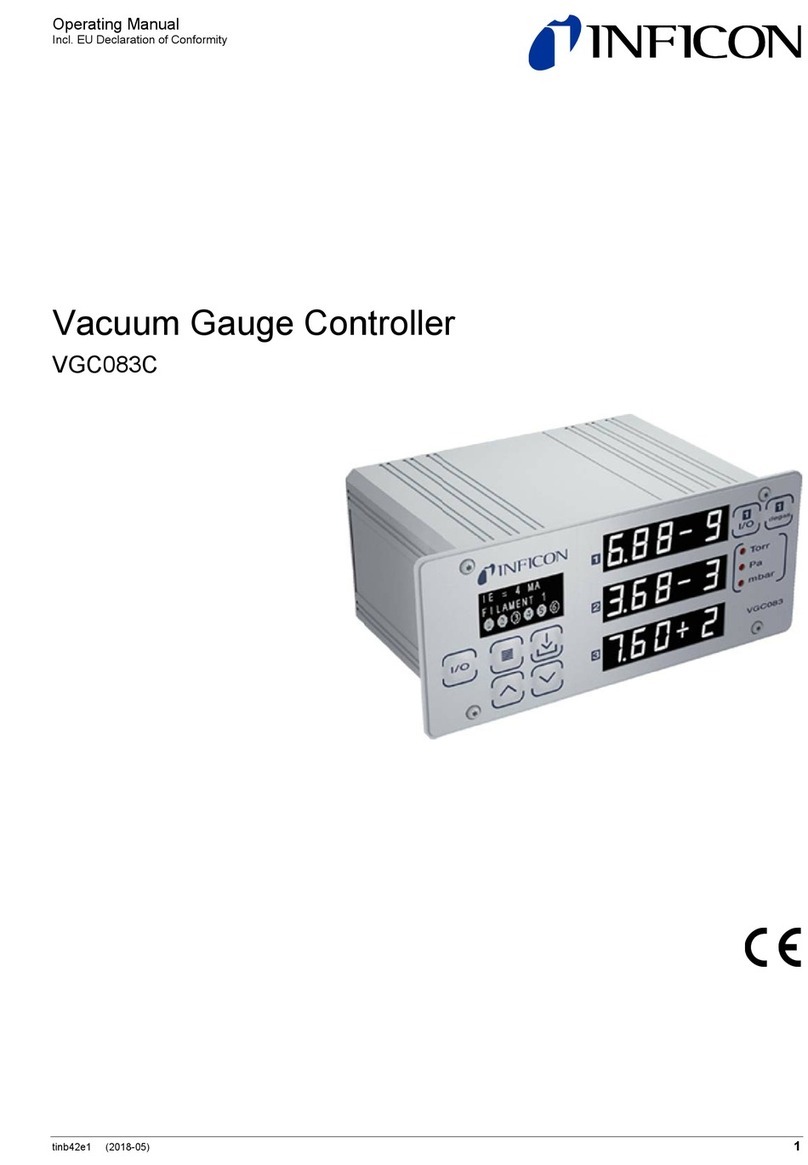

Inficon MAG050 User manual

Cold Cathode Gauge

MAG050

MAG060

Operating Manual

Incl. EU Declaration of Conformity

tinb43e1 (2018-06)

Product Identification

In all communications with INFICON, please specify the

information on the product nameplate. For convenient

reference copy that information into the space provided

below.

Validity

This document applies to products with part number

399-840 (MAG050, DN 25 ISO-KF)

399-841 (MAG050, DN 40 ISO-KF)

399-842 (MAG050, DN 40 CF-F)

399-845 (MAG060, DN 40 ISO-KF)

399-846 (MAG060, DN 40 CF-F)

The part number (PN) can be taken from the product name-

plate.

If not indicated otherwise in the legends, the illustrations in

this document correspond to the product with vacuum

connection DN 40 ISO-KF. They apply to the products with

other vacuum connections by analogy.

Intended Use

The above Cold Cathode Gauges have been designed for

vacuum measurement in the pressure range of

MAG050: 2×10-9 ... 5×10-3 hPa│mbar

MAG060: 1×10-10 ... 5×10-3 hPa│mbar.

They are used together with a INFICON measurement and

control unit of the type VGC083C.

Functional Principle

Over the whole measurement range, the measuring signal is

output as logarithm of the pressure.

The MAG050 / MAG060 function with a cold cathode ioniza-

tion measurement circuit (according to the inverted magne-

tron principle).

Safety

Symbols Used

Information on preventing any kind of physical injury.

Information on preventing extensive equipment and envi-

ronmental damage.

Information on correct handling or use. Disregard can lead

to malfunctions or minor equipment damage.

Note

Personnel Qualification

All work described in this document may only be carried

out by persons who have suitable technical training and the

necessary experience or who have been instructed by the

end-user of the product.

General Safety Instructions

•Adhere to the applicable regulations and take the neces-

sary precautions for the process media used.

•Consider possible reactions between the materials

(→Technical Data) and the process media.

•Consider possible reactions (e.g. explosion) of the pro-

cess media due to the heat generated by the product.

•Adhere to the applicable regulations and take the neces-

sary precautions for all work you are going to do and con-

sider the safety instructions in this document.

•Before beginning to work, find out whether any vacuum

components are contaminated. Adhere to the relevant

regulations and take the necessary precautions when

handling contaminated parts.

DANGER

DANGER: magnetic fields

Strong magnetic fields can disturb electronic

devices like heart pacemakers or impair their

function.

Maintain a safety distance of ≥10 cm between

the magnet and the heart pacemaker or prevent

the influence of strong magnetic fields by anti-

magnetic shielding.

Communicate the safety instructions to all other users.

Responsibility and Warranty

INFICON assumes no liability and the warranty becomes null

and void if the end-user or third parties

•disregard the information in this document

•use the product in a non-conforming manner

•make any kind of interventions (modifications, alterations,

etc.) on the product

•use the product with accessories not listed in the corre-

sponding product documentation.

The end-user assumes the responsibility in conjunction with

the process media used.

Gauge failures due to contamination are not covered by the

warranty.

Technical Data

Admissible temperatures

Storage

–40 °C … +80 °C

Operation

MAG050

+5 °C … +80 °C

(with normal cable)

+5 °C … +150 °C

(with high temperature cable)

MAG060 +5 °C … +80 °C

(with normal cable)

+5 °C … +250 °C

(with high temperature cable)

Bakeout

MAG050

+150 °C (without cable)

MAG060 +250 °C (without cable)

Relative humidity max. 80% at temperatures

up to +31 °C, decreasing to

50% at +40 °C

Use indoors only

altitude up to 2000 m NN

Measurement range (air, N2)

MAG050

2×10

-9

… 5×10

-3

hPa│mbar

MAG060 1×10-10 … 5×10-3 hPa│mbar

Accuracy (N2, typical)

30% of reading

Repeatability (typical) 5% of reading

Gas type dependence →Appendix

Protection type

IP 40

Overpressure ≤900 kPa (≤9 bar)

for inert gases and tempera-

tures <55 °C only

Radiation resistance

MAG050

–

MAG060

10

9

rad

Operating voltage

(in measuring chamber)

≤3.3 kV

Operating current

(in measuring chamber)

≤700 µA

Electrical connection

Connector

Type

SHV

coaxial cable

Cable length between gauge

and measurement unit

MAG050

max. 100 m

(40 m if the lower limit of the

measurement range is used

→[1], Operating Manual

VGC083C)

MAG060 max. 100 m

(6 m if the lower limit of the

measurement range is used,

→[1], Operating Manual

VGC083C)

Materials on the

vacuum side

Vacuum connection

Measuring chamber

DN 25 ISO-KF

DN 40 ISO-KF / CF-F

Feedthrough isolation

Internal seal MAG050

MAG060

Anode

Ignition aid

stainless steel (1.4306)

stainless steel (1.4104)

stainless steel (1.4306)

ceramic (Al2O3)

FPM

Ag

Mo

stainless steel (1.4310)

Internal volume ≈20 cm³

Dimensions [mm]

Weight 600 g (DN 25 ISO-KF, DN 40 ISO-KF)

850 g (DN 40 CF-F)

Installation

Vacuum Connection

DANGER

Overpressure in the vacuum system >100 kPa

(>1 bar)

Injury caused by released parts and harm

caused by escaping process gases can result if

clamps are opened while the vacuum system is

pressurized.

Do not open any clamps while the vacuum sys-

tem is pressurized. Use the type clamps which

are suited to overpressure.

DANGER

Overpressure in the vacuum system >250 kPa

(>2.5 bar)

KF connections with elastomer seals (e.g.

O-rings) cannot withstand such pressures. Pro-

cess media can thus leak and possibly damage

your health.

Use O-rings provided with an outer centering

ring.

DANGER

Protective ground

Incorrectly grounded products can be extremely

hazardous in the event of a fault.

The gauge must be electrically connected to the

grounded vacuum chamber. This connection

must conform to the requirements of a protective

connection according to EN 61010:

•CF connections fulfill this requirement

•For gauges with a KF flange, use a conduc-

tive metallic clamping ring

Caution

Vacuum component

Dirt and damages impair the function of the

vacuum component.

When handling vacuum components, take ap-

propriate measures to ensure cleanliness and

prevent damages.

Caution

Dirt sensitive area

Touching the product or parts thereof with bare

hands increases the desorption rate.

Always wear clean, lint-free gloves and use

clean tools when working in this area.

When CF vacuum connections are made, it can be advanta-

geous to temporarily remove the magnet unit (→Removing

the Magnet Unit).

Mount the gauge so that no vibrations occur. Vibrations at

the gauge cause a deviation of the measured values.

The gauge may be mounted in any orientation.

To keep condensates and particles from getting into

the measuring chamber preferably choose a hori-

zontal to upright position.

Remove the protective lid and connect the product to the

vacuum system.

Keep the protective lid.

Removing the Magnet Unit

(CF vacuum connection only)

For reasons of tolerance, the same magnet unit has

to be used again when reassembling the gauge.

Tools Required

•Allen wrench AF 1.5

•Open-end wrench AF 7

Procedure

Unfasten the hex head screw (3) on the magnet unit (4)

and remove the magnet unit.

The magnetic force and the tendency to tilt

make it more difficult to separate the magnet

unit and the measuring chamber (7).

Make the vacuum connection between the gauge and

the vacuum system.

Mount the magnet unit and lock it with the hex head

screw (3).

Electrical Connection

•Make sure the vacuum connection is properly

made.

•The VGC083C control unit must be turned off

before any work is performed on the gauge or

sensor cable.

Connect the sensor cable to the gauge and to the INFICON

measurement unit.

Operation

The gauge is ready for operation as soon as it has been

connected.

Gas type Dependence

The measuring signal depends on the type of gas being

measured. The value displayed is accurate for dry air, N2, O2

and CO. It can be mathematically converted for other gases.

This can be done by entering the corresponding calibration

factor on the INFICON measurement unit (→Appendix).

Ignition Delay

When cold cathode measurement systems are activated, an

ignition delay occurs. The delay time increases at low pres-

sures and for clean, degassed gauges it is typically:

1×10-7 hPa│mbar ≈0.1 minute

1×10-8 hPa│mbar ≈1 minute

1×10-9 hPa│mbar ≈5 minutes

1×10-10 hPa│mbar ≈20 minutes (MAG060 only)

The ignition is a statistical process. Already a small amount

of depositions on the inner surfaces can have a strong in-

fluence on it.

Contamination

Gauge failures due to contamination are not covered by the

warranty.

Cold cathode gauges are subject to contamination. The de-

gree of contamination and subsequently the accuracy of the

measured value depend on:

•the pressure in the vacuum chamber

•contaminants inside the vacuum chamber (vapors, pro-

cess particles, etc.)

•the measurement current.

To avoid extensive contamination switch the gauge

on only at pressures of <10-2 hPa│mbar.

Contamination generally has the effect that the pressure indi-

cation is too low. If the contamination is severe, instability

occurs. Contamination layers can peel off in the measuring

chamber and cause short circuits.

Depending on the operating conditions, cleaning may there-

fore be necessary after a few days or after a few years.

Deinstallation

Contaminated parts

Contaminated parts can be detrimental to health

and environment.

Before beginning to work, find out whether any

parts are contaminated. Adhere to the relevant

regulations and take the necessary precautions

when handling contaminated parts.

Caution

Vacuum component

Dirt and damages impair the function of the

vacuum component.

When handling vacuum components, take ap-

propriate measures to ensure cleanliness and

prevent damages.

Caution

Dirt sensitive area

Touching the product or parts thereof with bare

hands increases the desorption rate.

Always wear clean, lint-free gloves and use

clean tools when working in this area.

Procedure

Turn off the VGC083C control unit.

Vent the vacuum system and disconnect the sensor

cable from the gauge.

Remove gauge from the vacuum system and install the

protective lid.

Maintenance

Sensor failures due to contamination are not covered by the

warranty.

Cleaning the Gauge / Changing Parts

Contaminated parts

Contaminated parts can be detrimental to health

and environment.

Before beginning to work, find out whether any

parts are contaminated. Adhere to the relevant

regulations and take the necessary precautions

when handling contaminated parts.

Model:

PN:

SN:

INFICON AG, LI-9496 Balzers

ø63.5

92

97.5

DN 40 CF-F

DN 25 ISO-KF

DN 40 ISO-KF

AF 7

Vacuum

chamber

4

3

7

Original: English

t i nb43e1

Caution

Vacuum component

Dirt and damages impair the function of the

vacuum component.

When handling vacuum components, take ap-

propriate measures to ensure cleanliness and

prevent damages.

Caution

Dirt sensitive area

Touching the product or parts thereof with bare

hands increases the desorption rate.

Always wear clean, lint-free gloves and use

clean tools when working in this area.

Precondition

•Gauge removed from vacuum system

Tools required

•Allen wrench AF 3

•Open-end wrench AF 7

•Pliers for circlip

•Polishing cloth (grain 400) or Scotch-Brite

•Tweezers

•Mounting tool for ignition aid

•Cleaning alcohol

Disassembling the Gauge

(MAG050 →Figure 1, MAG060 →Figure 2)

Precondition

•Gauge removed from vacuum system

Procedure

Unfasten the hex head screw (3) on the magnet unit (4)

and remove the magnet unit.

The magnetic force and the tendency to tilt

make it more difficult to separate the magnet

unit and the measuring chamber (7).

For reasons of tolerance, the same magnet

unit has to be used again when reassembling

the gauge.

Remove the circlip (5) and the pole insert (6) from the

measuring chamber (7).

Loosen the 2 hex socket screws (1a) and remove the

coaxial connector (2a).

Remove the 4 (or 2) hex socket screws (8) incl. the

lock washers (8a) on the back of the measuring cham-

ber (7).

MAG050: Carefully remove the following items in this

order: pressure piece (9), complete anode (10), inner

ring (11) and FPM seal (12).

MAG060: Carefully remove the following items in this

order: pressure piece (9), washer (10b), complete

anode (10), metal seal (11) and centering ring (12).

The parts can now be cleaned or replaced individually

(→next section).

Cleaning the Gauge

Procedure

DANGER

Adhere to the relevant regulations and take the necessary

precautions when handling and disposing of cleaning

agents.

Cleaning the measuring chamber and the pole insert:

Clean the inside walls of the measuring chamber and

the pole insert to a bright finish. Use a polishing cloth.

Caution

Sealing surfaces must only be worked concentrically.

Rinse the measuring chamber and the pole insert with

alcohol.

Dry both.

Cleaning or replacing the anode (10):

Remove the old ignition aid (10a), for example with

tweezers.

Rub the anode pin to a bright finish by means of a

polishing cloth.

Caution

Do not bend the anode.

Do not carry out mechanical work on the ceramic

part.

Rinse the anode with cleaning alcohol.

Dry the anode.

Insert the new ignition aid (10a) into the mounting tool.

Carefully press the anode (cleaned or new) centered

and parallel to the tool axis into the ignition aid and in-

sert it to a depth of ≈15 mm. The final position is estab-

lished only after the anode is installed.

Assembling the Gauge

Procedure

MAG050: Insert the FPM seal (12) with the inner

ring (11) centered into the measuring chamber (7).

Sealing surface, seal and ceramic part must be clean

(→figure 1).

MAG060: Insert new metal seal (11) with the centering

ring (12) centered into the measuring chamber (7).

Sealing surface, seal and ceramic part must be clean

(→figure 2).

Carefully insert the anode (10) incl. ignition aid (10a)

into the measuring chamber.

Place the pressure piece (9) incl. Washer (10b) on the

measuring chamber (7) and tighten the screws (8) incl.

lock washers (8a) uniformly until the stop position is

reached.

Position the ignition aid (10a): slide the mounting tool

over the anode pin until the mechanical stop is

reached.

Remove particles in the measuring chamber (7) by

blowing with dry nitrogen (while the flange of the

measuring chamber is pointing downward).

Slide the pole insert (6) into the measuring chamber (7)

up to the mechanical stop (MAG050 →Figure 1,

MAG060 →Figure 2).

Place the circlip (5) snugly fitting on the pole insert.

Visually check that the anode pin is centered

over the hole of the pole insert (tolerated ec-

centricity ≤0.5 mm).

If possible perform a leak test

(leak rate <10-9hPa l/s│mbar l/s).

Place the coaxial connector (2a) on the measuring

chamber and tighten both hex socket screws (1a).

Mount the magnet unit (4) and lock it with the

screw (3).

Figure 1: MAG050

Figure 2: MAG060

Troubleshooting

Problem

Possible cause

Correction

The measurement

values indicated

are too low

Gauge contaminated

Clean the gauge

Spare Parts / Accessories

When ordering spare parts, always indicate:

•all information on the nameplate

•description and ordering number according to spare parts

list

MAG050 Position

→figure 1 Ordering

number

Maintenance kit

Inner ring

O-ring FPM, 3.69×1.78

O-ring FPM, 10.82×1.78

Ignition aid

(11)

— 1)

(12)

(10a)

BN 846 239-T

Repair kit

O-ring FPM, 10.82×1.78

Anode complete

Inner ring

Ignition aid

(12)

(10)

(11)

(10a)

BN 846 252-T

1) O-ring not used.

MAG060 Position

→

figure 2

Ordering

number

Maintenance kit

Metal seal, HNV100 9×1.6

Centering ring

Ignition aid

Washer

(11)

(12)

(10a)

(10b)

BN 846 241-T

Repair kit

Anode complete

Washer

Metal seal, HNV100 9×1.6

Centering ring

Ignition aid

(10)

(10b)

(11)

(12)

(10a)

BN 846 240-T

Returning the Product

Forwarding contaminated products

Contaminated products (e.g. radioactive, toxic,

caustic or microbiological hazard) can be detri-

mental to health and environment.

Products returned to INFICON should preferably

be free of harmful substances. Adhere to the

forwarding regulations of all involved countries

and forwarding companies and enclose a duly

completed declaration of contamination (form

under www.inficon.com).

Products that are not clearly declared as "free of harmful

substances" are decontaminated at the expense of the

customer.

Products not accompanied by a duly completed declaration

of contamination are returned to the sender at his own ex-

pense.

Disposal

Contaminated parts

Contaminated parts can be detrimental to health

and environment.

Before beginning to work, find out whether any

parts are contaminated. Adhere to the relevant

regulations and take the necessary precautions

when handling contaminated parts.

Substances detrimental to the environment

Products or parts thereof (mechanical and elec-

tric components, operating fluids etc.) can be de-

trimental to the environment.

Dispose of such substances in accordance with

the relevant local regulations.

Separating the components

After disassembling the product, separate its components

according to the following criteria:

•Contaminated components

Contaminated components (radioactive, toxic, caustic, or

biological hazard etc.) must be decontaminated in accord-

ance with the relevant national regulations, separated

according to their materials, and recycled.

•Other components

Such components must be separated according to their

materials and recycled.

Appendix

Gas Type Dependence

Indicated pressure (gauge calibrated for air)

In the range below 10-5hPa│mbar the pressure indication is

linear. For gases other than air the pressure can be deter-

mined by means of a simple conversion formula:

peff = C × displayed pressure

where

Gas type

C

Air (N2, O2,CO)

1.0

Xe

0.4

Kr

0.5

Ar 0.8

H2

2.4

Ne 4.1

He

5.9

These conversion factors are average values.

A mixture of gases and vapors is often involved. In

this case accurate determination is only possible

with a partial pressure measuring instrument, e.g.

an INFICON quadrupole mass spectrometer.

Literature

[1] www.inficon.com

Operating Manual

VGC083C

tinb42e1

INFICON AG, LI-0496 Balzers, Liechtenstein

EU Declaration of Conformity

We, INFICON, hereby declare that the equip-

ment mentioned below comply with the pro-

visions of the following directives:

•2014/30/EU, OJ L 96/79, 29.3.2014

(EMC Directive; directive relating to electro-

magnetic compatibility)

•2011/65/EU, OJ L 174/88, 1.7.2011

(RoHS Directive; directive on the restriction of

the use of certain hazardous substances in

electrical and electronic equipment)

Products

Cold Cathode Gauge

MAG050

MAG060

(operation with VGC083C)

Standards

Harmonized and international/national standards and specifi-

cations:

•EN 61000-6-2:2005

(EMC: generic immunity standard)

•EN 61000-6-4:2007 + A1:2011

(EMC: generic emission standard)

•EN 61010-1:2010

(Safety requirements for electrical equipment for measure-

ment, control and laboratory use)

•EN 61326-1:2013; Group 1, Class A

(EMC requirements for electrical equipment for measure-

ment, control and laboratory use)

Manufacturer / Signatures

INFICON AG, Alte Landstraße 6, LI-9496 Balzers

15 June 2018

15 June 2018

Dr. Bernhard Andreaus

Director Product Evolution Markus Truniger

Product Manager

10 9

8

7

8a

10a

11

12

3

5

1a

42a

7

6

10

9

8

8a

10a

11

12

7

10b

3

5

1a

42a

7

6

LI–9496 Balzers

Liechtenstein

Tel +423 / 388 3111

Fax +423 / 388 3700

www.inficon.com

This manual suits for next models

1

Other Inficon Controllers manuals

Inficon

Inficon TPG300 User manual

Inficon

Inficon CU1000 User manual

Inficon

Inficon VGC031 User manual

Inficon

Inficon Cygnus 2 User manual

Inficon

Inficon Protec P3000 Operational manual

Inficon

Inficon VGC083C User manual

Inficon

Inficon VGC083A User manual

Inficon

Inficon VGC083B User manual

Inficon

Inficon IC6 User manual

Inficon

Inficon SQC-310 User manual

Popular Controllers manuals by other brands

ZPA Pečky

ZPA Pečky MODACT MTN 15 Mounting instructions

Regin

Regin RVAN10-24 Instruction

IR Ingersoll Rand

IR Ingersoll Rand ARO user manual

Siemens

Siemens SIMATIC S7-1500R/H manual

Mitsubishi Electric

Mitsubishi Electric MELSERVO-JET MR-JET-G Series user manual

Brooks Instrument

Brooks Instrument 5850EM Installation and operation manual