Installation

WARNING

FLAMMABLE

OR T

OXIC

V

APOR HAZARD

Provide fresh air ventilation to avoid the

buildup of flammable or toxic vapors. Do

not operate the spray gun unless ventila

-

tion fans are operating. Follow all nation

-

al, state, and local codes regarding air

exhaust velocity requirements.

NOTE:

D

Have the system binder (a collection of manuals

and diagrams in a three-ring binder

, supplied with

the system by Graco) available during installation.

D

Reference numbers and letters in parentheses in

this manual’

s text refer to the numbers and letters

in the illustrations.

D

Be sure all accessories are adequately sized and

pressure-rated to meet the system’s requirements.

D

Connect the fluid and air supply lines as instructed

in this manual and the system binder

.

The following instructions generally presume a stan

-

dard system using pressure tanks to supply the paint

components and solvent. See also

Optional Fluid

Supplies

, below

, for possible variations and their

ef

fect on the instructions.

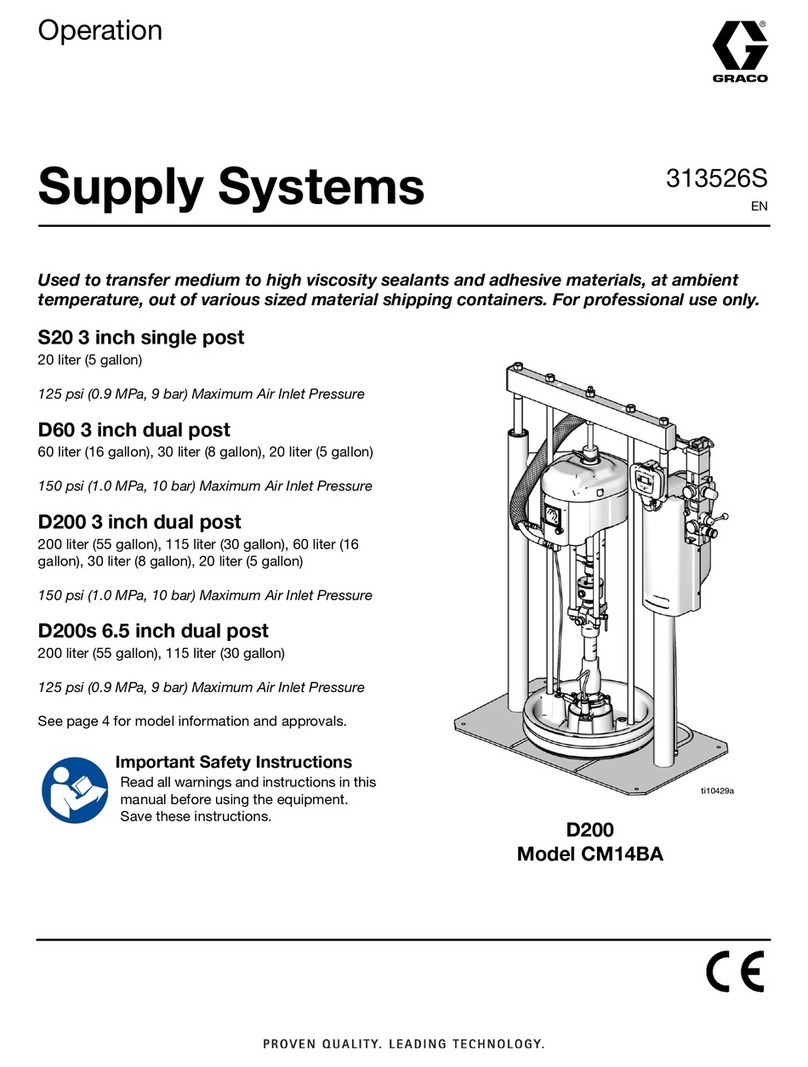

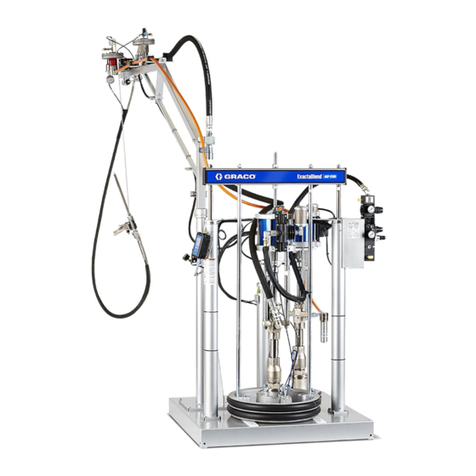

Fluid Supply

The

following installation and operation instructions

generally presume a standard system, using pressure

tanks to supply the paint components and solvent.

The Optional Fluid Supplies

listed below are two

possible variations and their effect on the instructions.

Optional Fluid Supplies

NOTE:

The fluid supply must be free of pressure

spikes, which are commonly caused by a pump stroke

changeover

. If necessary

, install pressure regulators

or a surge tank on the fluid inlets to the mix manifold,

to reduce the fluid supply pressure. Contact Graco for

information on fluid pressure regulators.

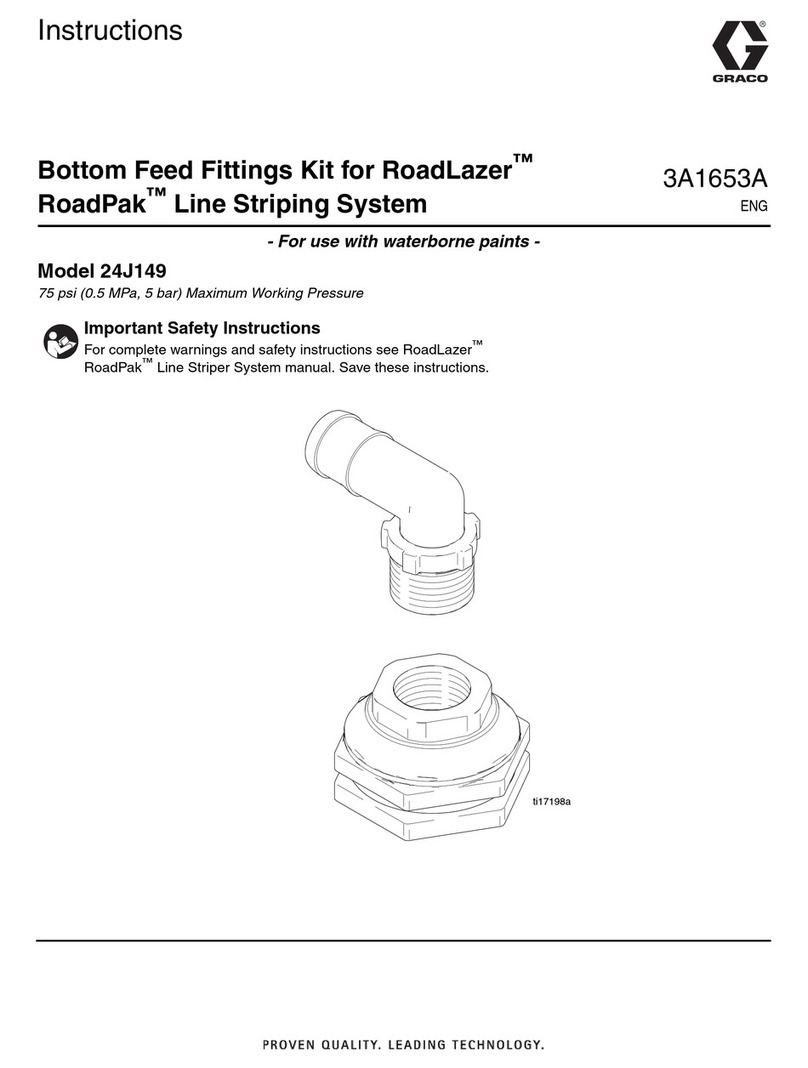

Supplying Fluid Through Circulating Lines

If there is a central paint recirculating line in your shop,

the mix manifold can be connected to it instead of to

pressure tanks. Other than references to the pressure

tanks, operation is the same as described in this man

-

ual.

For maintenance and safety

, you must install a ball

valve between each supply line and the mix manifold.

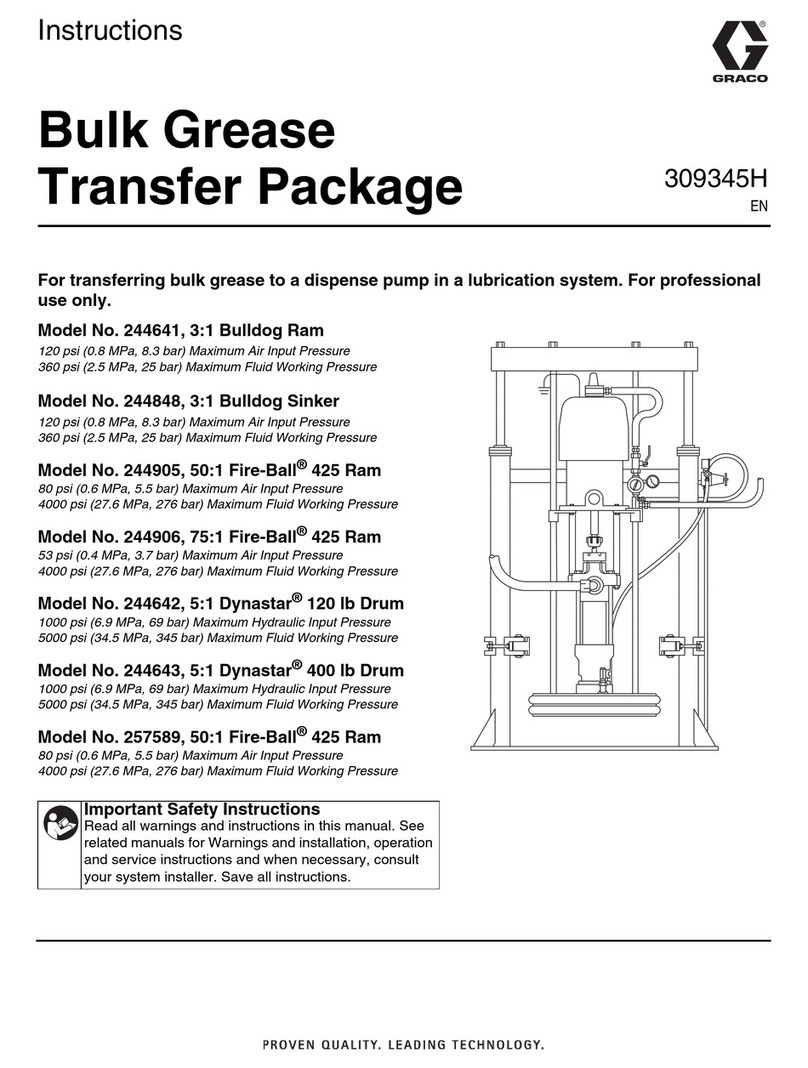

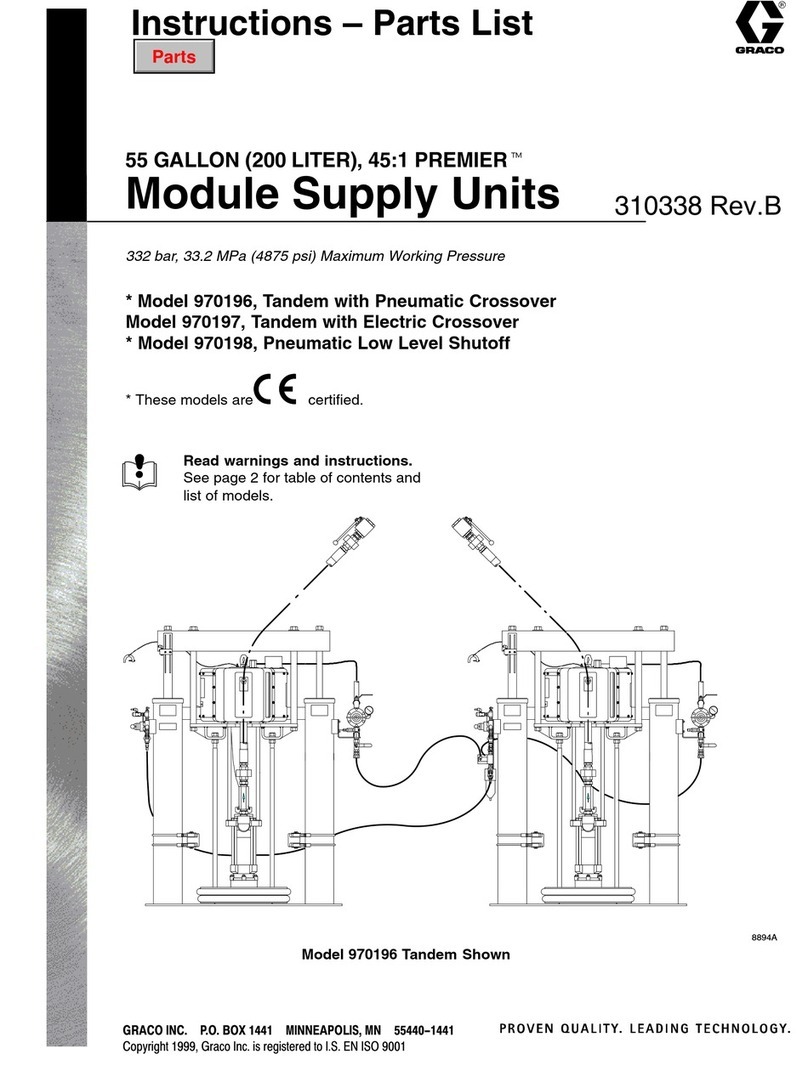

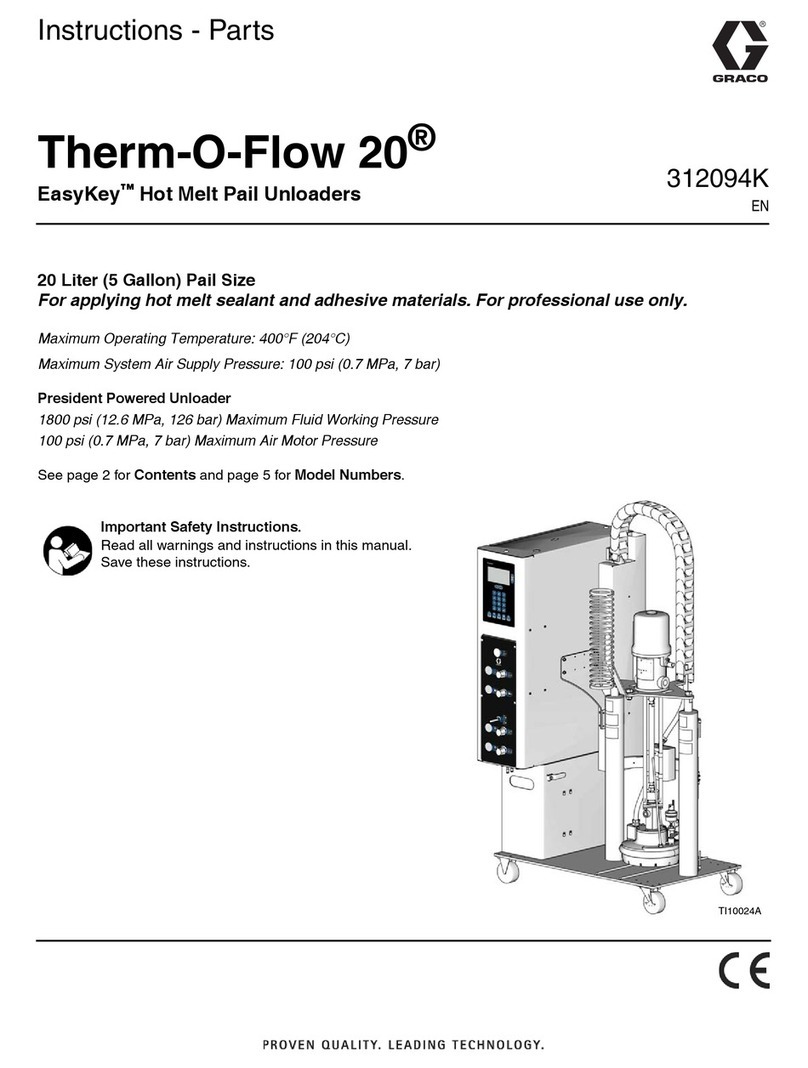

Supplying Fluid Through Pail or Drum Pumps

Instead of pressure tanks, the mix manifold can be

supplied by pail or drum pumps. Operation is the

same, other than references to the pressure tanks.

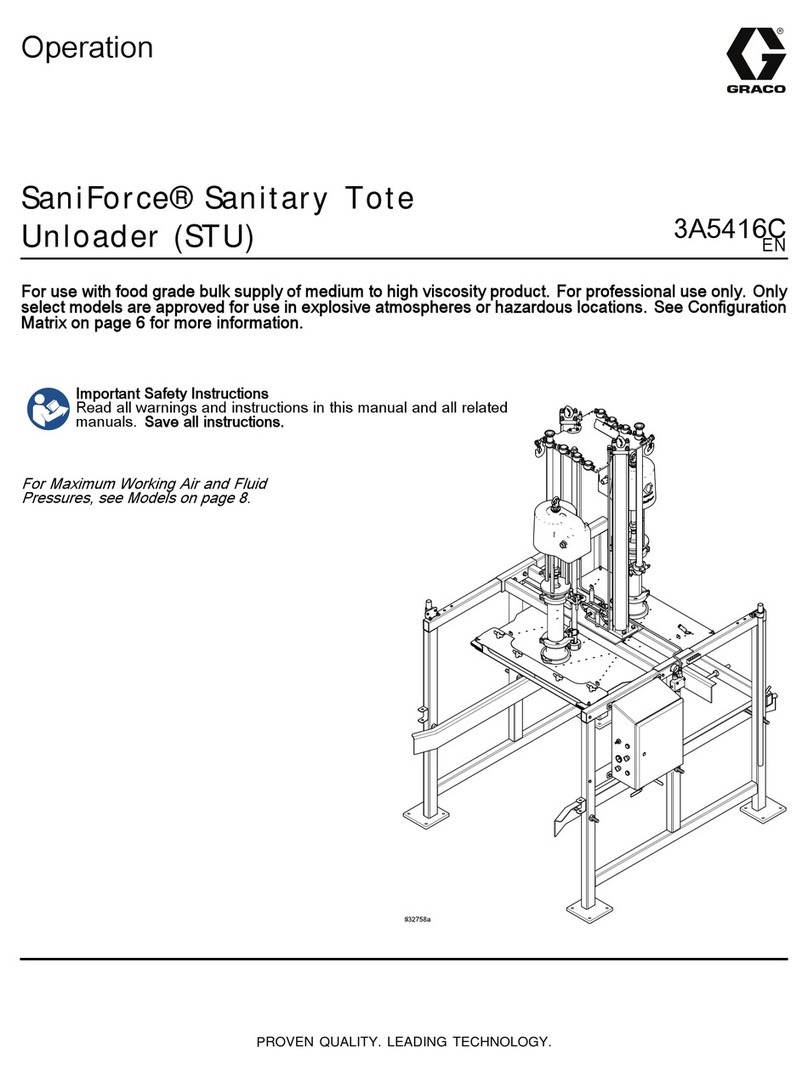

Ground the System

(See Fig. 3)

WARNING

FIRE,

EXPLOSION, AND ELECTRIC

SHOCK HAZARD

T

o reduce the risk of fire, explosion, or

electric shock:

D

The mix manifold must be electrically

connected to a true earth ground; the

ground in the electrical system is not

sufficient.

D

All wires used for grounding must be

10 gauge minimum.

D

Refer to your local code for the requirements for

a “true earth ground” in your area.

D

Also read and follow the warnings on page 2.

NOTE:

A ground wire and clamp, part no 222–01

1, are

available from Graco.

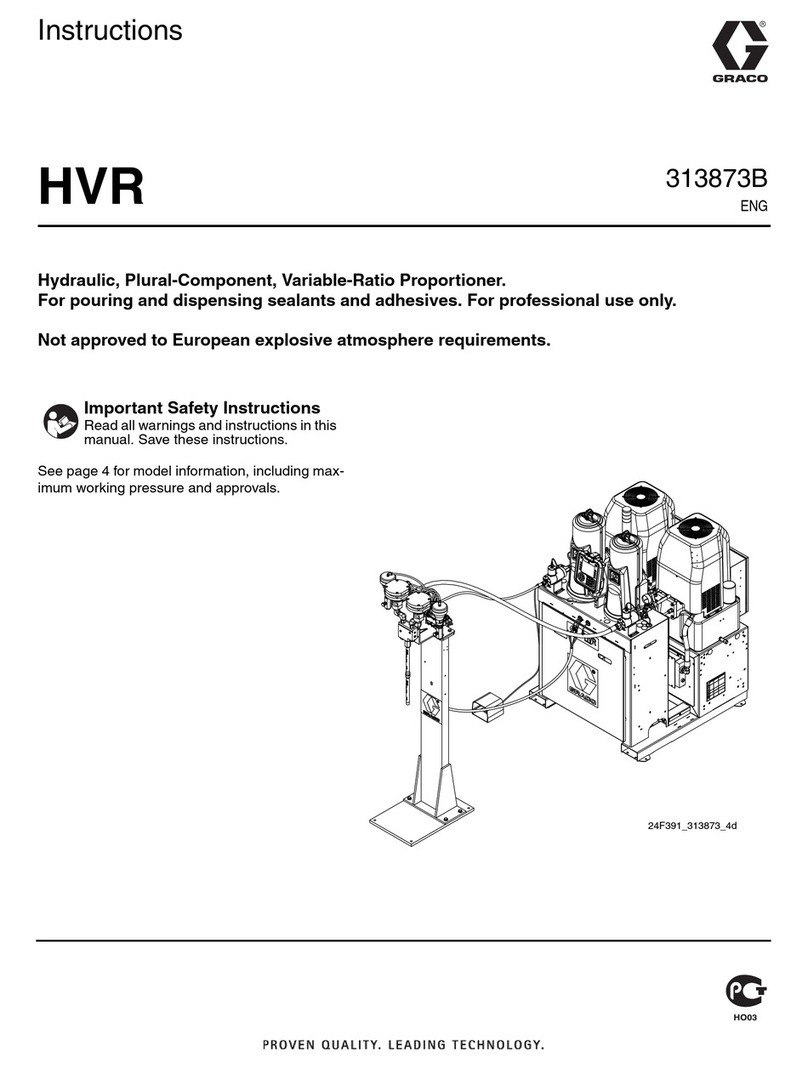

Plural Component Mix Manifold

The mix manifold must be electrically connected to the

same true earth ground point as the controller enclo

-

sure. Dif

ferent ground points may cause current to flow

through the meter cables, causing incorrect signals.

The ground wire can be connected to the mix manifold

or to the mix manifold mounting surface if there is

electrical continuity between the mounting surface and

the mix manifold.

PrecisionMix System: Solenoid Enclosure

Connect a ground wire from the solenoid enclosure’

s

grounding lug to the same point as the mix manifold

mounting surface’

s ground wire.

Controller

Ground the controller as instructed in the controller

manual. The controller enclosure and the mix manifold

must be connected to the same true earth grounding

point.