Grouser Products Ag 240I User manual

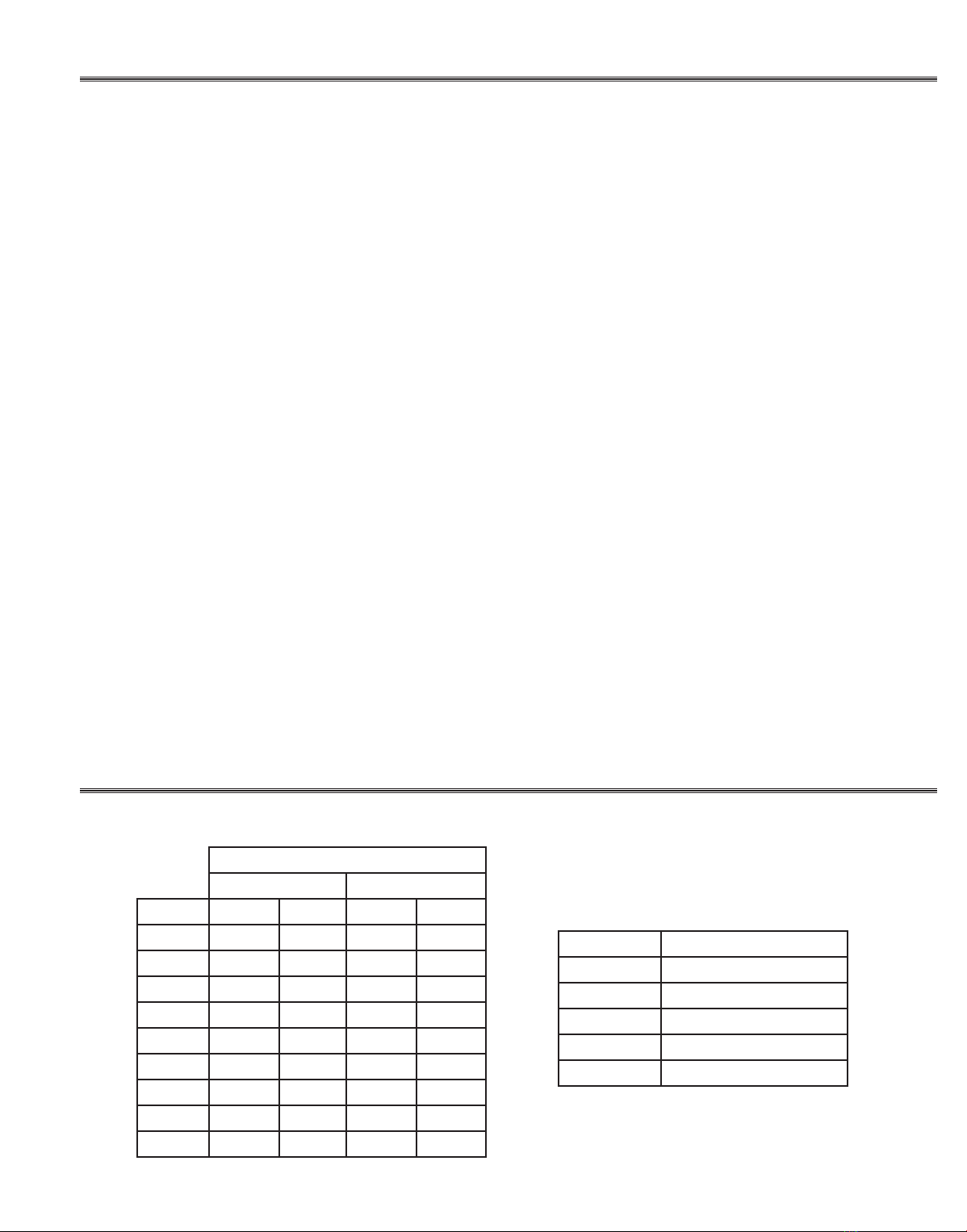

Other Grouser Products Tractor Accessories manuals

Grouser Products

Grouser Products Ag Pro Classic User manual

Grouser Products

Grouser Products New Holland TC 40 User manual

Grouser Products

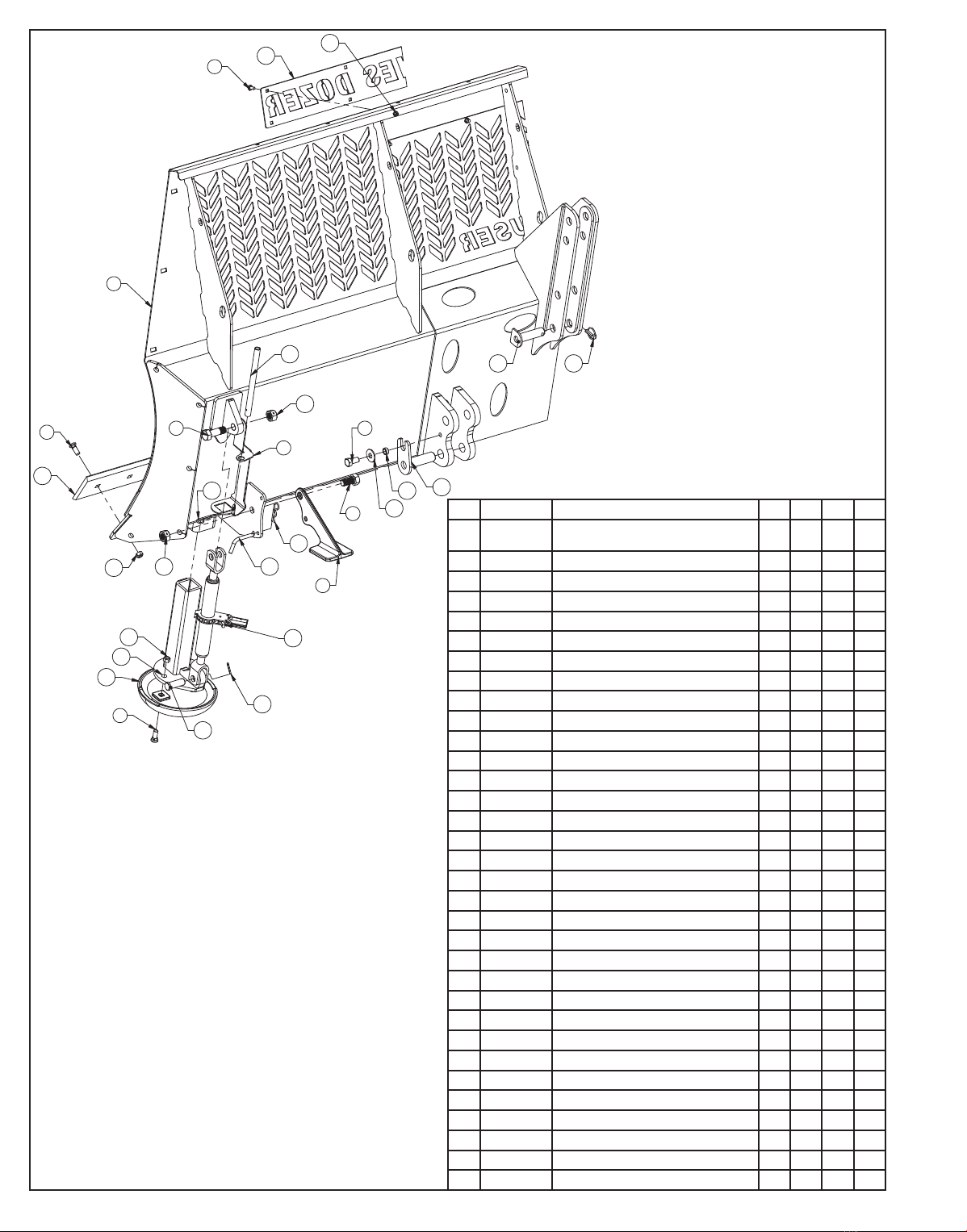

Grouser Products Ag Pro Plus HD User manual

Grouser Products

Grouser Products HD 19 U-Blade User manual

Grouser Products

Grouser Products Ag Pro Plus User manual

Grouser Products

Grouser Products 770HD Steiger Quad 550 User manual

Grouser Products

Grouser Products AG PRO PLUS NANT User manual

Grouser Products

Grouser Products RAM LOADER 40260 User manual

Grouser Products

Grouser Products 1300 Groomer User manual

Grouser Products

Grouser Products 1300 Groomer User manual

Grouser Products

Grouser Products Ag 240I User manual

Grouser Products

Grouser Products Ag Pro HD User manual

Grouser Products

Grouser Products AG240 User manual

Grouser Products

Grouser Products 760 User manual

Grouser Products

Grouser Products FH-443 User manual

Grouser Products

Grouser Products 770 - Plus User manual

Grouser Products

Grouser Products AG240 User manual

Grouser Products

Grouser Products Ag Pro Silage Special User manual

Grouser Products

Grouser Products 450 User manual

Popular Tractor Accessories manuals by other brands

Ventrac

Ventrac KD482 Operator's manual & parts drawings

Original Tractor Cabs

Original Tractor Cabs 4421381 Assembly instructions and parts list

Degelman

Degelman Landroller Operator's & parts manual

Bush Hog

Bush Hog BS1 Series Operator's manual

MX

MX MX A104 user manual

Bush Hog

Bush Hog DSP8 Operator's manual