7

5 PRERINSING

Some liquids (e.g. protein-containing solutions and

organic solvents) can leave a lm of liquid on the

insidethewallofthetip;pre-rinsethetiptominimize

any errors that may be related to this phenomenon.

Pre-rinsing consists of aspirating the rst volume

of liquid and then dispensing it back into the same

vessel (or to waste). Subsequent volumes that you

pipette will have levels of accuracy and precision

within specications.

This pre-rinsing operation should be repeated when

a new tip is used.

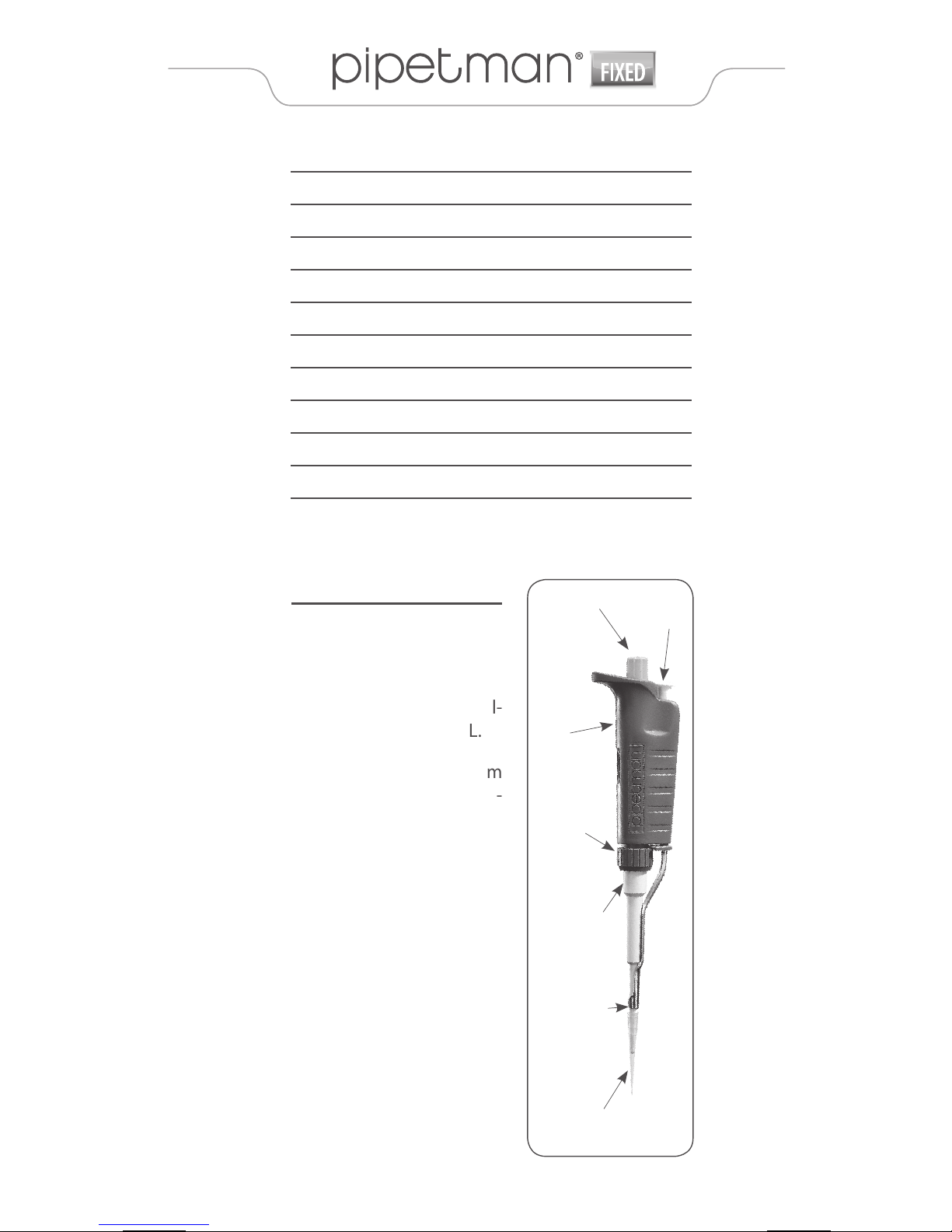

6 PIPETMAN DIAMOND TIPS

PIPETMAN DIAMOND Tips are made to the highest

specications, strict quality control is maintained

throughout the manufacturing process. These tips

are used to calibrate PIPETMAN Fixed, therefore

for optimum performance we recommend using

PIPETMANDIAMONDTipswithyourPIPETMANFixed.

PIPETMAN DIAMOND Tips have the Gilson logo

engraved on their collar, ensuring that you have a

genuine Gilson product. To ensure accuracy and

precision,Gilson'sQualityAssuranceSystemfocuses

on the following critical parameters.

• PIPETMAN DIAMOND Tips are made from pure

polypropylene (virgin, metal-free, to avoid the

possibility of contamination). They are available

sterilizedandwithlters.

• Optimized shape (revised collar for optimum

sealing, thin walls, and ne point), making them

easier to mount, more exible, with no vortexing,

and improved precision.

• PIPETMAN DIAMOND Tips are free from even

microscopic defects, especially at the orice. All

surfaces are smooth and hydrophobic, thereby

avoiding the excessive retention of liquids that

causes poor accuracy and a lack of precision.