6 Order data

The order data provide an overview of standard configurations.

Please check the availability before ordering. Other configurations available on request.

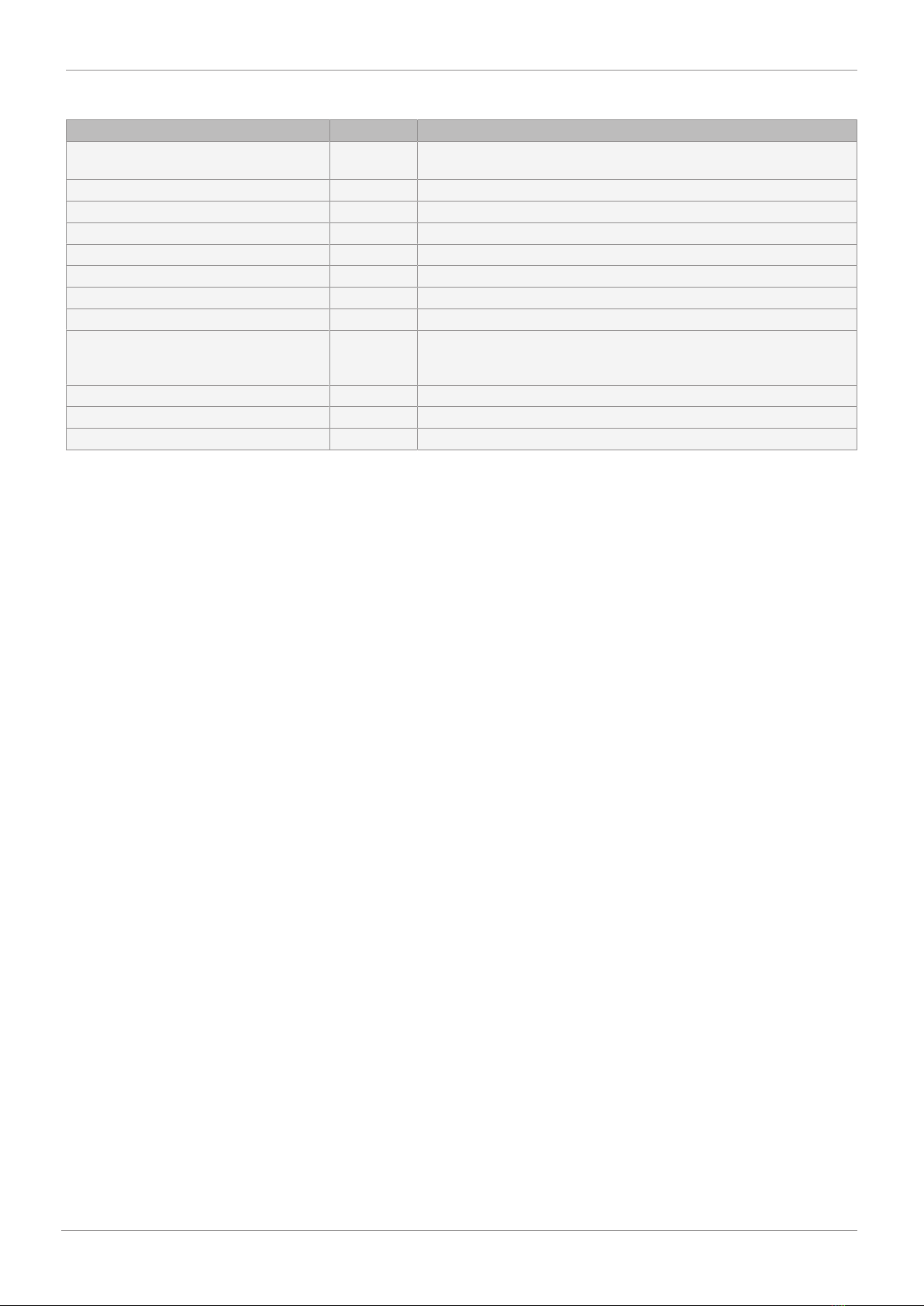

Order codes

1 Type Code

Angle seat globe valve, electrically operated,

eSyStep

543

2 DN Code

DN 6 6

DN 8 8

DN 10 10

DN 15 15

DN 20 20

DN 25 25

3 Body configuration Code

2/2-way body D

Angle valve body E

4 Connection type Code

Spigot

Spigot DIN 0

Spigot EN 10357 series B,

formerly DIN 11850 series 1

16

Spigot EN 10357 series A (formerly DIN 11850

series 2)/DIN 11866 series A

17

Spigot DIN 11850 series 3 18

Spigot SMS 3008 37

Spigot ASME BPE 59

Spigot ISO 1127/EN 10357 series C/DIN 11866

series B

60

Spigot ANSI/ASME B36.19M schedule 10s 63

Spigot ANSI/ASME B36.19M schedule 40s 65

Threaded connection

Threaded socket DIN ISO 228 1

Threaded socket BS 21 Rc,

end-to-end dimension ETE DIN 3202-4 series M8

3C

Threaded socket NPT,

end-to-end dimension ETE DIN 3202-4 series M8

3D

Threaded spigot DIN ISO 228 9

Flange

Flange EN 1092, PN 25, form B,

face-to-face dimension FTF EN 558 series 1, ISO

5752, basic series 1

10

Flange EN 1092, PN 25, form B 13

Flange ANSI Class 150 RF 47

Clamp

Clamp ASME BPE,

face-to-face dimension FTF ASME BPE

80

Clamp DIN 32676 series B,

face-to-face dimension FTF EN 558 series 1

82

4 Connection type Code

Clamp DIN 32676 series A,

face-to-face dimension FTF EN 558 series 1

86

Clamp ASME BPE,

face-to-face dimension FTF EN 558 series 1

88

5 Valve body material Code

1.4435, investment casting 34

1.4408, investment casting 37

1.4435 (F316L), forged body 40

1.4435, investment casting C2

6 Seat seal Code

PTFE 5

PTFE, glass fibre reinforced 5G

1.4404 10

7 Voltage/frequency Code

24 V DC C1

8 Control module Code

Positioner S0

Positioner, configured for emergency power

module (NC)

S5

Positioner, configured for emergency power

module (NO)

S6

9 Regulating cone Code

without

Please find the number of the optional regulating

cone (R-No.) for the linear or equal-percentage

modified regulating cone in the Kv value table.

R….

10 Actuator version Code

Actuator size 0 0A

11 Type of design Code

without

Ra ≤ 0.6 μm (25 μinch) for media wetted surfaces,

in accordance with ASME BPE SF2 + SF3

mechanically polished internal

1903

Ra ≤ 0.8 µm (30 µinch) for media wetted surfaces,

in accordance with DIN 11866 H3,

mechanically polished internal

1904

Ra ≤ 0.4 μm (15 μinch) for media wetted surfaces,

in accordance with DIN 11866 H4, ASME BPE SF1

mechanically polished internal

1909

Spindle seal PTFE-PTFE 2013

12 CONEXO Code

without

Integrated RFID chip for electronic identification

and traceability

C

6 Order data

www.gemu-group.com 7 / 64 GEMÜ 543

Positioner (Code S0)