i

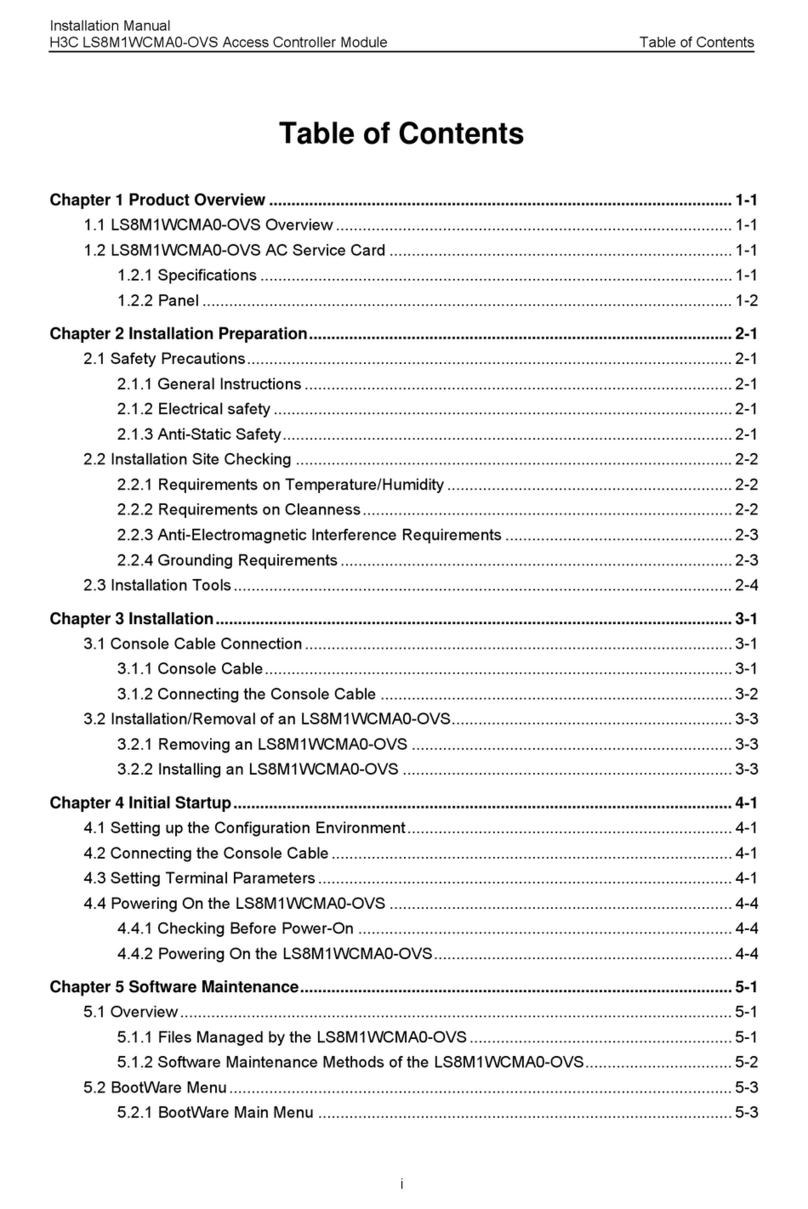

Contents

Preparing for installation ················································································· 1

Safety recommendations ···································································································································1

General safety recommendations ··············································································································1

Electrical safety ··········································································································································1

Examining the installation site····························································································································1

Temperature and humidity ·························································································································2

Cleanliness·················································································································································2

Cooling ·······················································································································································2

ESD prevention ··········································································································································3

EMI·····························································································································································3

Lightning protection····································································································································3

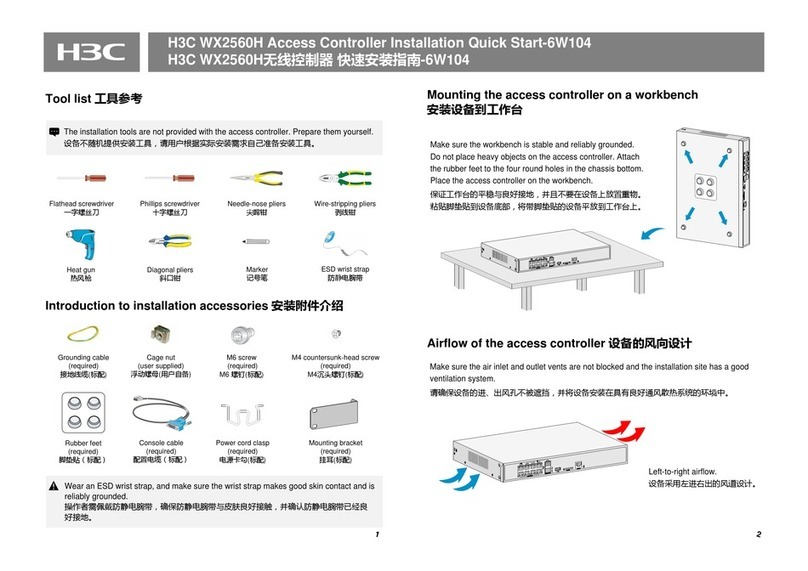

Installation accessories······································································································································3

Pre-installation checklist ····································································································································4

Installing the device ························································································ 5

Confirming installation preparations···················································································································5

Installation flow ··················································································································································5

Mounting the device on a workbench ················································································································5

Grounding the device·········································································································································6

Attaching the ring terminal to the grounding cable·····················································································6

Connecting the grounding cable ················································································································7

Connecting the device to the network················································································································7

Connecting the power adapter···························································································································8

Verifying the installation ·····································································································································8

Starting the device ·············································································································································9

Troubleshooting ···························································································· 10

Power failure ····················································································································································10

Symptom ··················································································································································10

Solution ····················································································································································10

Software loading failure ···································································································································10

Symptom ··················································································································································10

Solution ····················································································································································10

Hardware management and maintenance···················································· 11

Displaying hardware information for the device ·······························································································11

Displaying software and hardware version information for the device ·····················································11

Displaying operational statistics for the device ························································································11

Displaying detailed information about the device·····················································································12

Displaying the electronic label data for the device ···················································································12

Displaying the CPU usage of the device··································································································13

Displaying the memory usage of the device ····························································································13

Rebooting the device ·······································································································································14

Restrictions and guidelines ······················································································································14

Configuration procedure···························································································································15

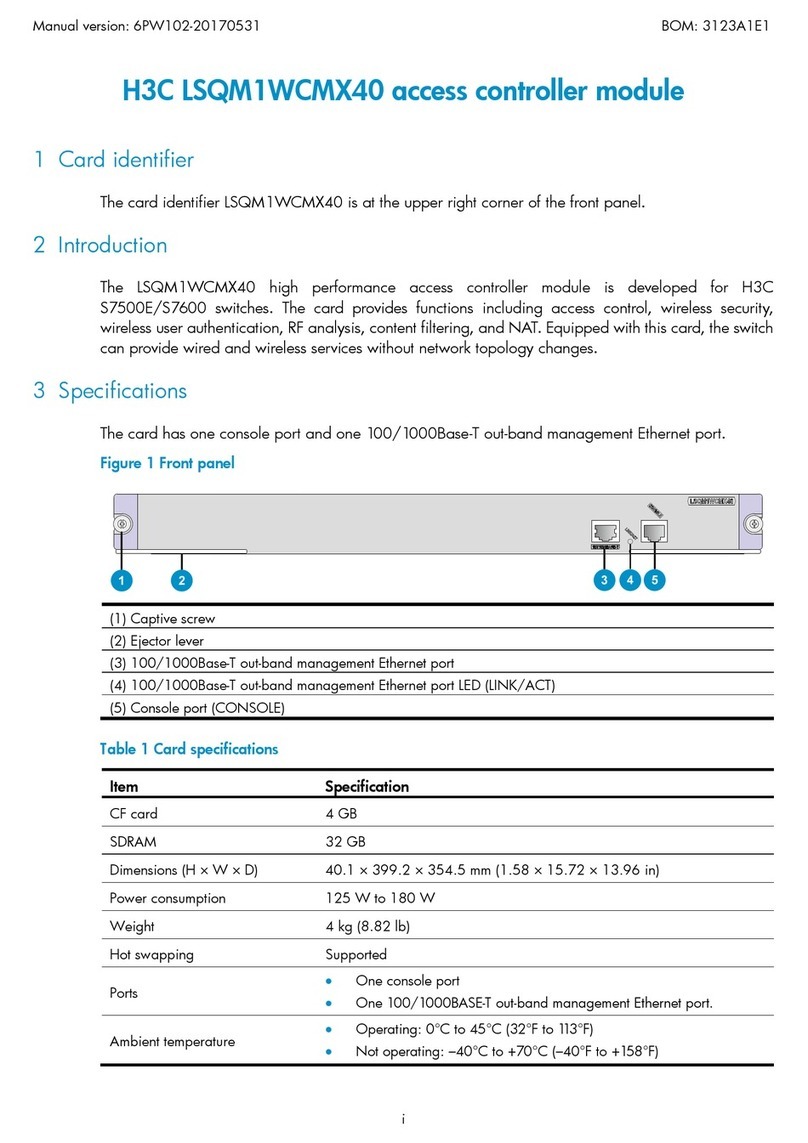

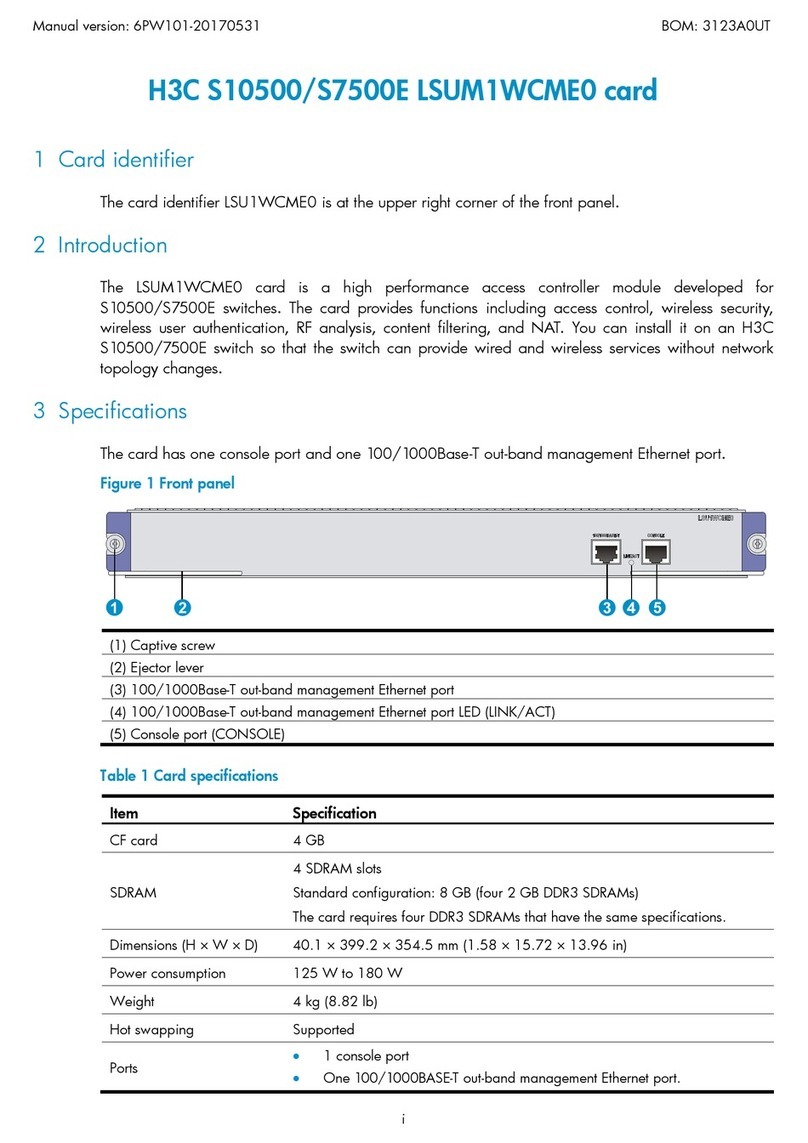

Appendix A Chassis views and technical specifications ······························· 16

Chassis views ··················································································································································16

Technical specifications ···································································································································16

Interface arrangement······································································································································17

Appendix B LEDs·························································································· 18

Index ············································································································· 19