10

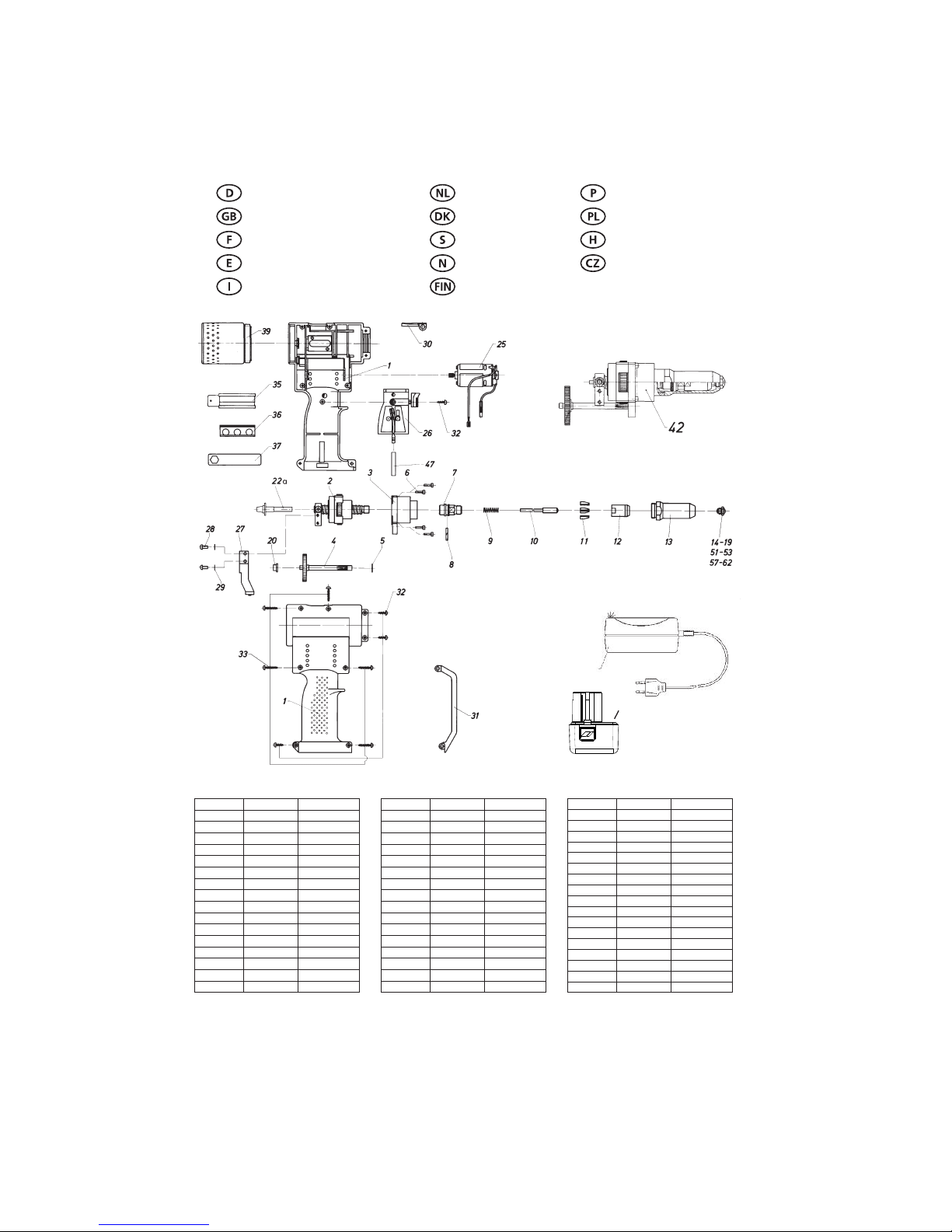

1.4. Nosepiece table

!

1.5. Safety instructions

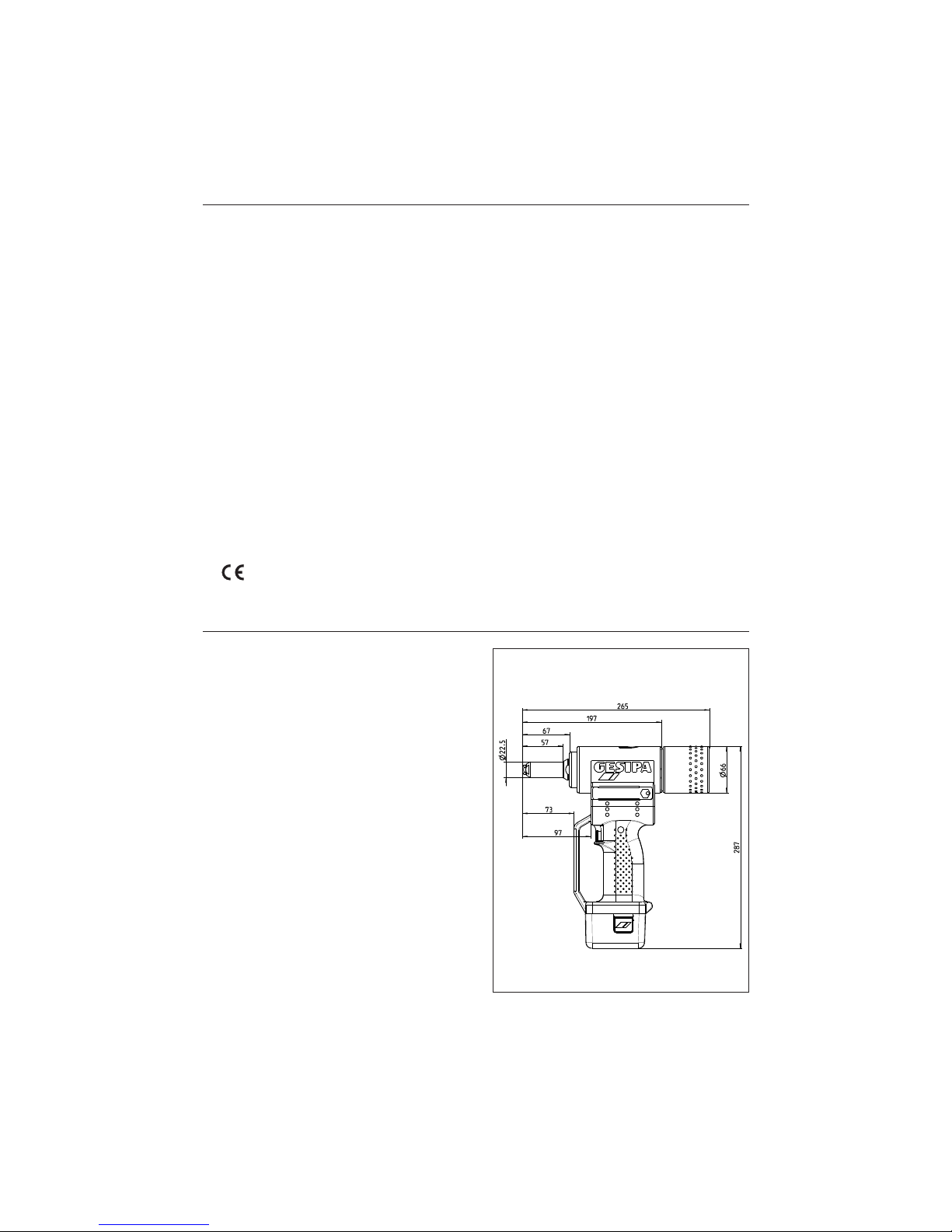

Blind rivet setting tool AccuBird®

Caution:

Following safety rules must be followed

for adequate protection against electrical schock,

injuries or fire hazards:

•The riveting tool should be used exclusively

to set blind rivets.

•Do not overload the tool; Work within the

prescribed work capacity.

•Do not expose the tool to humidity or rain,

do not operate the tool close to inflammable

substances or gases: Risk of explosion!

•Ensure that the battery is properly secured in

the tool handgrip.

•Remove the battery when the tool is not in use

and for repair/servicing operations.

•Do not use the tool as a hammer.

•When not in use, keep the tool in a dry closed

room, out of reach of children.

•When working with the tool, always carry

protection goggles. Personal protection like

clothes, gloves, safety helmet, non slipping

shoes, ear protectors and protection against

fall are highly recommended.

•The air inlets for the engine should not be

obstructed. Do not introduce anything into them.

•When depositing the tool, make sure that it

cannot fall down.

•Use only genuine spare parts for repair.

•Repair work must be carried out by skilled

personal. In case of doubt, always send back

the tool to the manufacturer!

•Do not use the tool outside of riveting holes.

The blind rivet could be ejected from the tool.

Never turn the tool towards yourself or towards

another person.

* available as special accessories. Elongated nosepieces and other special nosepieces are available

upon request.

** Also available as a complete set (# 50) part no. 725 9290.

Rivet Ø (mm) Rivet body material Nosepiece Part.-No.

2,4 Alum 17/18**725 2075

3,2 CAP-Alum, CAP-CU 17/18**725 2075

3 and 3,2 Alum, CU, Steel, Stainless Steel, Stinox, 17/24*725 1583

Alum/Alum, PG-Alum, PG-Steel, PG-Stainless Steel *

4Alum, CU, CAP-Alum, CAP-CU 17/24*725 1583

4 Steel, Alum/Alum, PG-Alum 17/27*725 2040

4Stainless Steel, Stinox, PG-Steel, PG-Stainless Steel 17/29*725 2059

4,8 and 5 Alum, CAP-Alum, CAP-CU, PG-Alum 17/29*725 2059

4,8 and 5 Steel, Alum/Alum 17/32*725 2067

4,8 and 5 PG-Steel, PG-Stainless Steel, G-Bulb 17/36* 725 2083

6 Alum 17/36* 725 2083

BULB-TITE Ø (mm)

Rivet body material Nosepiece Part.-No.

4 Alum/Alum 17/26 BT**725 2202

5,2 Alum/Alum 17/32 BT**725 2210

6,3 Alum/Alum, Steel/Steel 17/42 BT***725 2229

BULB-TITE Ø (mm)

Rivet body material Jaw Pusher BT Part.-No. Jaws BT Part.-No.

6,3 Alum/Alum, Steel/Steel 54** 725 2245 55***715 1527