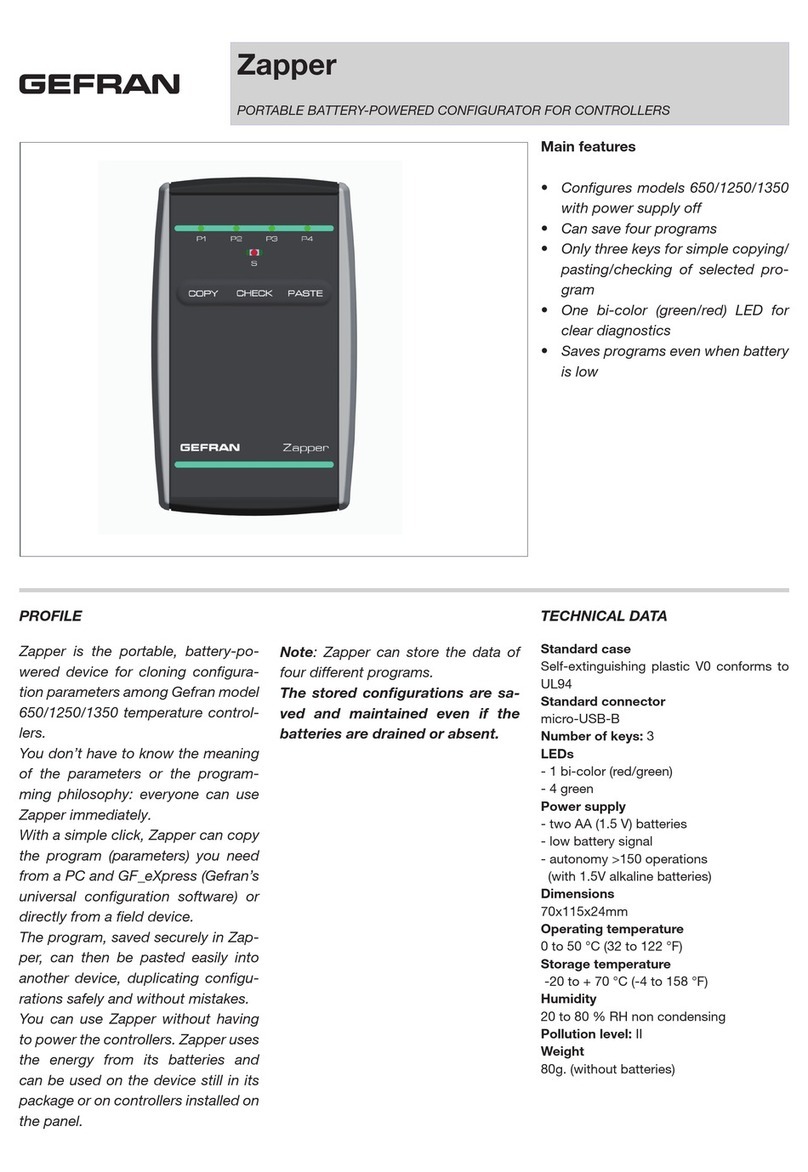

Fig. 2

18

26.6

217

15

5.5

Hole dimensions

For correct installation, comply with the dimensions

of the drilling templates shown in Fig.1 and the

dimensions of the space requirements in Fig.12.

Installation note

The plate on which the Inside Control Panel

Controller is mounted must:

•be sufciently stiff and strong to support the

device and not bend during use;

• have a minimum thickness of 2 mm to allow the

holes to be threaded properly;

• have an M5 threading.

Protection against inltrations of water

The Inside Control Panel Controller offers a degree

of protection of IP20.

When it is necessary to use the product in

environments that require a protection rating greater

than IP20, that rating must be guaranteed by the

control panel where the controller is installed.

Vibration

The Inside Control Panel Controller can support

vibrations up to 150 Hz:

• from 5 to 9 Hz: sinusoidal 3.5 mm constant;

• from 9 to 150 Hz: sinusoidal with acceleration

equal to 1 G.

Should the device be mounted on a support that

exceeds these limits it is necessary to envisage

a system for the suspension and mitigation of the

vibration.

Minimum spaces for ventilation

The temperature of the compartment that

houses the Control Panel must not exceed,

55 °C.

Figure 2- Free spaces for ventilation shows the

minimum free distances recommended in the

installation of the device in a closed compartment.

Positioning

The Inside Control Panel Controller must be

positioned to guarantee the following conditions:

• there must be no sudden temperature changes;

• there must be a low explosion risk: it can

be connected to elements that operate in

environments with a hazardous atmosphere

(ammable or explosive) only through appropriate

and suitable types of interface, compliant to the

safety standards in force;

• low presence of magnetic elds.

Fastening

The Inside Control Panel Controller can be installed

in two ways:

• horizontal on DIN 35 mm track, Fig.4A.

• vertical, Fig.4B.

• Horizontal mounting:

Install the 2 brackets for the DIN 35 track as shown

in Fig.3. Fasten the product and press hard to

complete the operation, rotating downwards.

• Vertical mounting:

Prepare the M5 threaded holes, done with the

template as shown in Fig.1, position the product

and screw in place as shown in Fig.4. Warning:

install locking washers to prevent the screws from

loosening!

Fig. 1

WEEE Information

Pursuant to Article 26 of Italian Legislative Decree no. 49 of 14 March 2014 “Implementation of

Directive 2012/19/EU on waste electrical and electronic equipment (WEEE)”.

The symbol showing a crossed-out wheeled bin on equipment or its packaging indicates that the product must be

collected separately from other waste at the end of its useful life.

The manufacturer is responsible for organising and managing the separate collection of this piece of equipment

at the end of its useful life.

Users wishing to dispose of the equipment must therefore contact the manufacturer to obtain instructions from the

same on how to have the equipment collected separately at the end of its useful life.

By collecting the disused equipment separately, it can be recycled, treated or disposed of in an environmentally

friendly manner, thus helping to prevent the environment and public health from being affected negatively and

enabling reuse and/or recycling of the materials forming the same equipment.

Fig. 3

Fig. 4