Grundfos DPK Series User manual

Other Grundfos Water Pump manuals

Grundfos

Grundfos MTB Series User manual

Grundfos

Grundfos MGE F Operating instructions

Grundfos

Grundfos Unilift KP 150 User manual

Grundfos

Grundfos UPS3 15-50/65 User manual

Grundfos

Grundfos CME-Plus User manual

Grundfos

Grundfos KPL User manual

Grundfos

Grundfos Fire NKF Series User manual

Grundfos

Grundfos DMX 226 User manual

Grundfos

Grundfos SCALA1 User manual

Grundfos

Grundfos MS Series User manual

Grundfos

Grundfos UNILIFT AP35B User manual

Grundfos

Grundfos MQ 3-25 User manual

Grundfos

Grundfos MAGNA 2000 Series User manual

Grundfos

Grundfos UPM3 Parts list manual

Grundfos

Grundfos alpha2 l User manual

Grundfos

Grundfos SL1.50 User manual

Grundfos

Grundfos MAGNA3 25-100 (N) User manual

Grundfos

Grundfos NB User manual

Grundfos

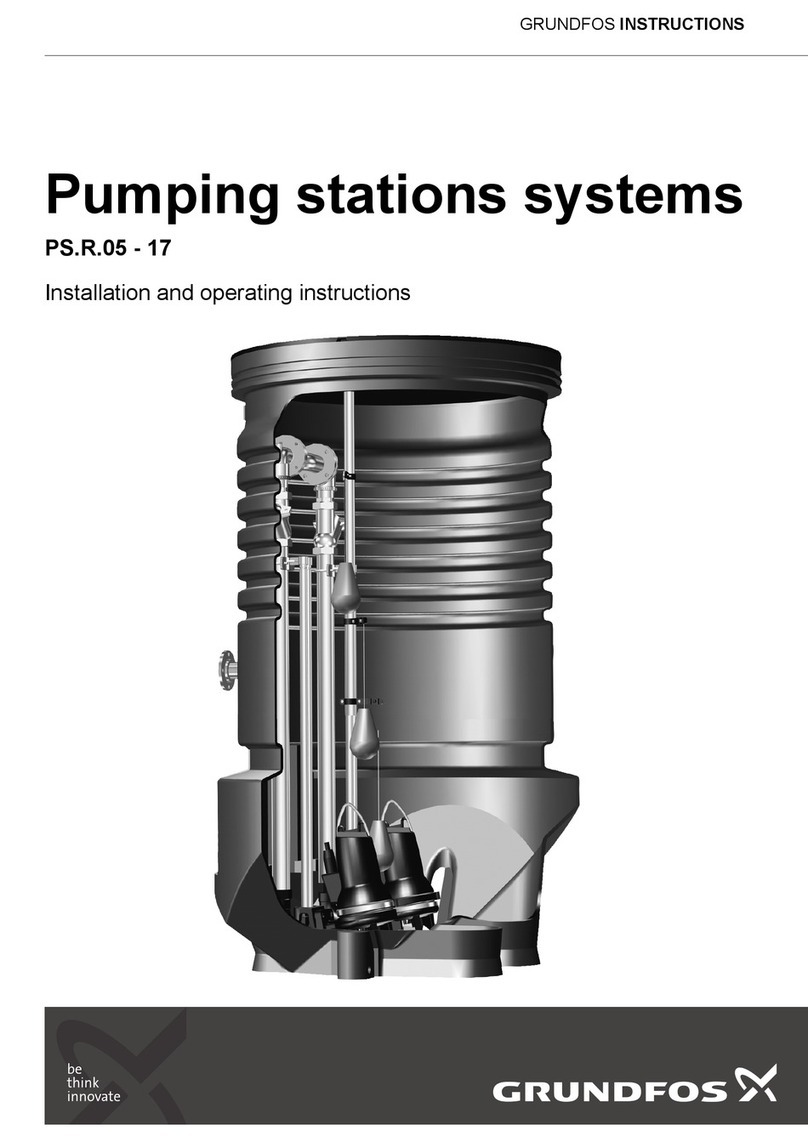

Grundfos PS.R.05 User manual

Grundfos

Grundfos CRE Series User manual

Popular Water Pump manuals by other brands

DUROMAX

DUROMAX XP WX Series user manual

BRINKMANN PUMPS

BRINKMANN PUMPS SBF550 operating instructions

Franklin Electric

Franklin Electric IPS Installation & operation manual

Xylem

Xylem e-1532 Series instruction manual

Milton Roy

Milton Roy PRIMEROYAL instruction manual

STA-RITE

STA-RITE ST33APP owner's manual