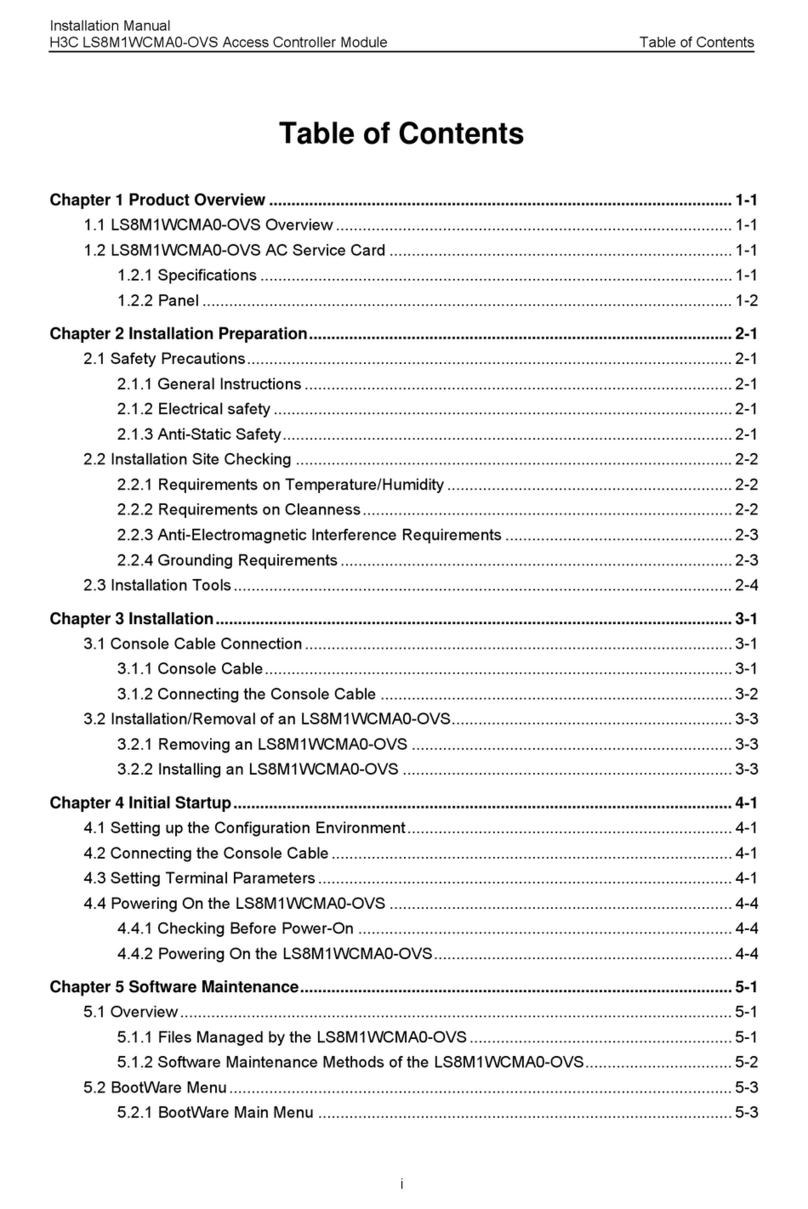

1

Preparing for installation

Safety recommendations

To avoid any equipment damage or bodily injury, read the following safety recommendations before

installation. Note that the recommendations do not cover every possible hazardous condition.

General safety recommendations

•Do not place the device on an unstable case or desk. The device might be severely damaged in

case of a fall.

•Make sure the ground is dry and flat and anti-slip measures are in place.

•Keep the chassis and installation tools away from walk areas.

•Keep the chassis clean and dust-free.

•Do not place the device near water or in a damp environment. Prevent water or moisture from

entering the device chassis.

•Ensure good ventilation of the equipment room and keep the air inlet and outlet vents of the device

free of obstruction.

•Make sure the device operates in the voltage range as required.

•Use a screwdriver to fasten screws.

•To prevent condensation, perform the following tasks:

{Unpack the device a minimum of half an hour after you move the device from a location below

0°C (32°F) to the equipment room.

{Power on the device a minimum of 2 hours after you move the device from a location below 0°C

(32°F) to the equipment room.

Electrical safety

•Carefully examine your work area for possible hazards, such as moist floors, ungrounded power

extension cables, or missing safety grounds.

•Locate the emergency power-off switch in the room before installation. Shut off the power

immediately if an accident occurs.

•Unplug all the external cables (including power cables) before moving the chassis.

•Do not work alone when the device has power.

•Always check that the power has been disconnected.