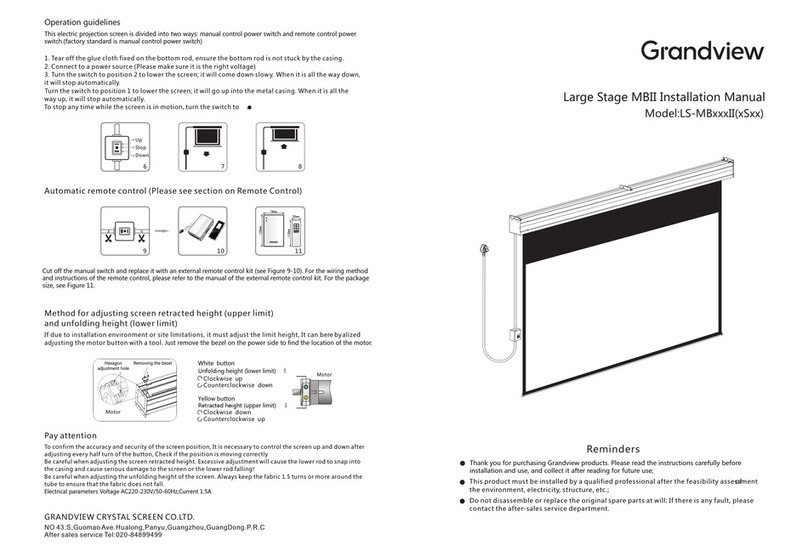

7

Externd IR sensor

Automatic Trigger Control Description

3.You can remove the 12V trigger wire if there is no need.

1.Insert one end of trigger into the trigger jack at left side of screen's end cap TRIG (Figure 22),, and insert another

end into 12V output hole.

2.When the projector is running, screen fabric will go down automatically; when the projector is closed, screen fabric

will retreat automatically.

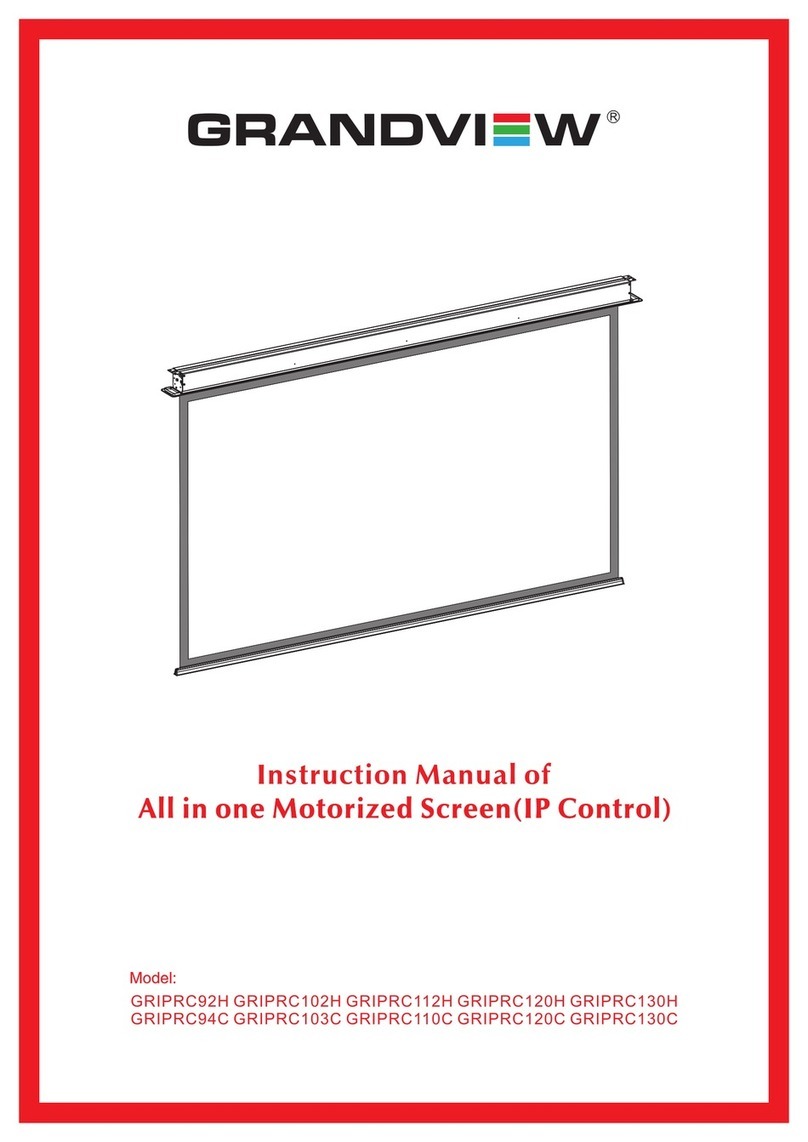

External Controls (Central Control or RS232, Grandview Wall Switch) Function

Plug one side of the signal cord into the computer output jack at left side of the screen's end cap, the other side of

the singal cord to the Central Control jack, RS232 or Grandview Wall Switch (Figure 41-42), and then you can

control the up/stop/down of the screen via central control or computer.

IR Remote Control Function

1.When nothing blocks the sight of IR window, you can use the controller to control the screen (Figure43).

2.For hidden installation or IR window is blocked by something, please take out the External IR Receiver and plug

its head to the revelant hole, and then fix it at the position where IR signal is available. (Figure 44)

Figure 41 Figure 42

Figure 43 Figure 44

Figure 39 Figure 40 4

A

12

Figure 13

Figure 14 Figure 15

Figure 16 Figure 17

Figure 18

4.After completing steps2 and 3,check to seewhether the wallbracket is securelyfixed onto thehousing

of the screenbefore hanging. Hangscreen as shownbelow. (figure18)

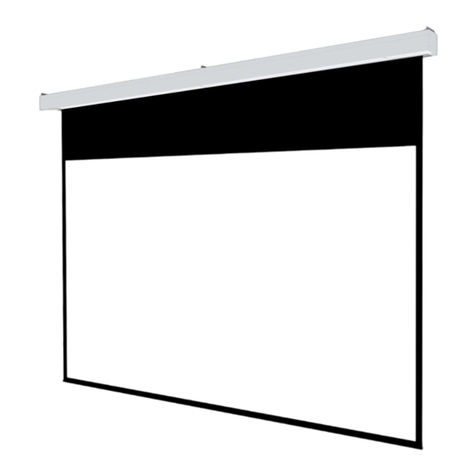

Ceiling Hang Installation

Choose tapping screwswith hangers (orother screws withhangers, not provided)according to your

ceiling material. 5x 40mm forwood ceilings andtapping screws forconcrete ceilings arerecommended.

1.Drill two identicalholes with anelectrical drill andensure it ishorizontal with the

Wall. Fasten hangers(not provided) intothe ceiling (figure13).

2.Use the M5x 10 screwsprovided in theaccessory package tofix the ceilinghanger into thewall bracket.

Ensure the tighteningscrews on thewall bracket aretightened and secure.(figure 14-15)

3.After inserting theceiling hanger,ensure the grooveson the casehousing match upwith the mounting

bracket. To secure thecase housing intothe brackets, tightenthe locking screws.(figure 16-17)