6 309442E

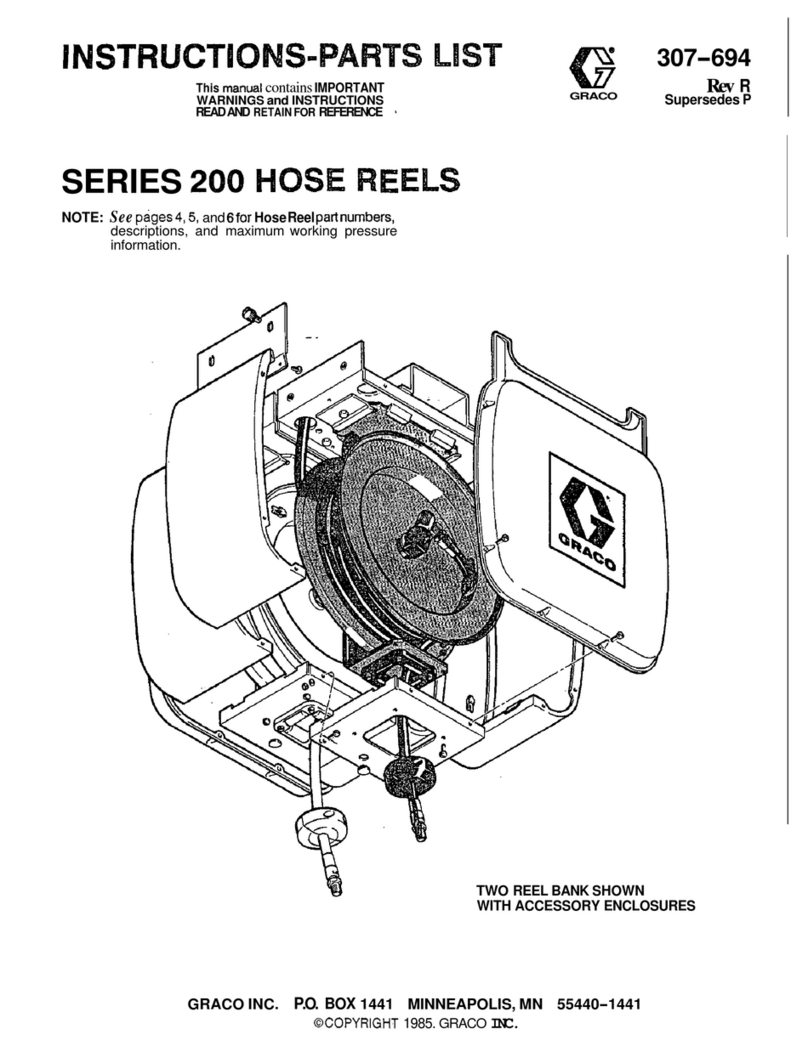

Installation–Hose

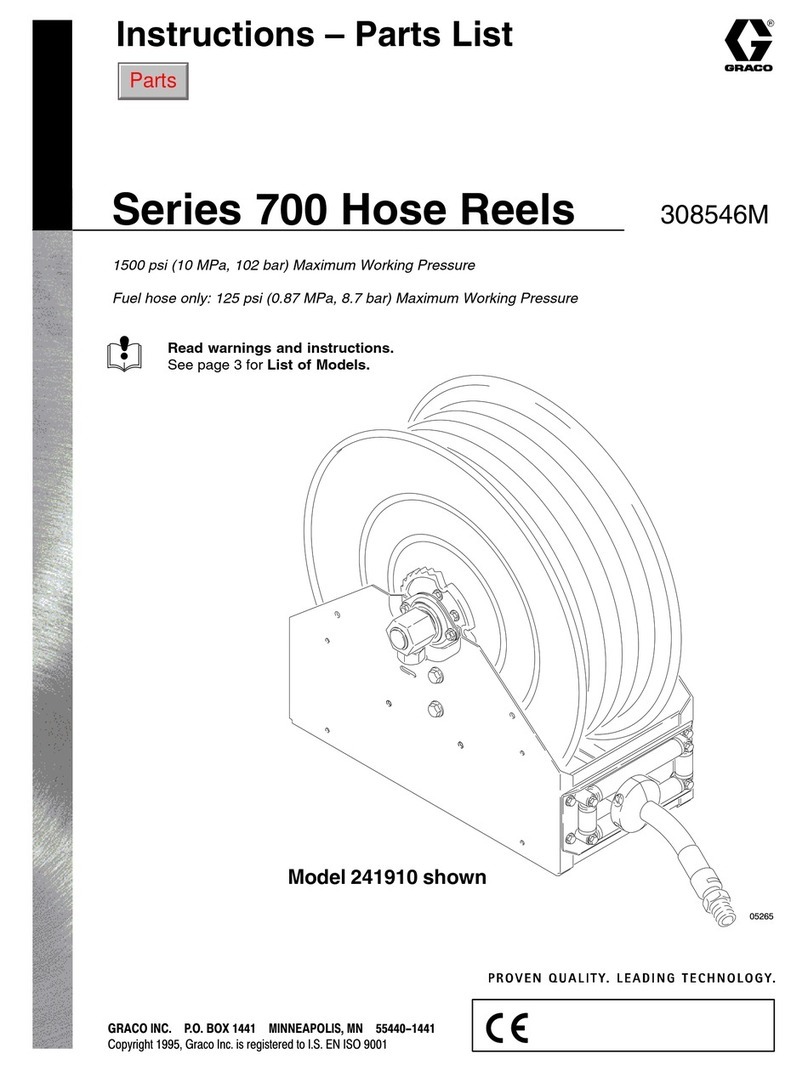

To install a hose on a hose reel with the proper amount

of spring tension, follow these steps:

WARNING

Improper grounding can cause a hazardous

condition and may result in fire or explosion and

serious injury. The hoses installed with this reel

must be electrically conductive.

WARNING

Always wear heavy, non-slippery gloves when

adjusting the spring tension to protect your hands

from being cut on the hose reel.

1. Clamp the hose reel to a flat surface.

2. Place a piece of tape on the side of the reel flange

as a visual reference point for counting reel rota-

tions.

3. Unlatch the reel drum, and allow it to slowly rotate

until all spring tension has been released. Then

rotate the reel in the direction of the arrow shown

in Fig. 2 to achieve the proper amount of spring

tension for the hose you are installing, approxi-

mately 14–15 turns.

NOTE: Release the reel only at points where it is

securely latched.

4. Attach a C-clamp to the reel flange, as shown in

Fig. 2, to help prevent the reel from unintentionally

becoming unlatched and spinning freely.

WARNING

Never allow the reel to spin freely. Doing so

causes the hose to spin out of control, which could

cause serious injury if you are hit by the hose.

5. Uncoil and extend the new hose, and loosely

install the hose stop (25) near the outlet end of the

hose.

6. Attach the other end of the new hose to the

90-degree elbow.

7. Remove the C-clamp from the reel flange.

8. Pull the hose firmly enough to release the latch,

then slowly allow the hose to retract.

9. Ensure that the hose can be pulled out all the way

and that it fully retracts. If it does not pull out or

retract properly, see Adjusting Spring Tension

on page 7.

10. Position the hose stop (25) so that the hose ex-

tends far enough for all operators to reach the

dispensing valve.

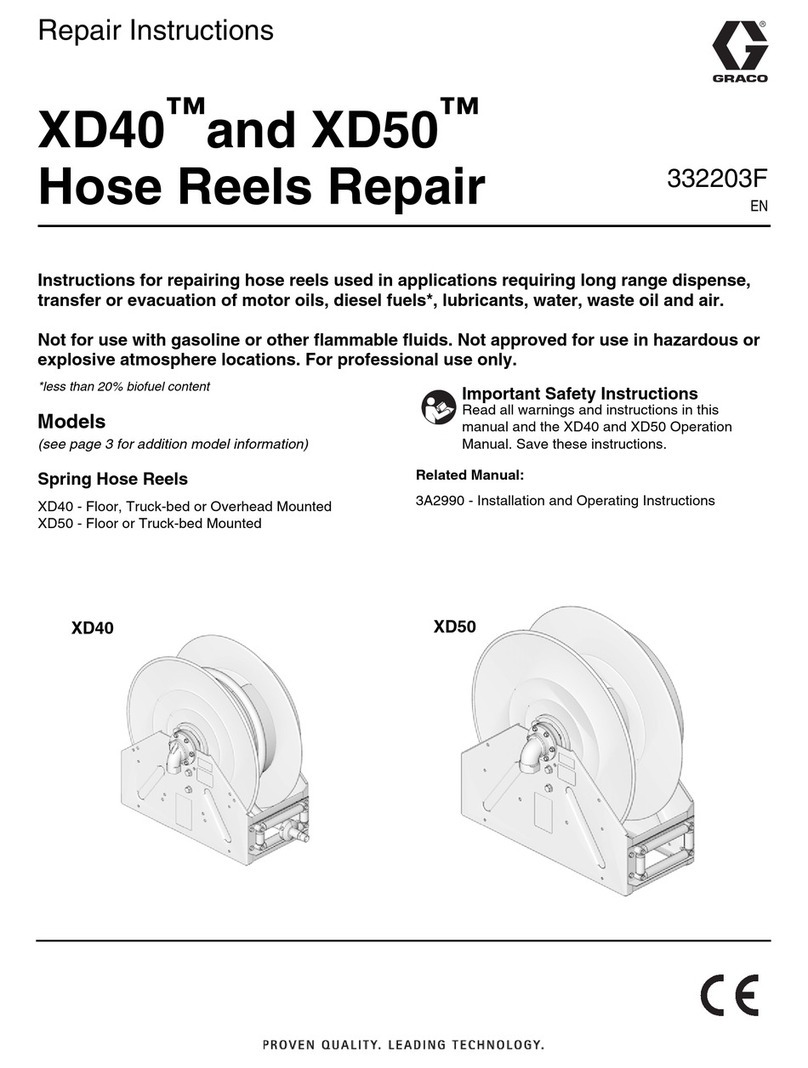

Fig. 2

25

C-clamp

ti1625d