Fluidemittedunderhighpressurehomleaksorrupturedcompo

-

nentscanpenetratetheskinandcauseextremelyseriousbodily

injury,inciudingtheneedfor amputation.AIs0,fluidinjectedinto

or splashed intothe eyes cancause seriousdamage.

The

MMMUM

WORKiNG

PRESSURE

Of

your hose reelassem-

System Pressure

biy

isdetermined

by

thelowest

-

ratedcomponentintheassem

-

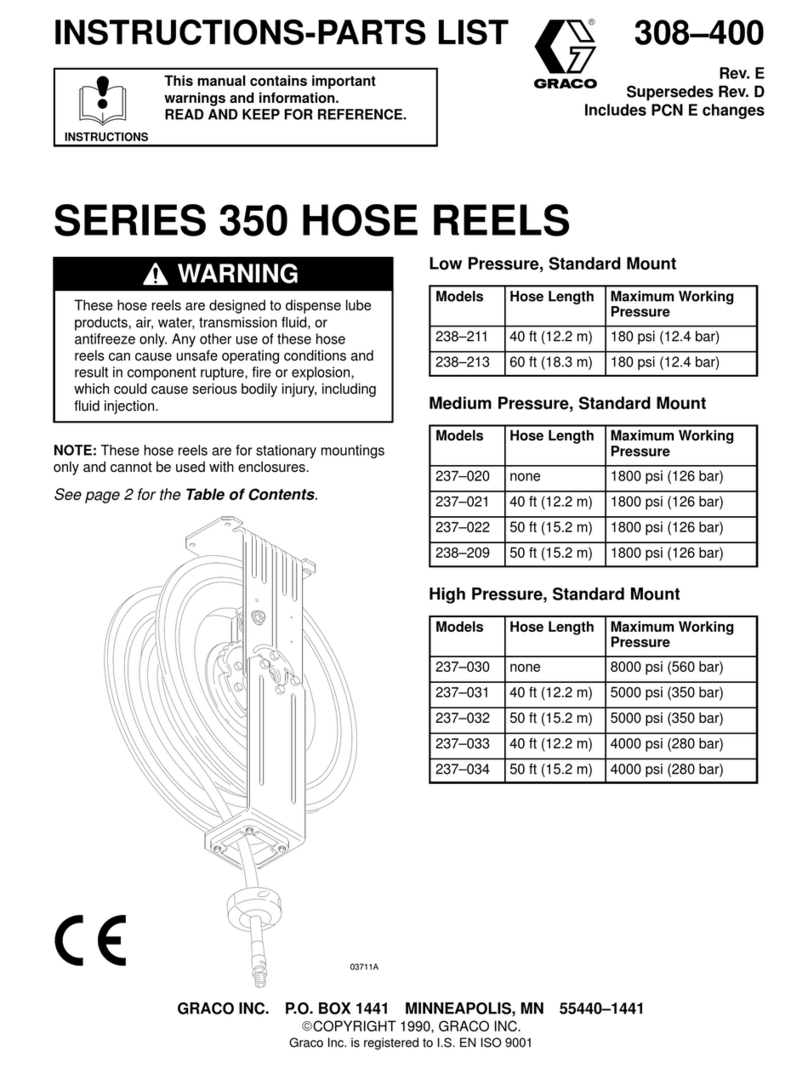

bly. The HOSE REEL MODEL charts on pages

4

to

6

give the

maximumworkingpressureoftheassemblieslistedthere.

If

you

are addingasewice hoseand dispensingvalve to a bare hose

reel,

be

sure you know the maximum working pressureof all

components1

To reducethe risk of serious bodily injury, includingfluid

Pressure Rellef Procedure

from movingparts.alwaysfollowthisprocedurewhenev-

injection. splashing inthe eyes or

on

the skin, or injury

er you shut

off

the pump,andbeforeinspecting,remov

-

ing,cleaningor repairingany partof the pumporsystem.

2.

Closethe supply pump'sbleed

-

type masterair valve

1.

Closethe supply pump'sair regulator.

3.

Open the dispensing valve until pressure is fully

(requiredinpneumaticsystems).

If

yoususpect the dispensingvalve, extension or grease

relieved.

fitting

coupierisdogged, or that pressurehasnotbeen

fully relievedafter foiiowing all the steps above, VERY

SLOWLY lwsenthe couoier or hose end CouDiina and

allow pressureto be relievedgradually,then

ibs&

the

part completely. Now clear the clog.

Do

not modifyany partof the dispensingvalve. Onlyuseexten-

DispensingValve Safety

siansandgreasefittingcouplerswhicharedesignedforusewith

yourdispensingvalve. Modifyingpartscancauseamalfunction

and result in serious bodilyinjury.

Flexible Extension

Safety

extensionyou are using. Never exceedthat pressure,even

if

Be

sureyouknowthe maximumworking pressureof the flexible

your dispensingvalve and/or pump

is

ratedfor higher working

pressures.

..

Never use a low pressure, flexibleextension,designedfor low

pressuredispensingvalves or hand

-

poweredlubricatingequip

ment,

on

a high

-

pressuredispensingvalve.

Neverattemptto force the lubricantinto

a

fitting1

If

thelubricant

isnotflowing, STOP DISPENSING IMMEDIATELY.

The

fitting

may be clogged. Forcing lubricant may cause excessive back

pressureintheflexibieextension,whichcouidcauseittoNpture

and result in serious bodily injury, including

fluid

injectionand

eye injury.

Grease FittingCoupler Safety

Use

extreme caution when cleaningor changing grease fitting

couplers.

if

the coupler clogs while dispensing, STOP

DIS

-

PENSING IMMEDIATELY.

Follow

the Pressure Relief Proce-

builduparound the coupler until pressure isfully relieved.

dure

,

at left.Thenremovethecouplertocleanit.Neverwipe

off

GeneralSafety

Checkthe operationofallequipmentsafetydevicesbeforeeach

use.

NEVER pointthe dispensingvalve at anyoneor any

parl

of

the

body.

NEVER put your handor fingersover the greasefittingcoupler.

NEVER alter or modifyany part of this dispensing equipment;

doing

so

couldcause

it

to malfunction.

CHECK

all dispensingequipment regularly. Repair or replace

worn or damagedparts immediately.

NEVER

try

to stop or deflect leaks

with

your handor body,

Medical

Treatment

...

-

-.

-

-.

.

.

-

-

..

.

.

-..

.

If

any fluid appears to penetrateyour skin, get EMERGENCY

.

MEDICAL CARE AT ONCE.

DO

NOT TREAT AS A SIMPLE

CUT1

Tell

thedoctor exactly what fluidwas injected.

Note

to

Physician: injectionintothe skin isa traumatic

injuw

It

isimportanttolreat the injurysurgically

as

soon

as

possl-

ble.DonotdeiaytreatmenttoresearchtoxicityToxicityisacon-

cernwithsome exotic coatingsinjecteddirectlyintothe blood

stream. Consultationwith a plastic surgeon or reconstructive

handsurgeonmaybeadvisable.

USE

EXTREME CAUTIONWHEN HANDLINGTHE SPRING!

Thespring, whichislocatedbehindthe flange, isALWAYSunder

greattension andcouldbepropelledfrom the lowerflange

with

TO reduce the risk of serious bodily injury when replacingthe

enoughforcetocauseserious bodily injury.

spring, useextremecautionwhen removingthetop reelflange.

flangeto exposethe spring.

Be sure the reel

is

laying flat, and then carefully lift

up

on

the

ALWAYS use lockingpliersto compress and holdseveral row

of the spring together when removing and when installing a

spring. See Fig

1.

Beforedisposingofthespring,carefullyanachaminimumoftwo

hoseclamps aroundthe keeper andspring bandsas shownin

Fig

2.

HOSE

Fig

2

CLAMP

307

-

694

3