Kort bruksanvisning

!VARNING!

Observera: Läs tillverkarens ursprungliga instruktioner före användning. Dessa kan laddas ner från www.halder.com/downloadcenter (1).

Gängad lyftögla är gjord för att lyfta och hålla gods (inte människor!!).

Gängad lyftögla inte gjord för konstant roterande last.

Smuts (dvs. damm, olja etc.) kan påverka lyftöglans funktionalitet.

Användadet av skadade lyftöglor kan vara farligt. Före användning undersök noga den gängade lyftöglan (dvs deformering, revor, sprickor, korrosion, avsaknad av

gängor, frigörande funktion). Gängade lyftöglor måste skruvas in helt i korrekt gänga så den ligger direct mot ytan. Vid insättning av gängad lyftögla måste rotation

av lasten förhindras. Undvik slag och stötar mot de gängade lyftöglorna, även när de inte används.

Skadade lyftöglor skall tas ur drift omedelbart.

Det är inte tillåtet att:

- märka gängade lyftöglor med färg (särskilt röd)

- använda gängade lyftöglan efter att den passerat 20,000 lyft

Handhavande samt underhåll av gängad lyftögla får endast utföras av kvalicerad eller utbildad personal. Gängade lyftöglor får endast användas efter det att man läst

tillverkarens instruktioner.

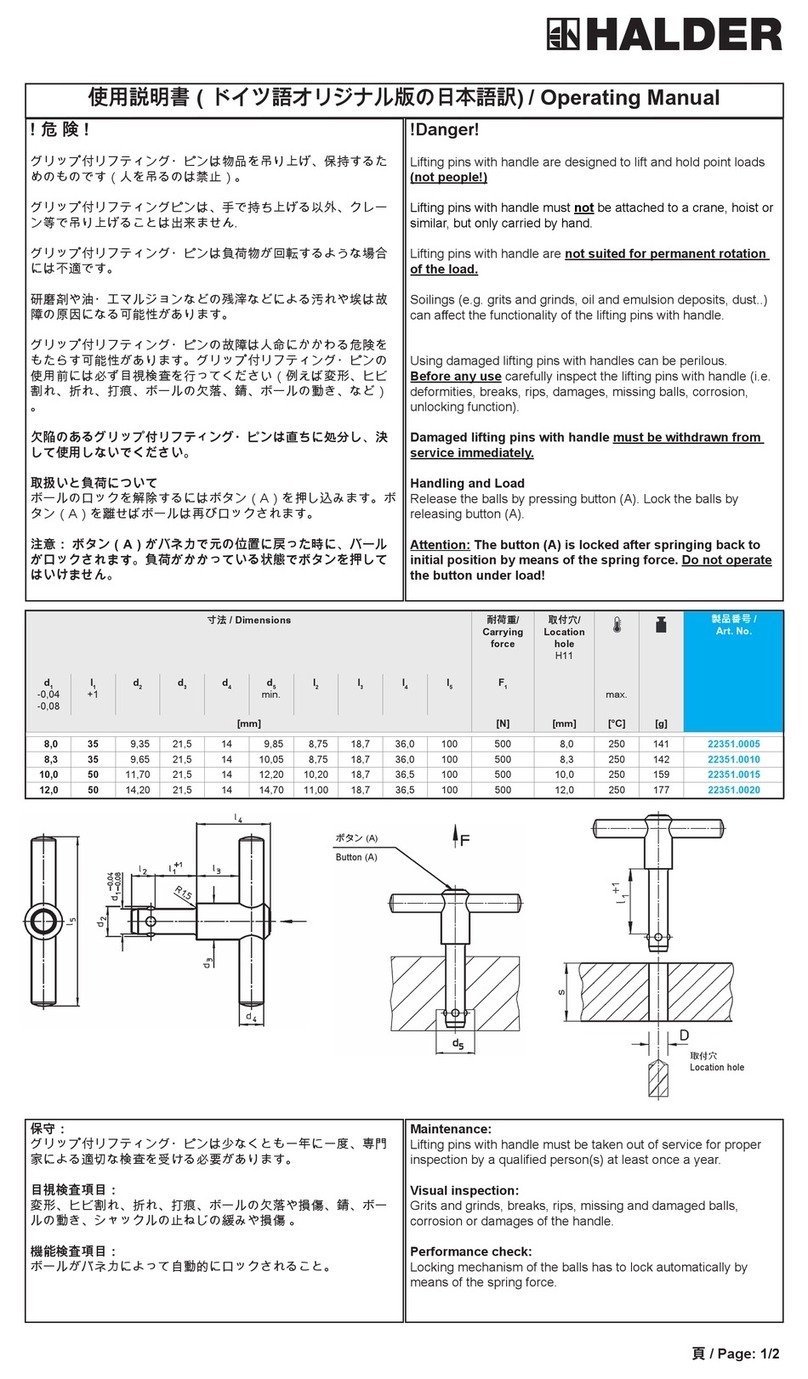

Hantering och belastning

För att frigöra gängorna, tryck på knappen (A). För att låsa kulorna, släpp knappen (A). Gängade lyftöglor måste skruvas in helt.

Not: Knappen (A) är låst efter att med hjälp av fjädermotståndet åter fjädrat till utgångsläget. Använd inte knappen vid laddning.

Belastningsirorna F1/ F2/ F3(Se sidan 2) Gäller endast lyftapplikationer med stål.

Underhåll

Gängade lyftöglor måste tas ur drift och besiktas av en kvalicerad person minst en gång per år.

Okulärbesiktning:

Revor, sprickor, korrosion, avsaknad av eller skadade gängor, damm och smuts, skruv skadad vid bygeln.

Funktionskontroll:

- de gängade elementen måste låsas automatiskt med fjäderkraften

-säkerställ full rörlighet av öglan

Sida / Page: 1

Short Instruction Manual

!DANGER!

Attention: Read the original operating instructions before use. These can be downloaded from www.halder.com/downloadcenter (1).

Threaded lifting pins are designed to lift and hold point loads (not people!!).

Threaded lifting pins are not suited for the rotation of the load.

Soilings (e.g. grits and grinds, oil and emulsion deposits, dust …) can aect the functioning of the threaded lifting pins.

Using damaged threaded lifting pins can be perilous. Before any use carefully inspect the threaded lifting pins (i.e. deformities, breaks, rips, damages, missing threaded

elements, corrosion, unlocking function). Threaded lifting pins must be screwed completely into a thread that is true to gauge and bear completely on the bearing

surface. When inserting a threaded lifting pin, the rotation of the load must be prevented. Please avoid direct impacts to the threaded lifting pins also if those are

not in use.

Damaged threaded lifting pins must be withdrawn from service immediately.

It is prohibited:

- to mark the threaded lifting pins in colour (especially red)

- to use the threaded lifting pins after exceeding 20,000 load cycles

The operation as well as work on the threaded lifting pins may only be carried out by qualied or instructed personnel. The threaded lifting pins may only be put into opera-

tion and serviced after the original operating instructions have been read.

Handling and Stress

To release the threaded elements, press button (A). To lock the threaded elements, release button (A). Threaded lifting pins must be screwed in completely.

Attention: The button (A) is locked after springing back to the initial position by means of the spring resistance.

Do not operate the button at charge.

The stress gures F1/ F2/ F3(see page 2) apply only to lifting applications with a steel retainer.

Maintenance:

Threaded lifting pins must be taken out of service for proper inspection by a qualied person(s) at least once a year.

Visual inspection:

Grits and grinds, breaks, rips, missing and damaged threaded elements, corrosion, screw union damages at shackle.

Performance check:

- the threaded elements must be locked automatically by the spring force

- full movement of the shackle must be ensured

FR: La traduction dans votre langue de cet manuel d‘instruction succinct et de la déclaration de conformité est disponible sur www.halder.com

IT: La traduzione di questo breve manuale di istruzioni nella vostra lingua con la Dichiarazione di conformità è disponibile nel sito www.halder.com.

ES: La traducción de este breve manual de instrucciones en su idioma con la Declaración de conformidad está disponible en www.halder.com.

CZ: Překladtohotokrátkéhonávoduvevašemjazycesprohlášenímoshodějekdispozicinawww.halder.com.

RO: Acestscurtinstructajdeutilizare,tradusînlimbadumneavoastră,împreunacuDeclarațiadeconformitatesuntdisponibilepentrudescărcarepewww.halder.com.

PL: TłumaczenietejkrótkiejinstrukcjiobsługinaTwójjęzykwrazzdeklaracjązgodnościjestdostępnenastroniewww.halder.com.

FI: Tämän lyhyen käyttöohjeen käännös omalla kielelläsi ja vaatimustenmukaisuusvakuutus ovat saatavilla osoitteessa www.halder.com.

SE: Enöversättningavdennakortainstruktionsmanualmedförsäkranomöverensstämmalennspådittsparkatthämtapåwww.halder.com.

NL: De vertaling van deze korte handleiding in uw eigen taal met conformiteitsverklaring is beschikbaar op www.halder.com.

KR: 적합선 선언과 함께 귀하의 언어로 번역이 된 짧은 설명서는 www.halder.com에서 확인 가능합니다.

CN: 可在 www.halder.com 上获得带有符合性声明的此简短说明手册的翻译版本。

TW: 可在 www.halder.com 上獲得帶有符合性聲明的此簡短說明手冊的翻譯版本。

JP: CE準拠の宣言書は、取扱説明書に付属していますが、以下URLでダウンロードできますwww.halder.com.

(1) Original operating instructions

(1) Original operating instructions