Installation

3A2592A 9

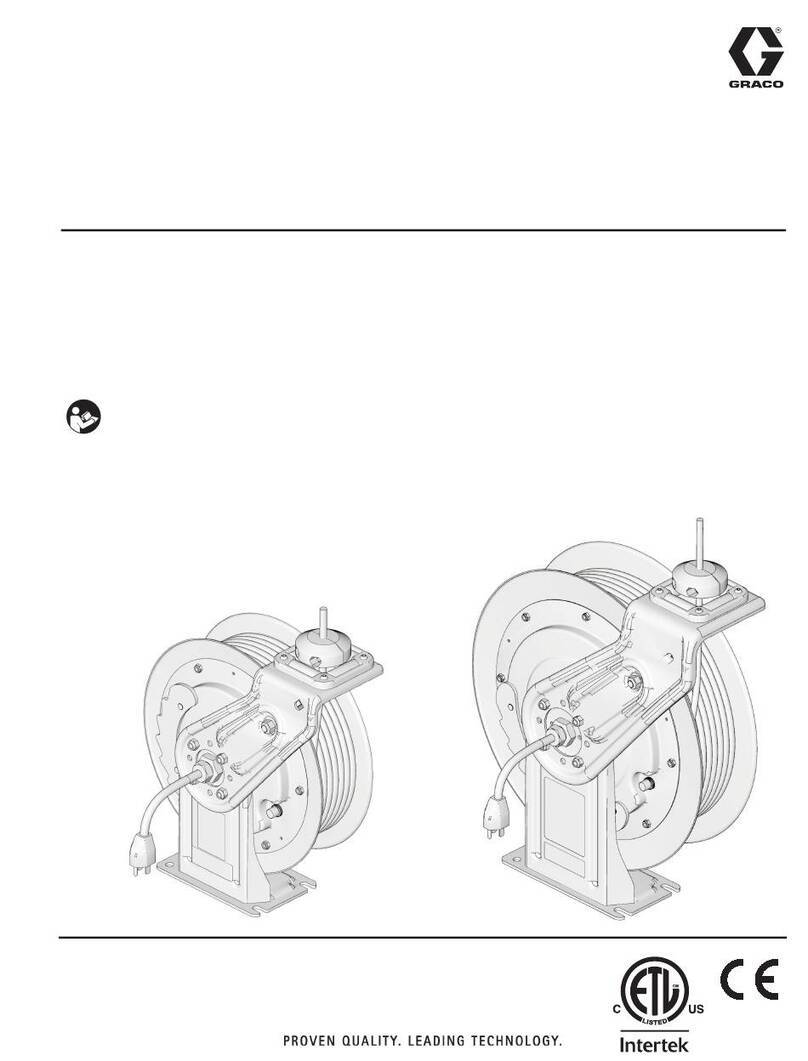

Mounting

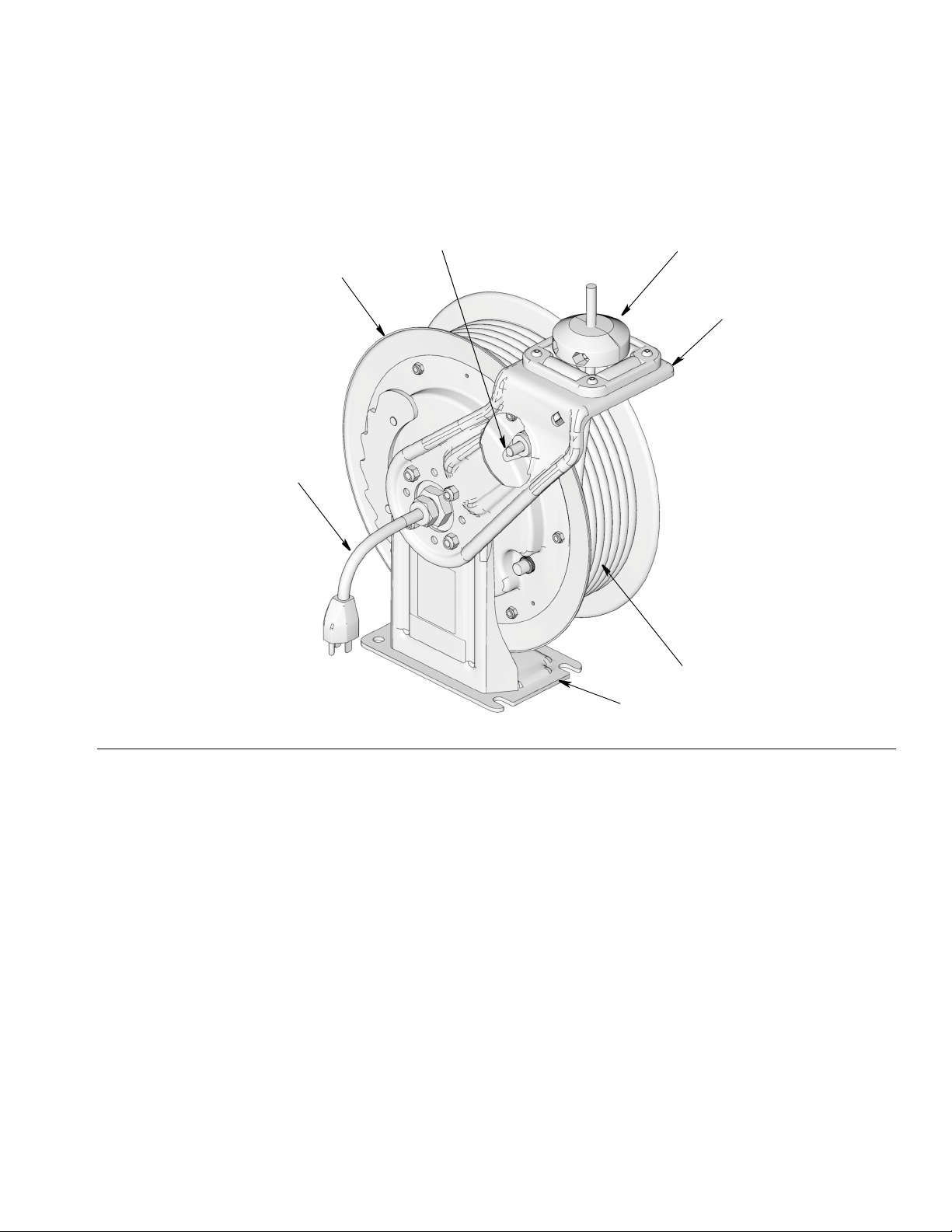

Wall/Ceiling Mounting with Plate

NOTE: For wall and ceiling installations, the user must

provide four mounting bolts and four washers (A) (FIG.

5) that are strong enough to support the weight of the

cord reel, cord and accessories. See Technical Data,

page 26 for the cord reels weights without accessories.

*Discard the extra 4 screws (101) and washers (102)

provided in the Plate Mounting Kit. This hardware is not

strong enough to support the cord reel, cord and acces-

sories and should only be used for open channel mount-

ing applications.

1. Ceiling Mount Only: Position cord reel so the reel

base is facing up.

2. Check pawl to make sure it is not wedged (FIG. 4).

(Also see General Installation Information page 8.)

3. Use the reel base (FIG. 5 - 105) to lay out the posi-

tion of the mounting holes before you drill

NOTE: For easier installation, mount the base plate

(105) to the wall first (FIG. 5).

4. Drill mounting holes. Mount base plate (105) to wall

using 4, user supplied mounting bolts (A) that are

strong enough to support the weight of the cord reel,

cord and accessories. Tighten bolts securely.

5. Slide cord reel onto the base plate (105) and install

the hold-down plate (104), washer (102) and screw

(101). Tighten the screw firmly (FIG. 5).

The electric cord reel is heavy and may be difficult to

mount without assistance. (See Technical Data, page

26 for weights of cord reel assemblies.) To reduce the

risk for injury:

• Be sure the mounting surface and bolts are

strong enough to support the cord reel’s weight

and stress caused by hard pulls on the accessory

cord.

• When you are mounting a cord reel overhead,

always use a lift truck and be sure it is secure

before lowering the lift truck.

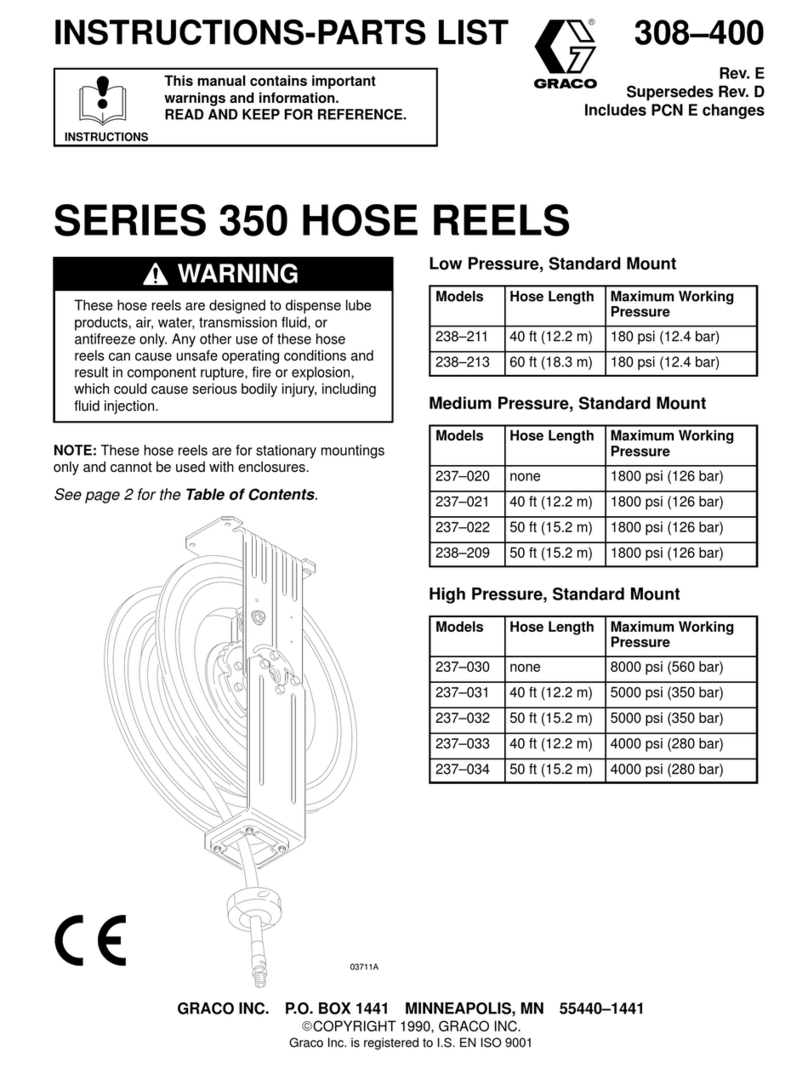

Plate Mounting Kits SD10 SD5

FN Description 24H193 24N686

101 SCREW, 3/8” x 16 x 5/8” 1* 1*

102 WASHER, lock,3/8” 1* 1*

104 PLATE, hold down 1 1

105 BASE, plate 1 1

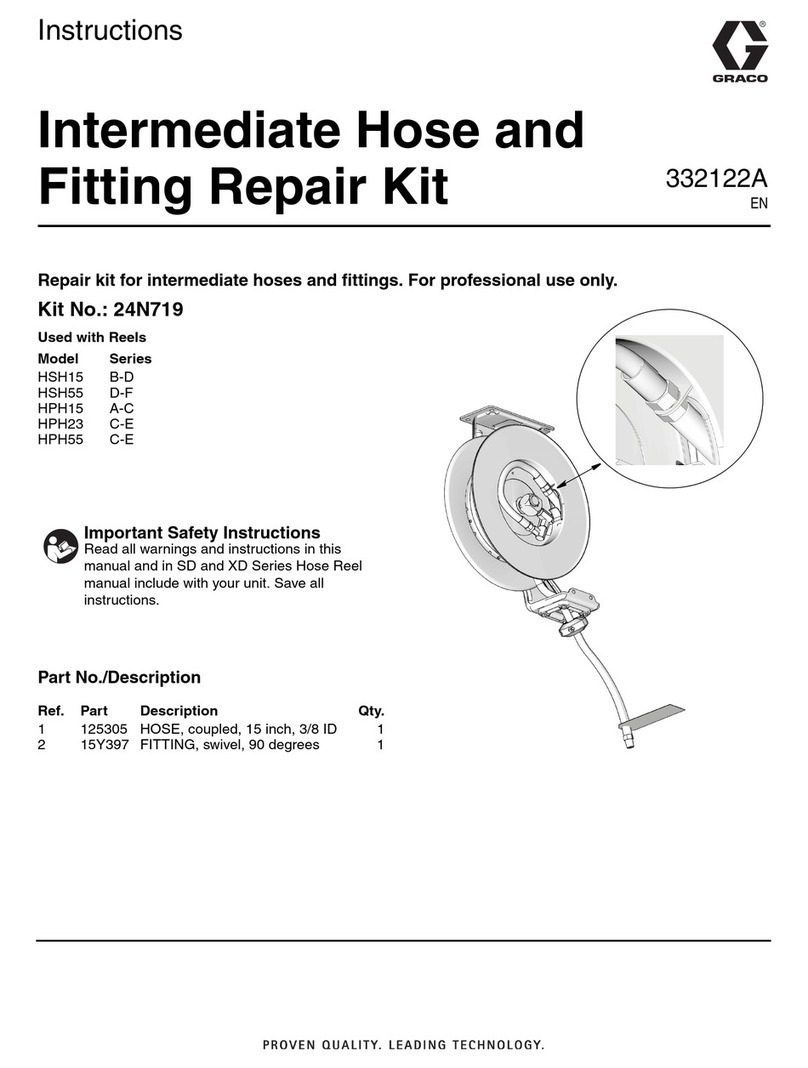

FIG. 4

FIG. 5