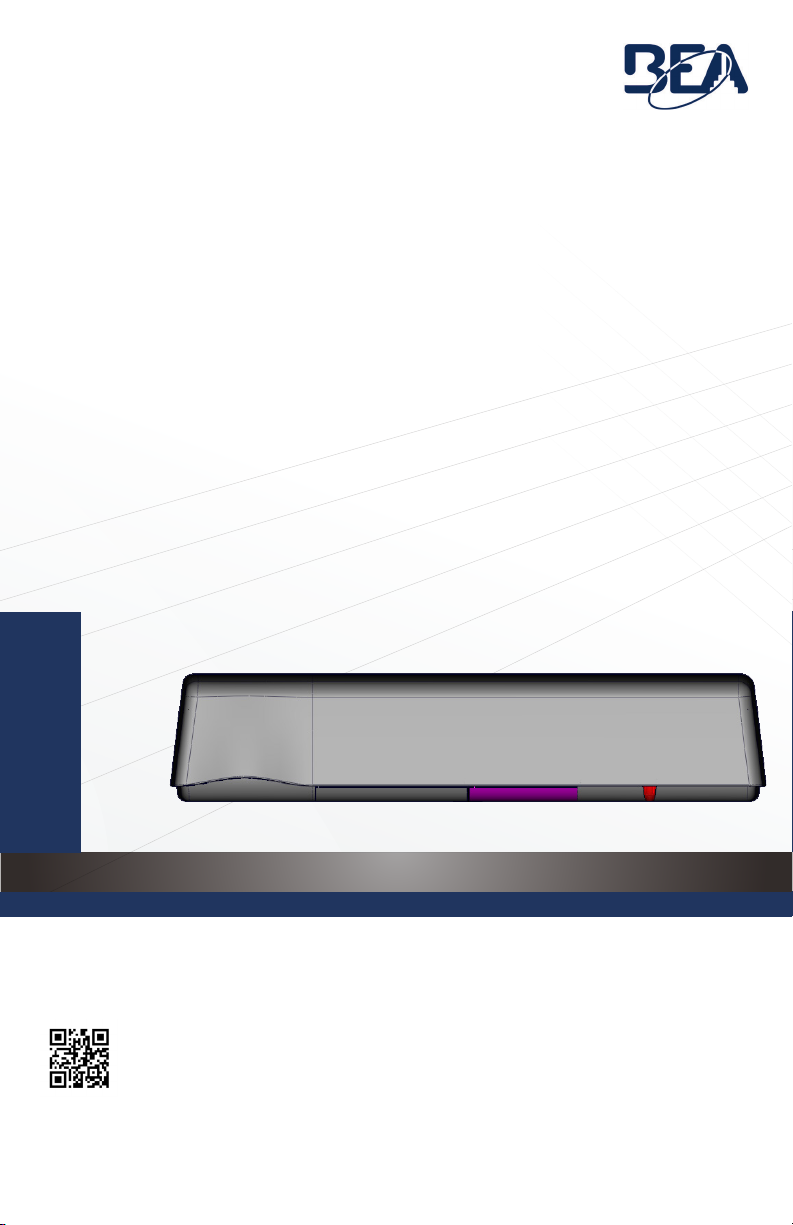

3

C3

C3

C2

C2

C1

C1

75.0034.02 ULTIMO 20211013 Page 9 of 16

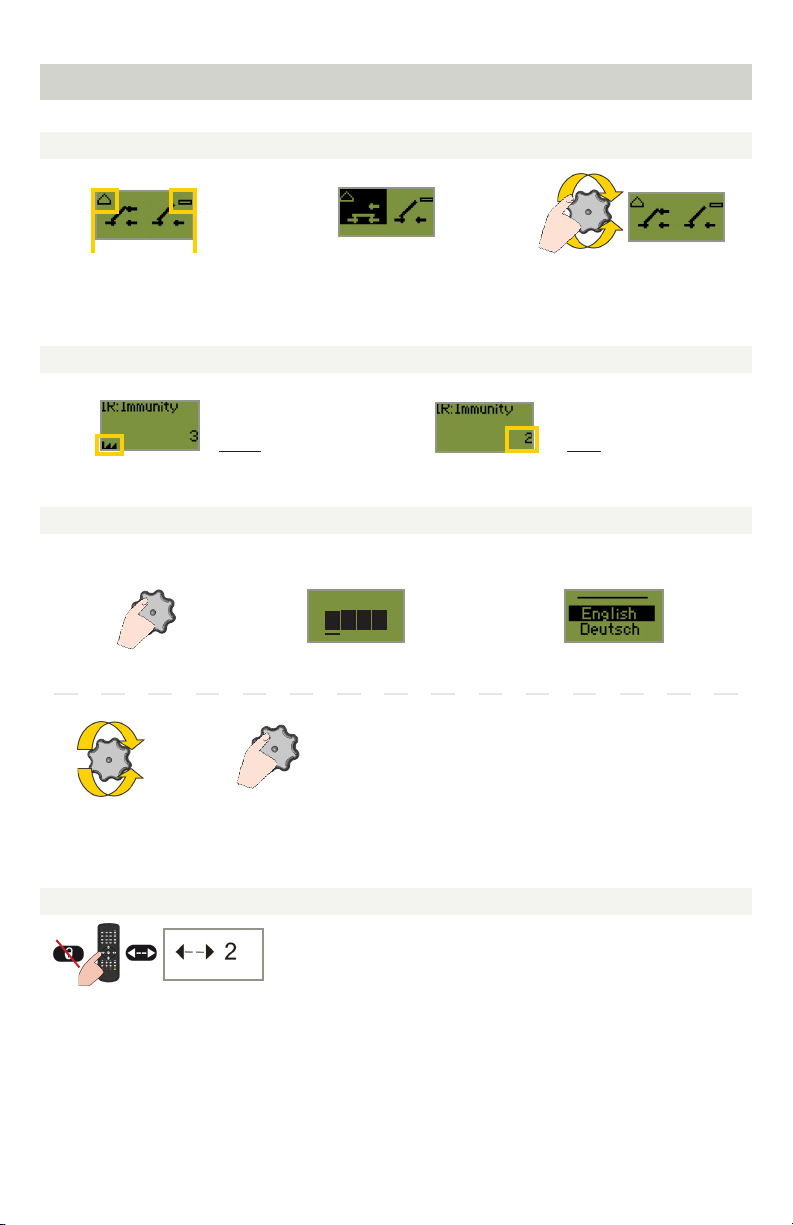

THRESHOLD SETTINGS

a dotted line indicates that

the given curtain is active

at full open, and inactive

during door closing cycle

(settings 2 and 5)

a solid line indicates that

the given curtain is active

at full open and partially

active during door closing

cycle (settings 1 and 4)

NON-THRESHOLD SETTINGS

a solid line indicates that

the given curtain is always

active (settings 3, 6, and 7)

* When IR:Curtains is set to 0, the AIR will not trigger the output for a period of 5 minutes.

After 5 minutes expires, IR:Curtains will revert back to the previously chosen setting.

GENERAL

the number of squares on

a line indicates the curtain

number (i.e. C1, C2, or C3)

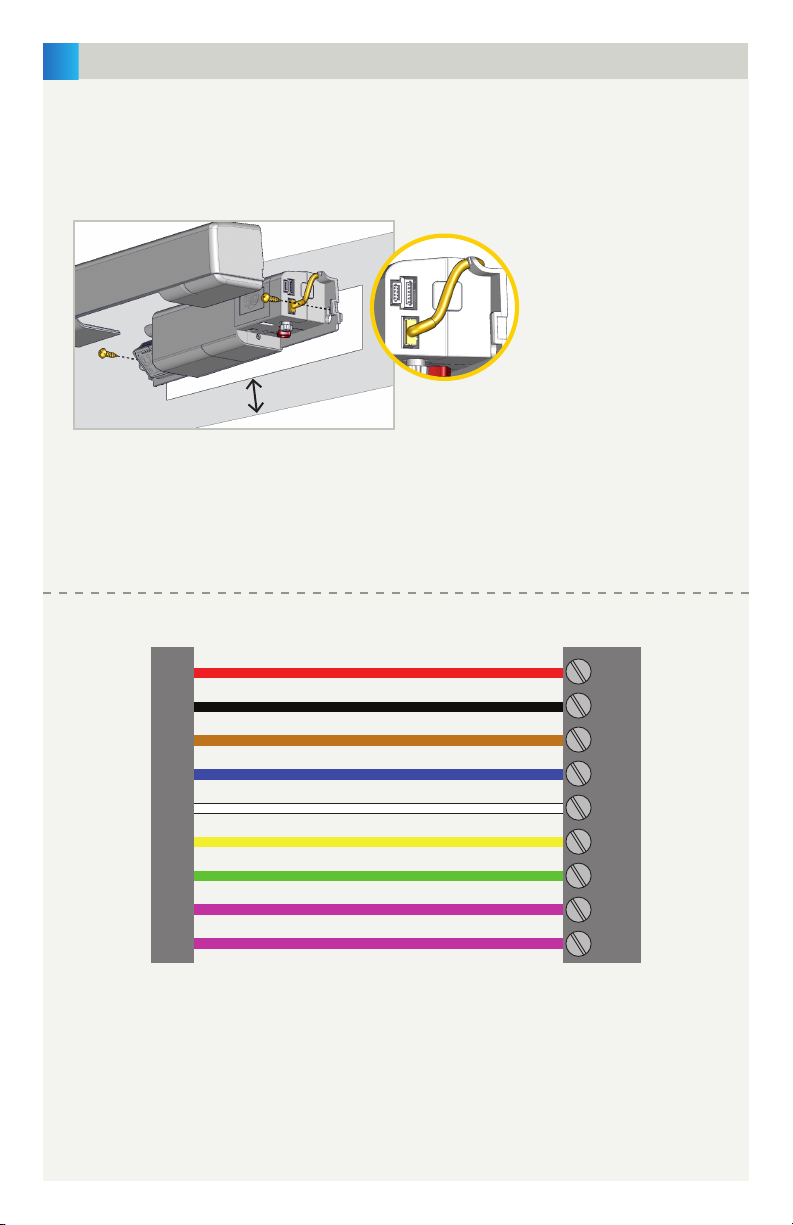

the rectangles on each

side of the setting number

represent sliding door

panels

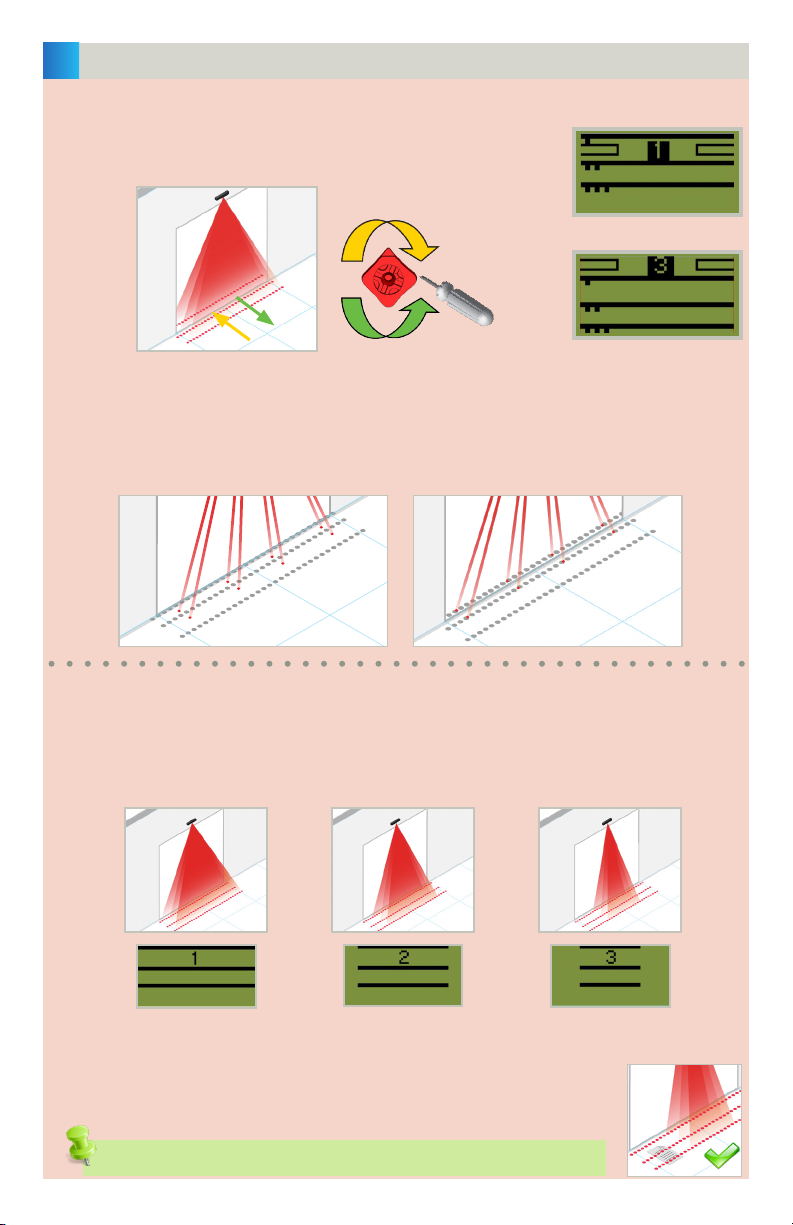

ACTIVE INFRARED SAFETY FIELD

NUMBER OF CURTAINS / POSITION OF CURTAINS

(IR:CURTAINS, MENU 1)

Choose the number and position of the AIR curtains based on your application.

The sensor is defaulted to Non-Threshold setting (3). If threshold is desired, you may choose

Threshold setting 1, 2, 4, or 5; be sure that the curtain placement matches the LCD screen.

If necessary, use visible spots and red adjustment knob to position properly (see page 10).

UNDERSTANDING THE LCD "CURTAINS" GRAPHICS

1. Activate the four visible spots (press gray knob twice) to verify the

position of the AIR curtains.

Visibility depends on external conditions. When spots are not

visible, use the Spotfinder to locate the curtains.

ANGLE

THRESHOLD NON-THRESHOLD

0 1 2 3 (default)

4 5 6 7

double

press

OR