Harken equipment is designed for minimal maintenance, but some maintenance

is required to give the best service and to comply with the Harken limited warranty.

Cleaning: Flush blocks and loops/high strength lashing lines thoroughly with fresh

water. Periodically, disassemble the blocks and clean with detergent and fresh water.

When assembling block, make sure screws and holes are dry. Use blue Loctite®to

secure screw before assembling.

Important: Exposure to some teak cleaners and other caustic solutions can result

in discoloration of part and is not covered under the Harken warranty.

Printed in USA. 4641 04-12

Warranty

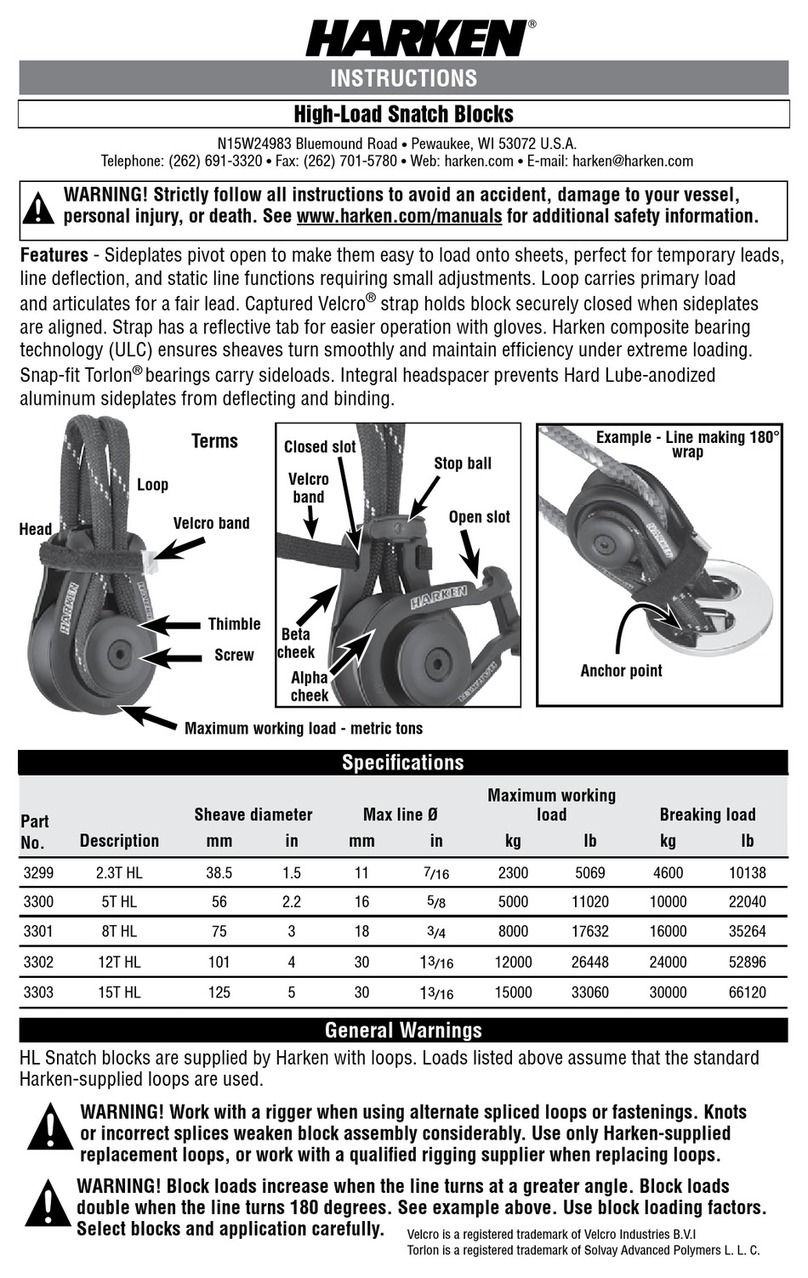

Inspect Parts Every Time you Sail

1. Inspect block to make

sure that screw is secure.

If screw is loose, remove

it, use blue Loctite®to hold

it in place and retighten.

2. Inspect sideplates to

make sure they are parallel

to each other. If they are

angled dead-end post may

not be seated. Take block

apart, install bail correctly

and secure with screw and

blue Loctite®.

3. Inspect loops and lashings. Replace if there are signs of wear or if the

colored tracer fades from UV damage.Pull loop out of mouth and inspect

loop/lashing carefully for any signs of wear, UV-damage, fatigue or strand

separation. Replace loop if it shows signs of UV-damage or wear.

4. Inspect lashing at head

of block to make sure knot

is holding tightly.

For additional safety, maintenance and warranty information see www.harken.com/

manuals or the Harken®catalog.

ALL INSTALLATIONS

Anchor Point Chafing or Cutting

Loops must be attached to round bails such as those found on padeyes

or pins. Sharp edges on many perforated toerails will cut loop, severely

weakening it. When loop is attached to a plate, it must be at least 1/4"

thick and have rounded edges to keep loop from being damaged.

Sharp edges will

damage loop

Round edges to prevent

damage to loop

WARNING! Failure to inspect and correct block and loop or

lashing may result in block breaking under load. Inspect parts

each time you sail. If parts are under load during long passages

it is important to inspect them carefully while in use.

WARNING! Loops or lashings running over a sharp edge can cause

part to break under load. Attach to fitting with a rounded edge.

WARNING! Failure to replace damaged or weakened parts can

cause part to break under load. Replace all loops and lashings

every year or if there is any sign of wear, UV damage, fatigue

or strand separation. If in doubt replace. Consult chart to match

strength of loop/lashing to block and load.

Maintenance

WARNING! Using a loop in a choker style weakens the loop

connection. Do not use choker style connection.