18

GB

Table of Contents

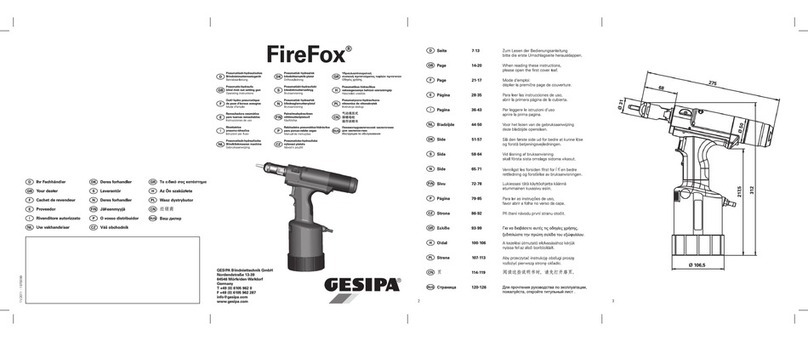

1. Overview (see Fig. 1 - 5).................................................................................19

2. Blind rivet nut setting tool.............................................................................19

2.1 Use for intended purpose ...........................................................................19

2.2 Safety information ......................................................................................19

2.3 Working range ............................................................................................20

2.4 Equipment/accessories ..............................................................................20

2.5 Technical data ............................................................................................20

2.6 Threaded mandrels/nosepieces .................................................................21

2.7 Start-up.......................................................................................................21

2.7.1 Setting the threaded mandrel length x (Fig. 2) ..................................21

2.7.2 Adjusting the setting stroke y (Fig. 2) ................................................21

2.8 Functional principle ....................................................................................22

2.8.1 Screwing on a blind rivet nut .............................................................22

2.8.2 Setting a blind rivet nut......................................................................22

2.8.3 Changing the threaded mandrel (Fig. 3) ...........................................23

3. Quick charger and battery.............................................................................23

3.1 Technical data ............................................................................................23

3.1.1 Quick charger ....................................................................................23

3.1.2 Rechargeable battery ........................................................................23

3.2 Safety information ......................................................................................24

3.2.1 Quick charger ....................................................................................24

3.2.2 Rechargeable battery ........................................................................24

3.3 Charging procedure....................................................................................25

3.4 Battery care ................................................................................................25

3.5 Environmental protection............................................................................26

4. Repairs ............................................................................................................26

5. Troubleshooting .............................................................................................26

5.1 Blind rivet nut does not screw on ...............................................................26

5.2 Set blind rivet nut is loose ..........................................................................27

5.3 Threaded mandrel is not unscrewed ..........................................................27

5.4 Red lamp indicates fault .............................................................................27

6. Warranty ..........................................................................................................28

7. CE Declaration of conformity........................................................................28