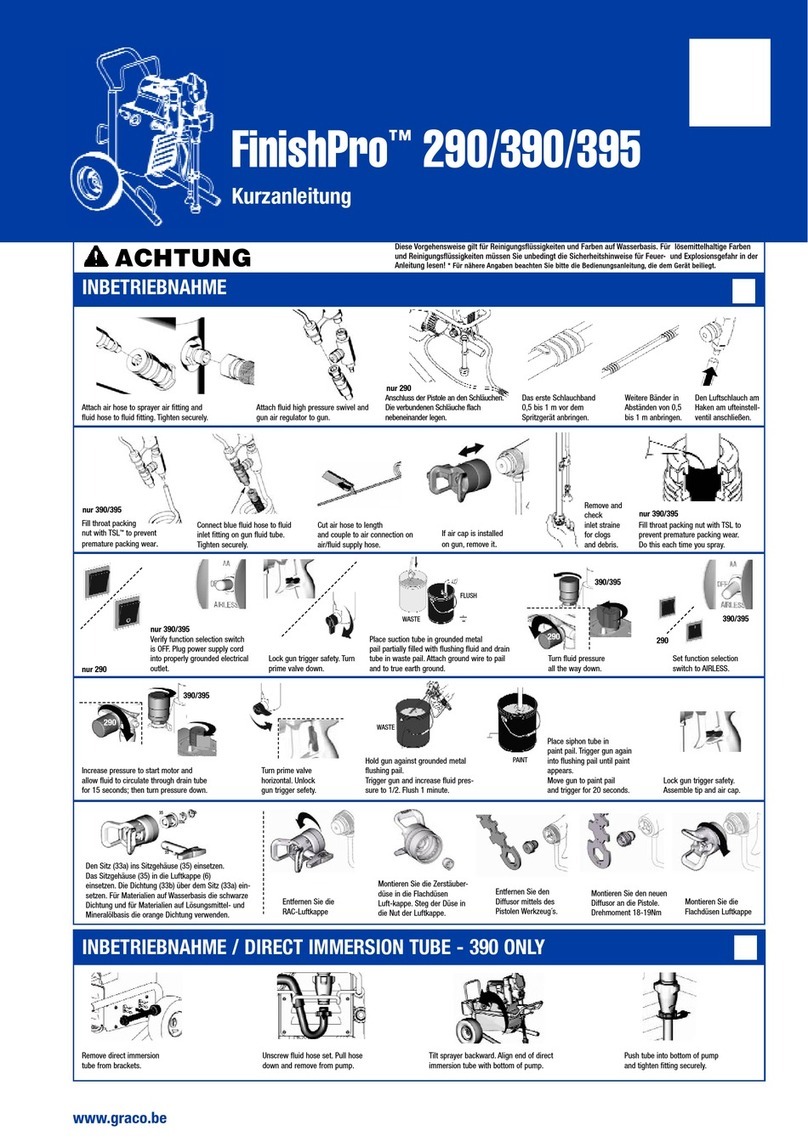

Startup

Pressure Relief Procedure

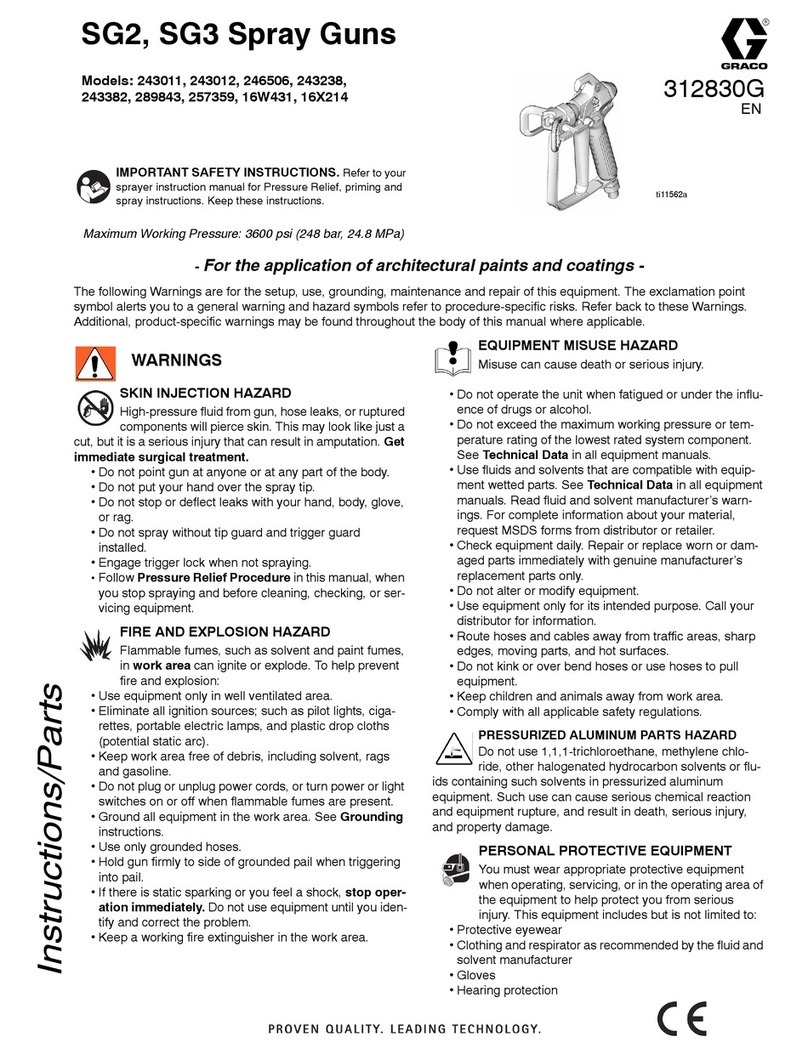

WARNING

INJECTION

HAZARD

The system pressure must be manually

relieved to prevent the system from

starting or spraying accidentally

. Fluid

under high pressure can be injected through the

skin and cause serious injury

. T

o reduce the risk of

an injury from injection, splashing fluid, or moving

parts, follow the

Pressure Relief Procedure

whenever you:

are instructed to relieve the pressure,

stop spraying,

check or service any of the system equipment,

or install or clean the spray tip.

1.

Lock the gun trigger safety

.

2. T

urn the ON/OFF switch to OFF

.

3.

Unplug the power supply cord.

4.

Unlock the trigger safety

. Hold a metal part of the

gun firmly to the side of a grounded metal pail, and

trigger the gun to relieve the pressure.

5.

Lock the gun trigger safety

.

6.

Open the pressure drain valve, having a container

ready to catch the drainage. Leave the valve open

until you are ready to spray again.

If you suspect that the spray tip or hose is completely

clogged, or that pressure has not been fully relieved

after following the steps above,

VER

Y SLOWL

Y

loosen the tip guard retaining nut or hose end coupling

to relieve the pressure gradually

, then loosen com

-

pletely

. Now clear the tip or hose.

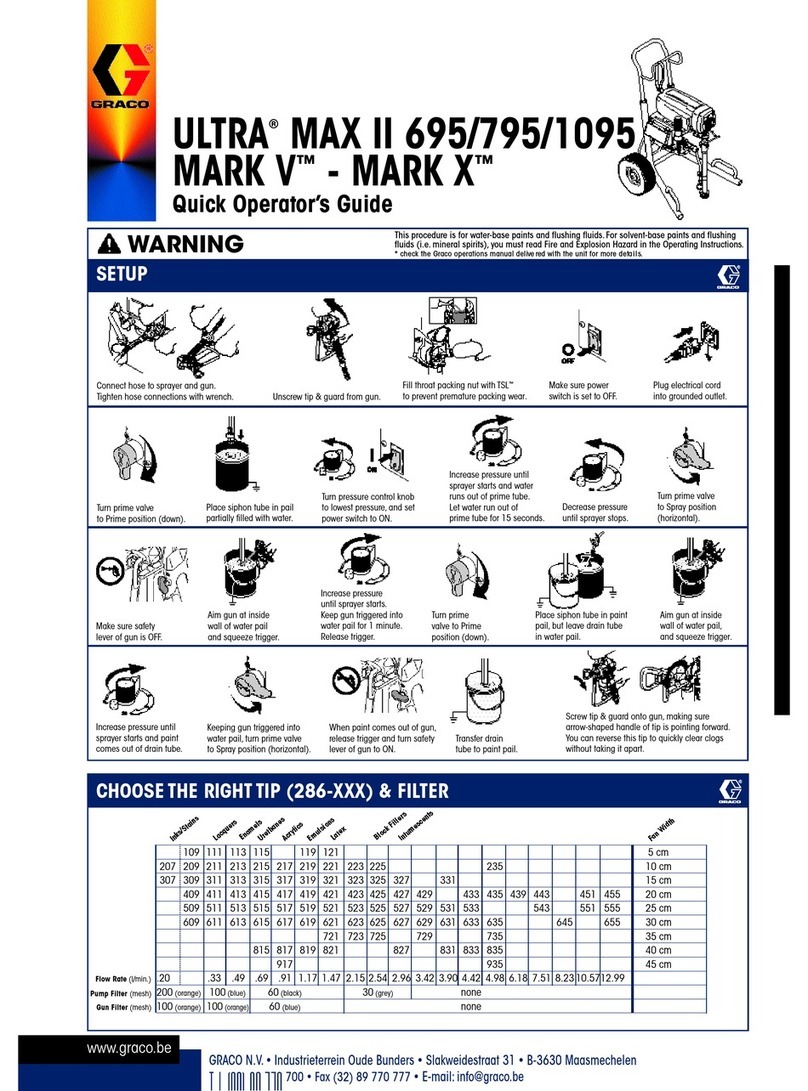

Startup Procedure

Use

this procedure each time you start the sprayer to

help ensure the sprayer is ready to operate and that

you start it safely

.

NOTE:

If this is a first-time startup, flush the sprayer

.

See page 12.

NOTE:

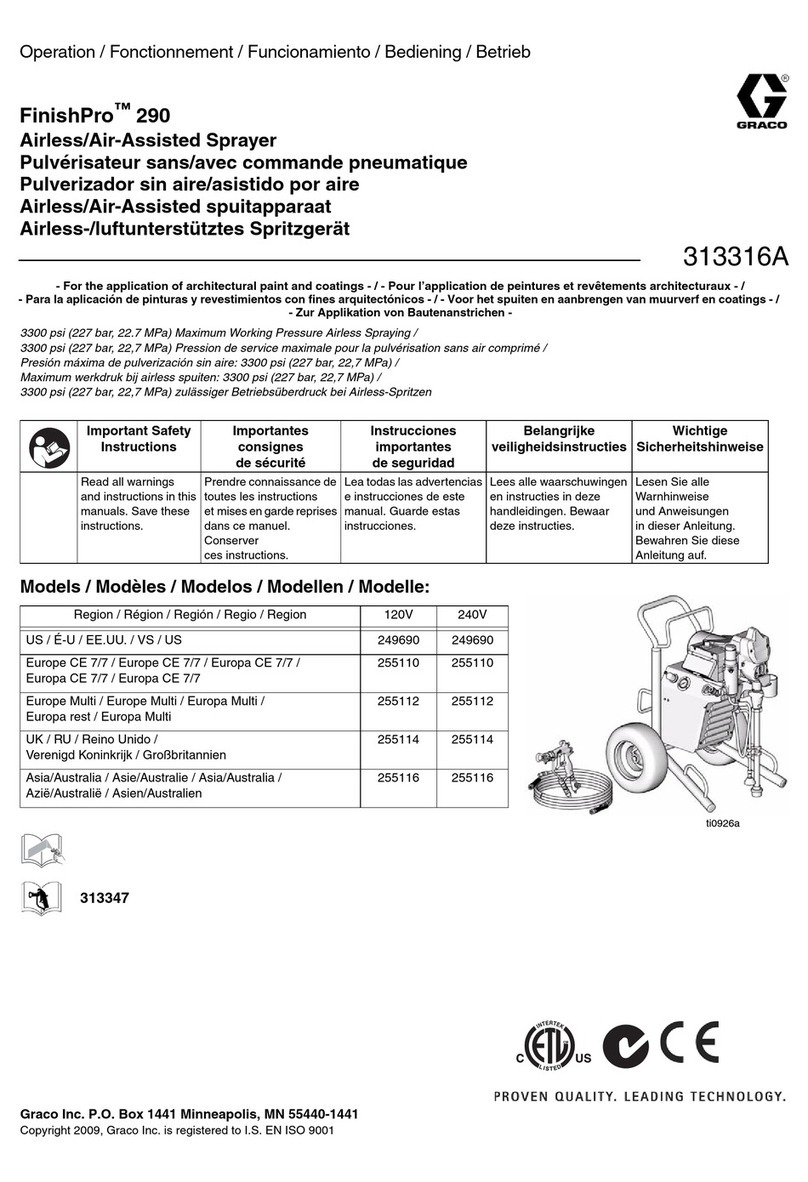

Refer to Fig. 1 and other figures referenced in

the text as you start the sprayer

.

1.

Open the pressure drain valve (42)

.

2. Do not install the spray tip until the pump is

primed.

3. Put the suction hose (32) into the paint

. If you

are pumping from a pail, push the drain hose (33)

down below the top of the pail to avoid splashing

paint wen the drain valve is opened.

4. T

urn the pressure knob (64) to the minimum

setting.

5. Unlock the gun trigger safety

. See Fig. 2, page

7.

CAUTION

T

o reduce the risk of damage to the displacement

pump packings, never run the pump without fluid in

it for more than 30 seconds.

6. T

o prime the pump

, turn the sprayer switch (52)

on. Slowly increase the pressure until the sprayer

starts. When fluid comes from the pressure drain

valve, close the valve.

WARNING

T

o reduce the risk of static sparking and splashing

when flushing, always remove the spray tip from

the gun, and hold a metal part of the gun firmly to

the side of, and aimed into, a grounded metal pail.

See Ref. A in Fig. 6.

Fig. 6 01024

A

7. T

o prime the hose

, lower the pressure to reduce

splashing. Hold a metal part of the gun firmly

against and aimed into a grounded metal pail. See

the

WARNING

above. Hold the trigger open and

slowly increase the pressure until the pump starts.

Keep the gun triggered until all air is forced out of

the system and the fluid flows freely from the gun.

Release the trigger and lock the gun trigger safety

.