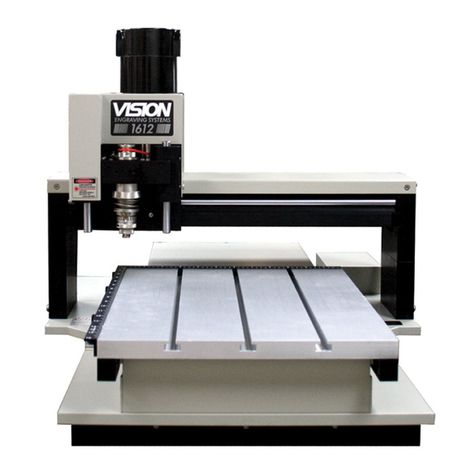

M20 PIX Machine - Electronic Engraving machine . 4 First Contact

Information about regulations

Conformity standards

This hardware was designed and build in conformity with the relevant EC marking and EEC directives :

• "Machine Security" Directive 98/37/EEC (22/06/98).

• "Electromagnetic compatibility" Directive 2004/108/EC

• "Low Voltage" Directive 2006/95/EC

Themodicationortransformationofthisequipment,theadaptationandinstallationof

accessoriesnotrecommendedbyGRAVOTECHMARKINGSAS,theinstallationofthisequi-

pmentinamanufacturingprocess,thepilotingbyarobot,theconnectiontoanexternal

automaton,modifythecharacteristicsofthismaterialandcanmakeitnotcompliantwith

theEuropeanDirectivesitissubjected.Thesemodicationsvoidstheresponsibilityofthe

manufacturer.

Inthiscase,thepersonwhotsthemachineandtheequipmentisresponsiblefortheEC

complianceofthenalworkstation.

Electricalsecurity

This hardware complies with standards EN 60204-1 and EN 60950-1, which also refer to the LASER system safety stan-

dard CEI 825-1 (08/2001).

The different security levels the input/output answer are indicated for each connector in the chapter «Rear view of the

machine». Two security levels are possible :

- Dangerous voltage (power supply, accessories, plugs ...).

- Very low security voltage.

Machinesecurity

This hardware is in conformity with the norm EN ISO12100-1 and EN ISO12100-2.

Electromagneticcompatibility

This hardware is in conformity with electromagnetic compatibility norms:

• EN 55022 - classe B ; EN 61000-3-2 ; EN 61000-3-3 (emission in residential, commercial, and light industrial

environment)

• EN 61000-6-2 (immunity in industrial environment)

All the cables used with this hardware must be in conformity with the electronic compatibility standards, norm EN 55022

- class B.

Electricalsecurity

Thismaterialis«class1».ThemainsplugMUSTalwaysbeconnectedtoaneutralsocket

andcomplywiththeregulationsinforceinthecountryofinstallation.Ifyoudonothave

aplugofthistype,haveoneinstalledbyanapprovedelectrician.Undernocircumstances

shouldyoudepartfromthisinstruction.

The manufacturer bears no responsibility towards any user where alterations have been carried out contrary to the ma-

nufacturer’s specications, notably with respect to electrical/electronic elements.

Anyoperation,otherthanthosementionedhere,mustonlybecarriedoutbyanapproved

Gravographtechnician.

Donottakethemachineaparttorepairorcleanit:thiswillvoidyourguarantee.

Thissymbolindicatesthatoncethisequipmenthasreachedtheendofitsusefullife,it

mustnotbedisposedofwithnon-sortedmunicipalwaste,inaccordancewiththeEuropean

Directive2002/96/EC.

The equipment must be disposed of at an appropriate collection point for processing,

sorting,andrecyclingofWasteElectricalandElectronicEquipment(DEEE).

The elements which compose Electrical and Electronic Equipment may contain

substanceswhichhaveharmfuleffectsontheenvironmentoronhumanhealth.

By following these instructions, you are helping the environment, contributing to the

preservation of our natural resources, and protecting human health.