308-1

62

INSTRUCTIONS/PARTS

LIST

GRACO

Rev.

A

WARNINGS

and

INSTRUCTIONS.

mls

manual contains

IMPORTANT

READ

AND

RETAIN

FOR

REFERENCE.

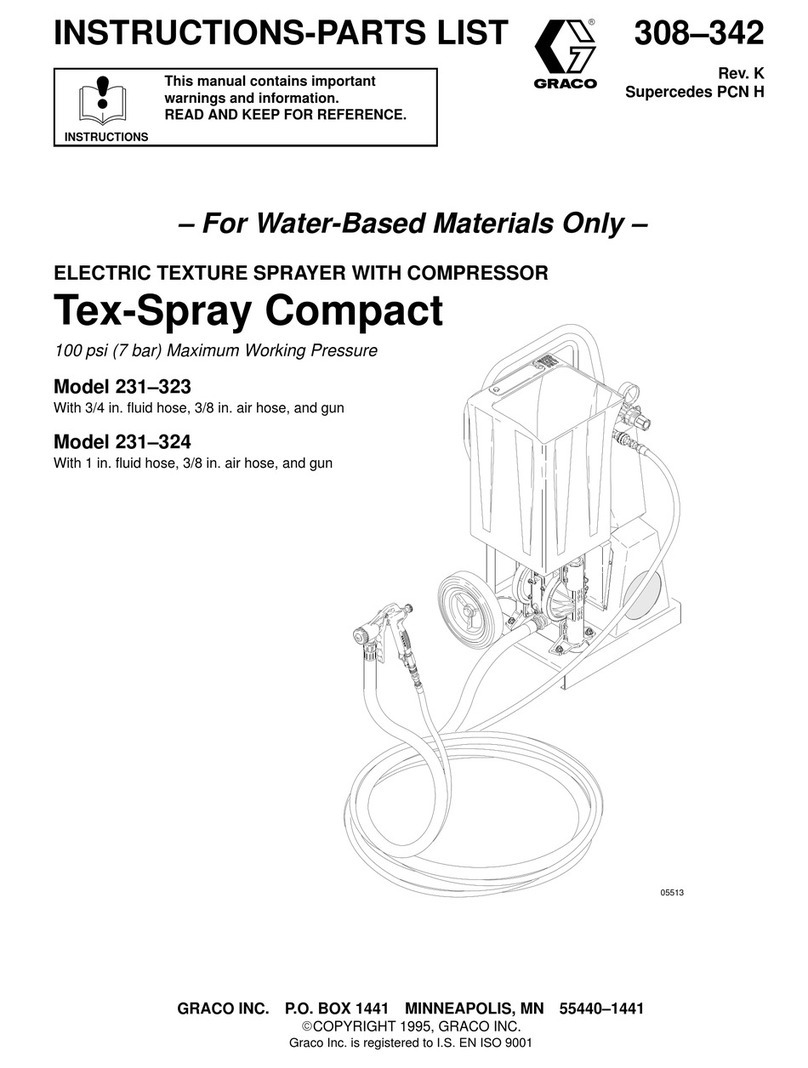

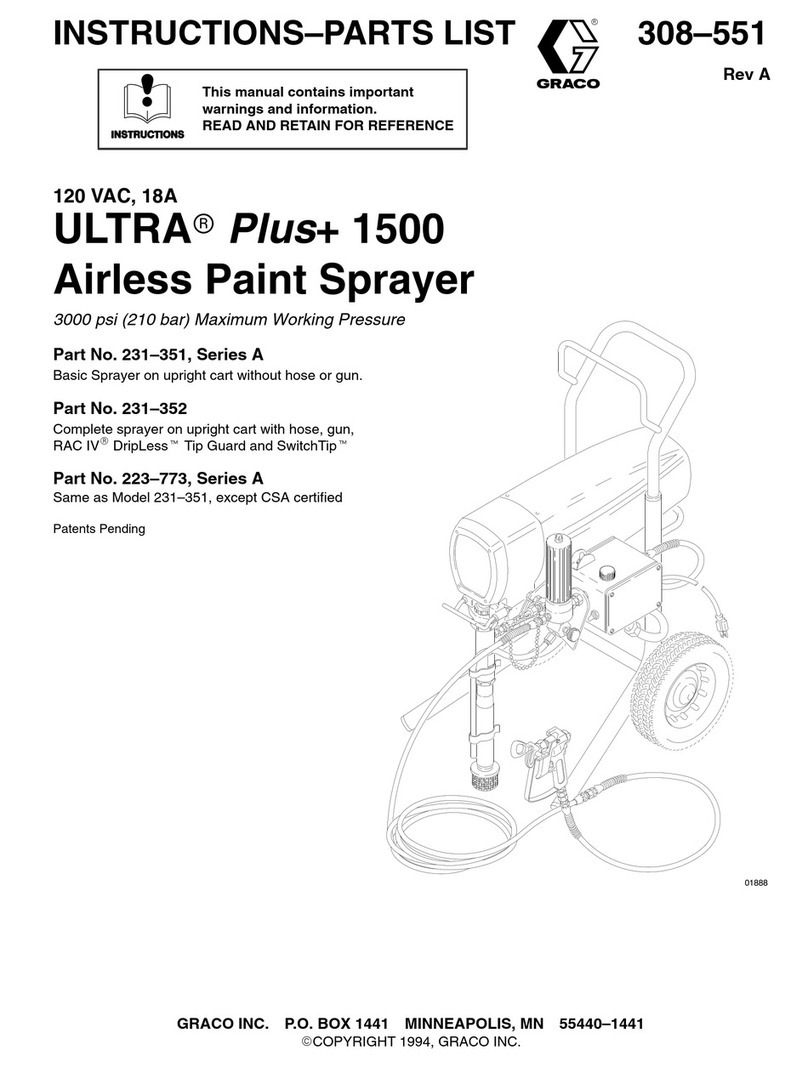

TEXTURE

SPRAY

GUN

100

psi

(7

bar)

MAXIMUM

AIR AND FLUID WORKING

PRESSURE

Model

224-722,

Series

A

PressureRelief Procedure

To reduce the risk of seriousbodily injury, including

electric shock and splashingfluid inttie eyes, fol-

lowthis procedurewhenever you stop spraying.

2.Trigger the gun.

1.

Shut

off

thepump orsprayer.

3.

Openthegunairvalve.

4.

Disconnectthepowersource.

Grounding

To

reduce the risk of electric shock, proper electri-

cal grounding is essential. See your separate

your local electricalcodesfor detailed grounding

pump

or

sprayer instruction manual, and consult

instructions.

Worklng Pressure

To reduce the risk of component rupture and seri-

ous bodily injury, never exceed

700

psi

(7

bar)

AIR

OR

FLUID

WORKING

PRESSURE

to

this gun.

Do

not exceed the maximum working pressure of any

other component In the system.

Fluid

and Solvent Compatlblllty

ride, other halogenated hydrocarbon solvents or

Do

not use

1,l

,1-trichloroethane, methylene chlo-

which contains aluminum and/or zinc parts. Such

fluids containing such solvents in this equipment,

with theposslblllty of explosion,whicti could

use couldresult in a serious chemical reaction,

cause death, seriousbodily injury andlor substan-

tial properly damage.

flow knob

(18)

so

only

1

or

2

threads are visible.

Ful-

mestandard aun adiustmentlsto adjust the material

ly open the airflowvalve (24) byturning it as.far as

possibleto

+.

valve (423)

Is

open. Close the valvetostoo theair.

If

Air

bleedsfrom the aun nozzle whenever the gun air

desired. Other.&, it can stay open except during

priming.

For continuous soravir\g.use thetrigger bail

(1)

to

holdthe trigger opento reduce fatigue.

m.

squeeze the trigger slowly

to

the fully trig-

To orevent material surae at the beainnina

of

a sora

gered positionwhilemovingthegunquickly.

Air

Inlet

Adiustina thewravoattem requires testingto bal-

ance the ourno pressure and the air to

the

aun. and

1/4

npsm

M31

usingthe'righitip size.

2.

Adjust the pumppressure

until

the material

1.

Test the spray pattern on cardboard. Hold

the

stream Isabout

8

In.

(203

mm) long.

gun

16-30

in. (457-762 mm) from the surface.

Use this spraying distanceformost applications.

3.

Adjust the pump and the gun air flow valve

(24)

to achieve a uniform, round spray pattern.

".

GRACOINC.

P.O.

BOX.1441

MINNEAPOLIS, MN

55440-1441

@COPYRIGHT

1991,

GRACO INC.