OPERATING INSTRUCTIONS

General Information

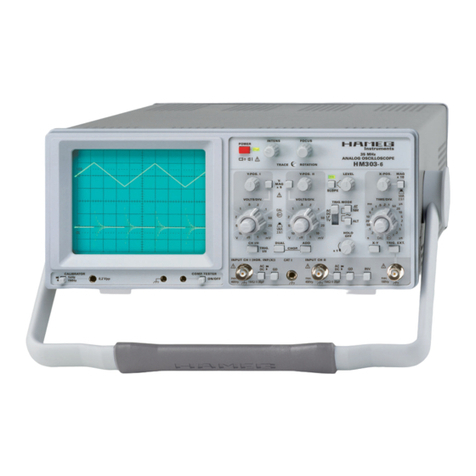

The new HM203-4 is as easy to use as all HAMEG in

struments. Technologically it represents the latest state

of engineering in this price range. This is particularly

illustrated by the increased use of monolithic integrated

circuits. The logical arrangement of the controls and con

nectors on the front panel ensures that the user will

quickly become familiar with the operation of the instru

ment. However, even experienced operators are advised

to read the following instructions thoroughly, as they in

clude important information relating to the use of the

HM203-4.

The front panel is subdivided into three sections accord

ing to the various functions. The X-MAGN. X5 pushbut

ton, the calibrator output (CAL. 0.2V), and the COMPO

NENT TESTER pushbutton and its measuring socket are

located on the left directly below the screen of the

cathode-ray tube (CRT).

The X-Section, located on the upper right, contains the

red POWER pushbutton and indicating lamp, the IN-

TENS., FOCUS, and TR (trace rotation) controls. To the

right of them, all controls and switches for TIMEBASE

and triggering and the TRIG. EXT. input connector are

arranged.

The lower Y-Section contains the controls for the vertical

deflection system. On the right and left in this section are

located: vertical input connector, DC-AC-GD input cou

pling slide switch, Y-POS. control, AMPL. attenuator

switch with variable control, and ground jack. All these

controls and connectors exist in duplicate for each of the

Channels I and II. Four pushbuttons for selecting the

operating mode are arranged below the attenuator swit

ches: INVERT I, CHI/II — TRIG. I/II, DUAL, and

ALT/C H O P- I + 11

The instrument is so designed that even incorrect opera

tion will not cause serious damage. The pushbuttons

control only minor functions, and it is recommended that

before commencement of operation all pushbuttons are

in the " o u t" position. After this the pushbuttons can be

operated depending upon the mode of operation

required. For a better understanding of these Operating

Instructions the front panel picture at the end of these

instructions can be unfolded for reference alongside the

text.

The HM203 accepts all signals from DC (direct voltage)

up to a frequency of at least 20MHz (-3dB). For sine-

wave voltages the upper frequency limit will be

30-35 MHz. However, in this higher frequency range the

vertical display height on the screen is limited to approx.

4-5cm . In addition, problems of time resolution also

arise. For example, with 2 5 MHz and the fastest ad

justable sweep rate (40ns/cm), one cycle will be

displayed every 1 cm. The tolerance on indicated values

amounts to ±3% in both deflection directions. All values

to be measured can therefore be determined reatively ac

curately. However, from approximately 6 MHz upwards

the measuring error will increase as a result of loss of

gain. At 12MHz this reduction is about 10%. Thus, ap

proximately 11 % should be added to the measured

voltage at this frequency. As the bandwidth of the

amplifiers differ (normally between 20 and 2 5 MHz), the

measured values in the upper limit range cannot be

defined exactly. Additionally, as already mentioned, for

frequencies above 20MHz the dynamic range of the

display height steadily decreases. The vertical amplifier is

designed so that the transmission performance is not

affected by its own overshoot.

Warranty

Before being shipped each instrument must pass a 10

hour quality control test. Almost every early failure can be

detected by means of intermittent operation during this

test. Nevertheless, a component may fail but only after a

longer period of operation. Therefore, all HAMEG in

struments are under warranty for a period of one year,

provided that the instrument has not undergone any

modifications. HAMEG will repair or replace products

which prove to be defective during the warranty period.

No other warranty is expressed or implied. HAMEG is not

liable for consequential damages. It is recommended that

the instrument be repackaged in the original manner for

maximum protection. We regret that transportation

damage due to poor packaging is not covered by this

warranty.

In case of any complaint, attach a tag to the instrument

with a description of the fault observed. Please supply

name and department, address and telephone number to

ensure rapid service.

Safety

This instrument is designed and tested according to inter

national safety standards (e.g. IEC 348: Safety re

quirements for electronic measuring apparatus). The

instrument has left the factory in perfect safety condition.

To preserve this state and to ensure operation without

danger, the user must observe all advises and warning

remarks in these Operating, Test, and Service Instruc

tions. The case, chassis, and all measuring terminals

are connected to the Safety Earth conductor. The

specification of the instrument corresponds to Safety

Class / (three-conductor AC power cable). The grounded

accessible metal parts (case, sockets, jacks) and the

power line circuit of the HM203 are tested against one

Printed in West Germany (1 983) Ml 203-4