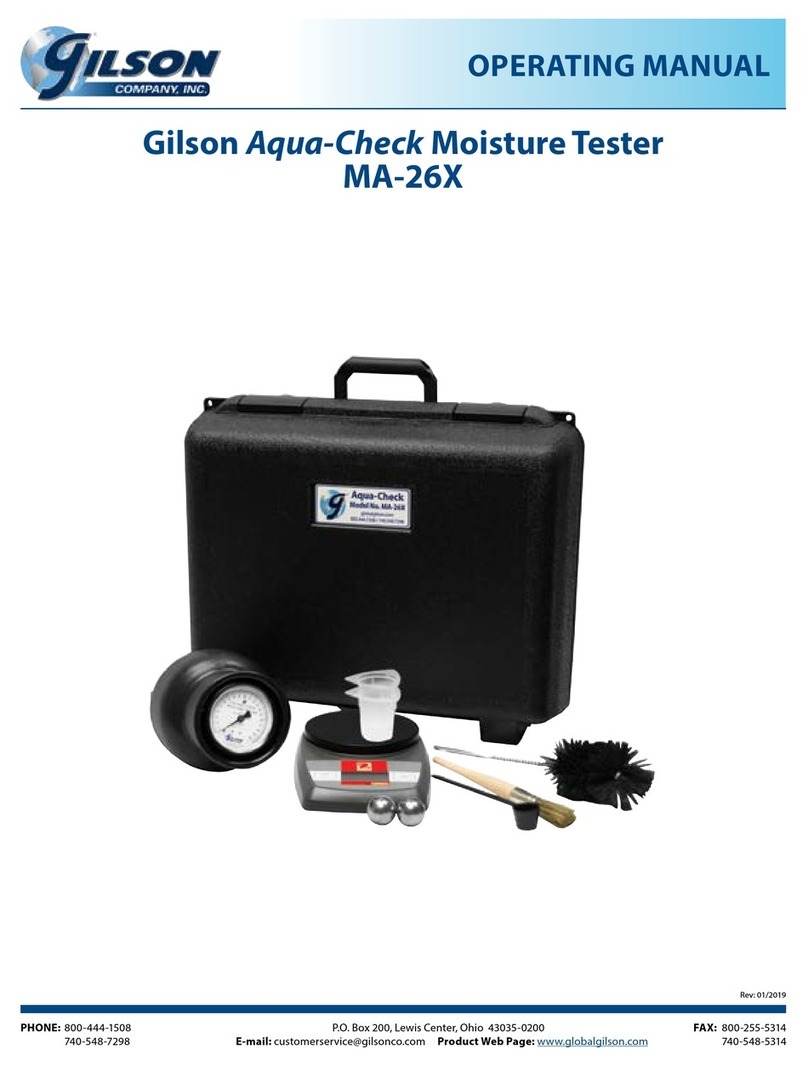

Gilson Aqua-Check Moisture Tester, MA-26X 7

STEP 9.Takinggreatcarethattheblackdotonthe

chamber cap is facing away from your face and body,

slowlyloosenthetopscrewtoventpressurizedgasfrom

thevessel.

STEP 10.Place theusedsample/reagent mixtureand

residue in an open dry container and dispose of in

accordance with local regulations or Section 13 of the

MSDS.UsetheCoarse-BristleBrushtocleanthevessel

andprepareforthenexttest.

S TE P 7. Agitatingthesample:

a.

Without Pulverizing Balls: HoldtheAqua-Check

vertically with the gauge facing down and agitate

vigorouslyfor5–10seconds.TurntheAqua-Check

around,andwiththegaugefacingupagitateagain

for5–10seconds.Tapthesidessothatthesample

fallsintothechambercap.Thisprocessshouldbe

repeatedfor1–3minutes,oruntilthegaugereading

inStep8hasstabilized.

b.With Pulverizing Balls:HoldtheAqua-Check

horizontallyanduseanorbitalmotiontospinthe

balls around inside the chamber, pulverizing the

sample. Agitate for 20 seconds and rest for 20

seconds, repeating the process at least three

times.Periodicallycheckthepositionofthegauge

indicator. Continue the agitation cycle until the

indicatorhasstabilized.Somehighlyplasticclays

mayrequire3minutesormoreofagitation.

STEP 8. Read the pressure gauge at eye level

whileholding thevessel horizontally.Waitforthe

indicatorneedletostopmoving.Thegaugereads

directly in percent water content of wet weight.

Accuracy may be improved by establishing a

correctionchartasshowninASTMD4944.

STEP9:Looseningtopscrewtovent

pressurizedgas

STEP8:Readingthepressuregaugeateyelevel

STEP7B:Usinganorbitalmotiontospintheballs

aroundinsidethechamber

7

8

9

10