Hardi HC5500 User manual

CONTROLLER

HC5500

Service Manual – SW 4.XX

679060-702 – Version 7.02

GB – 11.2008

www.hardi-international.com

Page 2 of 87

Service Manual HC5500

Table of contents:

INTRODUCTION.................................................................................................................................................. 4

SPECIFICATIONS............................................................................................................................................... 5

HARDI HC5500 CONTROLLER:........................................................................................................................................5

HC5500, SPRAY BOX AND JOBCOM POWER SUPPLY AND PROTECTION ..............................................................................5

FUNCTIONS AND FUNCTIONALITY ................................................................................................................. 6

CONNECTORS AT THE BACK OF THE HC5500:....................................................................................................................6

SPRAYER CONNECTION:.....................................................................................................................................................7

Fluid cables..................................................................................................................................................................7

COMMANDER:...........................................................................................................................................................7

NAVIGATOR: ..............................................................................................................................................................7

NAVIGATOR or RANGER:..........................................................................................................................................7

Hydraulic cables..........................................................................................................................................................8

Commander with JobCom: ..........................................................................................................................................8

Navigator with JobCom:..............................................................................................................................................8

Commander, Navigator and Ranger without JobCom:................................................................................................8

Master..........................................................................................................................................................................8

AMP CONNECTORS ...........................................................................................................................................................9

OPTIONAL EXTRAS FOR THE HC5500 ..............................................................................................................................10

Printer........................................................................................................................................................................10

Foot pedal for main ON/OFF function......................................................................................................................11

SENSORS:.........................................................................................................................................................................12

Speed sensor for Tractor: Wheel, gearbox or radar..................................................................................................13

Pressure sensor..........................................................................................................................................................13

Fan speed on TWIN ...................................................................................................................................................14

TankGauge.................................................................................................................................................................15

End nozzle kit.............................................................................................................................................................17

EXTENDED MENU FOR SW 4.00..................................................................................................................... 18

Extended Menu 1 Language.......................................................................................................................................18

Extended Menu 2 Unit ...............................................................................................................................................18

Extended Menu 3 Sprayer type ..................................................................................................................................19

Extended Menu 4 Data exchange...............................................................................................................................20

Extended Menu 5 Optional sensors............................................................................................................................21

Extended Menu 6 Service interval..............................................................................................................................22

Extended Menu 7 Factory settings.............................................................................................................................22

Extended Menu 9 Jobcom..........................................................................................................................................26

TRACK SETTING IN EXTENDED MENU:........................................................................................................ 29

Menu E 8.4.1 Enable..................................................................................................................................................29

Menu E 8.4.2 Sensor test............................................................................................................................................29

Intellitrack rear sensor calibration:...........................................................................................................................30

Menu: E 8.4.3 Chassis...............................................................................................................................................32

Menu: E 8.4.4 Sprayer drawbar ................................................................................................................................32

SafeTrack on COMMANDER ....................................................................................................................................32

IntelliTrack on NAVIGATOR.....................................................................................................................................32

Menu E 8.4.5 Manual angling ...................................................................................................................................33

Menu E 8.4.6 Boom sensor ........................................................................................................................................33

Menu E 8.4.7 Error print...........................................................................................................................................33

Menu E 8.4.8 Minimum radius...................................................................................................................................33

Menu E 8.4.9 Half steer.............................................................................................................................................33

Select half steer for SPC/SPZ boom, only active with 2 boom sensors......................................................................33

Menu E 8.4.10 Safety factor.......................................................................................................................................33

Menu E 8.4.11 Boom type..........................................................................................................................................33

Page 3 of 87

LOOKAHEAD ...................................................................................................................................................................34

What is the LookAhead? ............................................................................................................................................34

How to use the LookAhead.........................................................................................................................................35

Calibration of LookAhead..........................................................................................................................................36

Pressure regulation valve for LookAhead..................................................................................................................36

SOFTWARE....................................................................................................................................................... 37

Software program for the controller..........................................................................................................................38

Communication cable ................................................................................................................................................40

USB to RS232 Converter............................................................................................................................................41

SOFTWARE UPLOAD HC5500........................................................................................................................ 44

SOFTWARE UPLOAD JOBCOM...................................................................................................................... 49

HANDLING THE CONFIGURATION FILE........................................................................................................ 55

Save the configuration file to the PC:........................................................................................................................55

Send the configuration file to the HC5500: ...............................................................................................................56

DUMP OF DATA FROM HC5500 CONTROLLER............................................................................................ 57

Configuration of HC5500 to dump data ....................................................................................................................57

DUMP DATA FROM HC5500............................................................................................................................ 59

CONFIGURATION OF HYPERTERMINAL....................................................................................................... 60

HANDLING DATA FROM HYPERTERMINAL ................................................................................................. 64

LOCAL LANGUAGE MAINTENANCE.............................................................................................................. 66

How to translate a language file................................................................................................................................66

New software and local language..............................................................................................................................66

Transfer the language file from PC to HC5500.........................................................................................................67

Download language file from HC5500 to PC:...........................................................................................................68

PCB’S ................................................................................................................................................................ 70

PCB for Liquid...........................................................................................................................................................70

Breakout PCB ............................................................................................................................................................70

PCB for section valves, 9 sections .............................................................................................................................71

PCB for section valves 13 sections ............................................................................................................................73

PCB for hydraulic......................................................................................................................................................74

PCB for SafeTrack.....................................................................................................................................................75

PCB for Jobcom.........................................................................................................................................................76

Resetting the Jobcom .................................................................................................................................................76

FAULT FINDING ON HC5500 & JOBCOM....................................................................................................... 77

LED´s on Jobcom.......................................................................................................................................................77

Thermal fuses on the HC5500 and Spray box............................................................................................................78

CABLES CONFIGURATION............................................................................................................................. 79

37–39 pole cable between Spray II and the JobCom / Breakout or 9 sec. PCB ........................................................79

37–39 pole cable between Hydraulic Box and the JobCom / Breakout PCB.............................................................80

DB37M–DB37F pole cable between JobCom / Breakout PCB to 13 sec. PCB.........................................................81

DB37M–DB37F pole cable between JobCom / Breakout PCB to 9 sec. PCB...........................................................82

DB25M–DB25F pole HY cable..................................................................................................................................83

Cable for LPZ/DH......................................................................................................................................................84

Cable for VHZ............................................................................................................................................................85

15F-15F DSUB Cable................................................................................................................................................86

REVISION.......................................................................................................................................................... 87

Page 4 of 87

Introduction

This manual covers the HARDI Controller 5500 and the options it supports like SafeTrack

on the Commander and IntelliTrack on Navigator.

It assumes the reader has knowledge of the more basic HC2500. The menu systems,

calibration and operations of the HC5500 are built up from the HC2500. The sensors used

are also similar or the same.

This manual also at times has notes on the HC6500. This is because the HC6500 is built up

around the HC5500 and has many similarities.

Page 5 of 87

Specifications

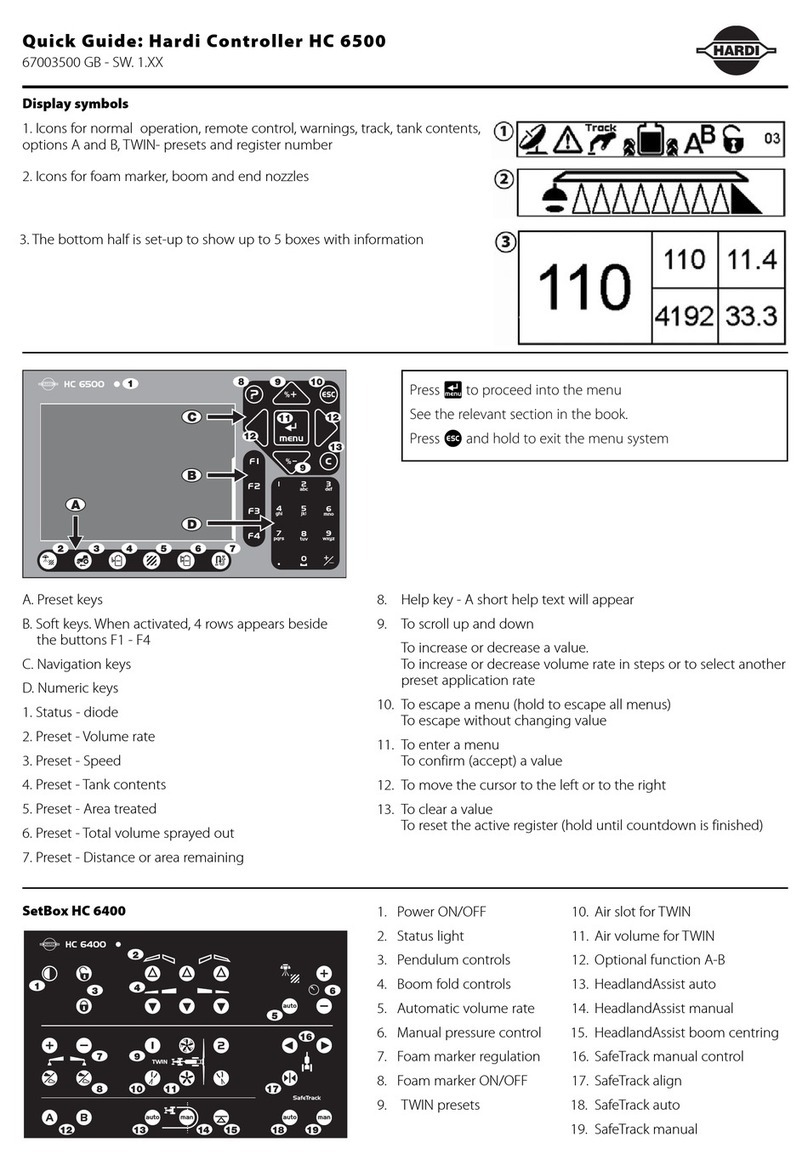

HARDI HC5500 Controller:

Display:

1. 4th line

2. 3rd line

3. Main Readout

4. Manual

5. External rate

6. Warning

7. Boom line status

8. Register no.

Navigation keys:

9. Multi function keys

Readout presets &

Short cuts:

10. Auto On

11. Remaining Distance

or Area

12. Volume used

13. Area covered

14. Tank volume

15. Speed

16. Volume rate

HC5500, Spray box and JobCom power supply and protection

Power supply:

Operating range: 9-16V DC

Controlled processor shut down: < 9 VDC

Protected against over voltage: 28 VDC

The electronics are protected against reverse polarisation of the power input.

Ambient temperature: – 5°C to + 70°C

Memory: Flash PROM non-volatile

Analog transducers typ. press. (Option 1):

Supply: 12 V

Input: 4 to 20 mA

Minimum speed for volume regulation: 0.5 km/h

Digital transducers type fan speed (option 2): Square signal

Frequency: 0.5 Hz to 2 kHz

Trigger high: 4.0 to 12.0 Volt DC

Trigger low: 0.0 to 2.0 Volt DC

Page 6 of 87

Functions and functionality

Connectors at the back of the HC5500:

The connector’s functions are:

A: COM 1:

This can be used for dumping data, receiving data or for the connection to the printer. Use

COM 1 for software updates.

B: COM 2:

This has the same function as COM 1, though not for software updates.

C: Control box:

This is used for the liquid control box Spray I or Spray II box.

D: AUX:

This is used if the tractor speed sensor or the foot pedal is connected to the HC5500.

Harness P/N 28027600 is necessary.

Page 7 of 87

Sprayer connection:

Fluid cables

Cables details can be found in the cables configuration chapter.

COMMANDER:

1. HC2500/5500

2. Spray II

3. Hydraulic Box

4. Cable: 26004200 L=17,5m

28028700 L=14m

28027500 L=11,5m

28028900 L=8m

28028800 L=5m

26003900 L=2m

26028300 L = 0,5m

5. JobCom or Breakout PCB

6. Cable P/N 26004900

7. 13 sec PCB P/N 26004800

NAVIGATOR:

1. HC5500

2. Spray II

3. Hydraulic Box

4. Cable P/N: 26004200 L = 17,5m

28028700 L=14m

28027500 L=11,5m

28028900 L=8m

28028800 L=5m

26003900 L=2m

26028300 L = 0,5m

5. JobCom

6. Cable P/N 26023800

7. 9 sec PCB P/N 72173900

NAVIGATOR or RANGER:

1. HC2500/5500

2. Spray II

3. Hydraulic Box

4. Cable: 26004200 L = 17,5m

28028700 L=14m

28027500 L=11,5m

28028900 L=8m

28028800 L=5m

26003900 L=2m

26028300 L = 0,5m

7. 9 sec PCB P/N 72173900

Page 8 of 87

Hydraulic cables

Cables details can be found in the cables configuration chapter.

Commander with JobCom:

1. HC5500

2. Spray II Box

3. Hydraulic Box

4. Cable P/N: 72236600, L=5m

72236400, L=8m

5. JobCom with DAH Interface

6. Cable P/N 26016900

7. Hydraulic junction box

9. SafeTrack and lock cable P/N26024000

Navigator with JobCom:

1. HC5500

2. Spray II Box

3. Hydraulic Box

4. Cable P/N: 72236600, L=5m

72236400, L=8m

5. JobCom DAH Interface

6. Cable P/N 26016900

7. Hydraulic junction box

10. IntelliTrack cable P/N26024100

Commander, Navigator and Ranger without JobCom:

1. HC5500

2. Spray II Box

3. Hydraulic Box

4. Cable P/N: 26008400, L=8m

6. Cable P/N 26016900

7. Hydraulic junction box

11. Breakout PCB

Master

1. HC5500

2. Spray II Box

3. Hydraulic Box

4. Cable P/N: 72168100, L=8m

72278300, L=12m

7. Hydraulic junction box

Page 9 of 87

AMP connectors

The AMP connectors have each of the legs numbered so they are easy to identify. The

table shows how the wires are mounted in the plug and what function the wires have.

AMP plug Pin & Wire connection

AMP Super Seal Function Colour

2 + Brown

3 Signal Blue

1 - Black

Page 10 of 87

Optional extras for the HC5500

Printer

A printer can be fitted for the HC5500, as shown on Picture 1.

Picture 1: Printer for the HC5500

The printer can print out several kinds of data from the HC5500.

Picture 2 is an example of a printed register and Picture 3 a printed configuration.

Register printout gives the user sprayed area, volume rate that has been used etc.

The configuration print is very useful for a quick overview of how the controller is set up and

for spotting errors.

Picture 2: Print of the register Picture 3: Print of the configuration

Printer

Page 11 of 87

The connection from the printer to the HC5500 is done through COM 1 or COM 2. The

printer is powered through the COM port so there is only one plug for the connection.

The configuration of the com port is done in Extended Menu 4.

In menu E4.1.1 Equipment type, Printer must be chosen and in menu E4.1.2 the baud rate

must be set to 9600.

In the section "Configuration of HC5500 to dump data” is a detailed description of the setup.

If the printer does not work, then check the connection to the COM port and see if it is

correct.

If it does not print, check the paper is threaded correctly (not reverse side).

Foot pedal for main ON/OFF function

The foot pedal is an extra option for the HC5500. The pedal is connected through the wire

harness that can be seen on Picture 4 and Picture 5.

The wire harness is plugged into the AUX connector.

The “Speed2” connector has GND on pin1, +12V on pin 2 and Speed signal on pin 3.

The “Switch” connector has GND on pin 1, +12V on pin 2 and Switch signal on pin 3.

Picture 4: Foot pedal for the HC5500 Picture 5: Wire harness for the HC5500

The setup of the foot pedal to the HC5500 is done in E8.5.1. The menu tree can be seen in

section “Extended Menu 8”. There are two choices depending on the switch type.

The HC5500 can be set to a toggle or a pulse function. The standard HARDI foot pedal is a

toggle type.

Page 12 of 87

Sensors:

Angle sensor Sensor AMP Con PCB

Blue Signal Signal 3Signal

Black GND GND 1-

Brown +12V +12V 2+

Speed, TWIN, Boom and SafeTrack lock

sensor

Hardi P/N 28047500

Type: Inductive

Range: 0-8mm

Signal: 0-200Hz

Operation indicator: Yellow light when

active (0,8V)

Power: 12V

Visual indicator: LED to indicate active

status

Hardi Pin assignment: Brown +

Blue signal

Black -

Front angle sensor:

Hardi P/N 26005700

Type: Potentiometer

Range: 0-70°

Signal: 0,5 - 4,5V

Centre position: 2,5 V

Power: 12V

Hardi Pin assignment: Brown +

Blue signal

Black -

SafeTrack rear sensor:

Hardi P/N 26005800

Type: Potentiometer

Range: 0-120°

Signal: 0,5 - 4,5V

Centre position: 2,5 V

Power: 12V

Hardi Pin assignment: Brown +

Blue signal

Black -

Page 13 of 87

Flow sensor:

Hardi P/N 72117500

Type: Inductive

Range: On, 0,2-0,5 V

Off, 6,5-7,0 V

Visual indicator: Red light at Off (0,8V)

Power: 12V

Hardi Pin assignment: Brown +

Blue signal

Black -

Pressure sensor:

Hardi P/N 842022

Type: Pressure

Range: 0-10 Bar

Signal: 4-20mA

Power supply: 8-30V

Hardi pin assignment: Brown +

Blue Signal

Black N/C

Speed sensor for Tractor: Wheel, gearbox or radar

The HC5500 can have several different kinds of speed sensors. It can have an inductive

sensor mounted on the back wheel, the same sensor as on the trailed sprayers, or it can be

connected to the tractors speed sensor, in the gearbox, or radar.

The sensors are connected to the HC5500 through wire harness on

Picture 5.

The signal from the tractor or the radar must be between 0 - 5 Volt and below 2,000 Hz.

Most radar’s have this signal range.

The signal from the tractors can however change a lot from brand to brand; consult your

manual or tractor dealer for more information.

The setup of the speed sensors in the HC5500 is done in the menu 3.1. Further instructions

about the connection and calibration can be found in the instruction book.

Pressure sensor

An optional 4 to 20 mAmp pressure sensor can be fitted to the liquid system.

With the sensor, the controller can switch to pressure based regulation when the flow drops

below the minimum rate measurable by the flow meter. Preventing LookAhead from winding

the pressure regulation valve down too far when driving very slowly.

In menu E8.1.7 the sensor has to be set to “Active”.

The sensor can be set for a minimum pressure. If the pressure drops below the set value,

pressure regulation stops.

The HC5500 has min and max pressure alarm that will be shown in the display menu.

The cable is connected to the “PCB for section valves”.

Page 14 of 87

The version of the PCB used depends of what type of sprayer the sensor in mounted on.

For the wire connections to the PCB, see section “PCB’s” on pages 70.

When the pressure sensor is mounted on the sprayer, the HC5500 is setup to the sensor. In

menu “5” on pages 21, the setup is shown.

The pressure sensor has a fixed measuring range in Bar or PSI.

In Menu E5.1.1 the minimum value is typed in and in menu E5.1.2 the maximum is typed in.

The measuring range is written on the pressure transducer. Our standard is 0 to 10 Bar.

Note that the sensor is ignored if the minimum input is less than 3 mAmp.

In menu E8.1.3 is the minimum allowed pressure typed in. In practice, this means the

regulation will stop if the pressure goes below this value.

These setting are done in the Extended Menu.

For a readout, the sensor must be setup. In Menu 2.1 Display readout / Optional sensor

Menu 2.1.3, the pressure sensor is chosen so the actual pressure can be seen.

Fan speed on TWIN

The Fan speed sensor can measure the revolutions on the blower unit on a TWIN sprayer.

The sensor is mounted on blower as shown in Picture 6.

For connecting the wiring from the Fan speed sensor see section “PCB’s” on pages 70.

Picture 6 Fan speed sensor

When the Fan speed sensor is mounted and the wires are connected, the HC5500 must be

setup for the sensor. In menu E5.2 the PPU value is set. The PPU value can be seen in the

menu E5.2.1. The default value is 1.

For a reading on the HC5500 display, the Fan speed sensor must be setup for the display.

In Menu 2.1, Display readout / Optional sensor, Menu 2.1.3, is the Fan speed sensor

chosen so the fan r/min can be seen.

Note the following for the Linak actuators on the TWIN FORCE sprayers

Spray II box &

Linak actuator AMP

connector Linak

Part no. Voltage

(min to max stroke) Signal

Breakout PCB 4 pin 262034 1.0 to 5.0 V Analogue

JobCom PCB 4 pin 262034 1.0 to 12.0 V PWM (Hz)

Page 15 of 87

TankGauge

The TankGauge (digital contents sensor) is a sensor that can measure how much liquid is in

the tank. It has no automatic function. It can give a warning when the tank is about to run

dry.

Connecting TankGauge

Wire between JobCom and 26007300

Figure 1 Wire for connection between JobCom and TankGauge

The cable is fitted with an AMP plug and three lose wires at the other end. It is attached to

the JobCom at J1, “Tank gauge”.

For JobCom with hardware version before 2.0, a 10Kohm resistor is fitted between

connector 2 & 3 on the JobCom.

Figure 2 shows the resistor location.

Figure 2 Mounting of the 10 K ohm resistance in the JobCom

Models without JobCom:

A. TankGauge is mounted on PCB in

distribution valves junction box.

Green/Grey wire is connected to the

blue wire from TankGauge.

B. Is mounted in OPT 1 as shown.

Brown wire +

Black wire –

If a speed sensor is present, connect

it in parallel.

Distribution Valves Junction Box

The cable from the Spray box has two lose wires which are not connected in the JobCom.

These much be attached to the plug as shown on Picture 7

AMP Super Seal PCB Wire Wire (old version)

2 + Brown Green

3 Sig Blue White

1 - Black Brown

- Signal +

Blue

wire

Black

wire Brown

wire

A B

Page 16 of 87

Picture 7 Connection of the two wires from Spray box cable

The sensor is mounted on the back side of the sump of the tank.

Settings in the HC5500

“Extended Menu 5 Optional sensors" is the setup menu. In Menu E5.3.1 chose “HARDI”.

To check the connections, the frequency with an empty tank can be checked.

Menu 4.5.3.3, Tank Gauge, should read be between 100 and 200 Hz.

How does it work?

The TankGauge sensor measures the pressure created by the water in the tank. The

sensor sets data points for each 25 mm of water level. 100 data points are available. The

data points are registration marks where the tank sensor registers the pressure and

therefore how much water there is left in the tank at this water level.

The data points can be seen in Menu E8.2.3. They can also be edited in this Menu.

For setting the data points, the flow sensor must first be calibrated.

Next step is to fill the tank completely with a known quantity of water.

When the calibration starts, the flow sensor will register how much water is sprayed out and

the tank sensor will register the pressure for every 25 mm water level until the tank is empty.

At the end of the calibration, the actual verses the theoretical quantity of water is set just like

doing a “Tank Method” calibration of the nozzles. This will fine tune the flow sensor PPU.

The calibration of the TankGauge is described in the instruction book.

When the TankGauge is used in use, there are two modes:

•When the sprayer is moving

•When the sprayer is stationary

When the sprayer is moving, the HC5500 will calculate an average value of the read out

from the TankGauge. The average value is necessary because of the movement of the

liquid in the tank will when the sprayer is moving. If a not averaged value was shown, the

readout would be useless for the driver.

When stationary, the value is not averaged. The movement of the liquid in the tank should

stop and the average value is therefore not necessary.

Left side = Green/Gray

Right side = Pink/Yellow

Page 17 of 87

End nozzle kit

The End nozzle kit is connected to the “PCB for section valves”, seen on page 71. For

accurate boom width whilst using the end nozzles, Menu 3.3.4 needs to be set up. For more

information, see in the instruction book for the HC5500.

Picture 8 End Nozzle kit

Page 18 of 87

Extended Menu for SW 4.XX

To access Extended Menu, press and hold the “ESC” button, switch the power ON and wait

until the menu is opened.

The “[xxx]” indicates the choices or range.

The factory default and helpful notes like increments of change are in italics.

Extended Menu 1 Language: Here the is language choice. There are standard languages

and place for two local languages that can be uploaded to the HC5500 by a service person.

Note: For Russian, the HC5500 hardware version with Cyrillic text is used.

Extended Menu 2 Unit: Is for what unit the controller shall use.

Extended Menu 3 Sprayer type: The basis setup of what kind of sprayer is the HC5500

attached to and what kind of liquid system is mounted on the sprayer.

Extended Menu 4 Data exchange: Setup of the data communication.

HC5500 can be attached to other units like a PC, printers, variable Rate Application or

remote control. The communication between the HC5500 and the unit has to be set up

correctly.

The setup and use of the com ports are described in the “Software” section of this manual.

Extended Menu 5 Optional sensors: Setup of optional sensors that can be fitted. It is

typically the pressure, fan revolutions and tank contents (TankGauge).

Extended Menu 6 Service interval: Setup of the service interval.

Extended Menu 7 Factory settings: Setup of factory settings

Extended Menu 8 Settings: Settings of the regulation, tank, track and misc. settings are

done.

Extended Menu 9 JobCom: Is for setup of the JobCom, TWIN actuators and read out of

the software version and serial number.

Extended Menu 1 Language

E1 Language [UK, D, DK, F, SF, HU, Local 1, Local 2]

Default is UK.

Local 1 & 2 are languages that can be added with a PC and the “HC 5500 Language config”

software or another HC5500.

Extended Menu 2 Unit

E2 Unit [Metric, US]

Page 19 of 87

Extended Menu 3 Sprayer type

E3.1 Field sprayer E3.1.1 Liquid system

[Equalization, Not equalization, Circulation]

Default is Equalization.

Equalization = System with liquid return to tank from

section valves; e.g. EVC.

Not equalization = System without returns to tank;

e.g. EFC on CM05.

Circulation = System where liquid constantly

circulates in the boom lines.

E3.1.2 Dual Line

E3.1.2.1 System type

[Not present, 2 stage, 3 stage]

Default is Not present.

2-stage: Line A will always be open, and Line B can

be switched on and off automatically.

3-stage: Line A switches to B, then Line A comes on

so both A & B are on.

E3 Sprayer

type E3.1.2.2 Sensor type

[Pressure, Speed]

If a pressure transducer is fitted, pressure is used to

trigger the line change.

E3.1.2.3 System lag

[Second]

Default is 1.0 sec.

System lag prevents oscillation when spray lines

change.

E3.1.2.4 Line overlap

[Second]

Default is 1.5 sec.

System overlap allows the activated spray line to

stabilise before the other line is turned off.

E3.2 Mistblower E3.2.1 Liquid system

[Equalization, Not equalization, Circulation]

Default is Equalization.

Equalization = System with liquid return to tank from

section valves; e.g. EVC.

Not equalization = System without returns to tank;

e.g. Solenoid controls.

Circulation = System where liquid constantly

circulates in the boom lines

E3.2.2 Sub unit

[Standard, UCR]

Default = Standard (UCR affects menu 3.3)

UCR = Unit Canopy Row. Bases application on the

size of the tree canopy.

Page 20 of 87

Extended Menu 4 Data exchange

E4.1 COM 1

setup E4.1.1 Equipment type

[Printer, Dump, Printer & dump, GSM,

VRA/remote]

Dump is for data transfer to a PC via for

example Microsoft HyperTerminal.

GSM is not used.

Variable Rate Application/remote is signal from

an external source.

E4 Data

exchange E4.1.2 Baud rate

[19200, 9600, 4800, 2400, 1200]

Default is 9600.

Use 9600 for HARDI 12 volt printer.

E4.1.3 Protocol select

[HARDI VRA proto.]

Only one protocol available at the moment.

E4.2 COM 2

setup E4.2.1 Equipment type

[Printer, Dump, Printer & dump, GSM,

VRA/remote]

Dump is for data transfer to a PC via for

example Microsoft HyperTerminal.

GSM is not used.

Variable Rate Application/remote is signal from

an external source.

E4.2.2 Baud rate

[19200, 9600, 4800, 2400, 1200]

Default is 9600.

Use 9600 for HARDI 12 volt printer.

E4.2.3 Protocol select

[HARDI VRA proto.]

Only one protocol available at the moment.

Other manuals for HC5500

6

Table of contents

Other Hardi Controllers manuals

Hardi

Hardi HC 5500 SPRAY BOX III User manual

Hardi

Hardi COMMANDER 5500 User manual

Hardi

Hardi HC5500 User manual

Hardi

Hardi HC 9600 User manual

Hardi

Hardi HC5500 User manual

Hardi

Hardi HC5500 User manual

Hardi

Hardi ISOBUS VT User manual

Hardi

Hardi HC 2500 Series User manual

Hardi

Hardi HC 8500 User manual

Hardi

Hardi HC5500 User manual