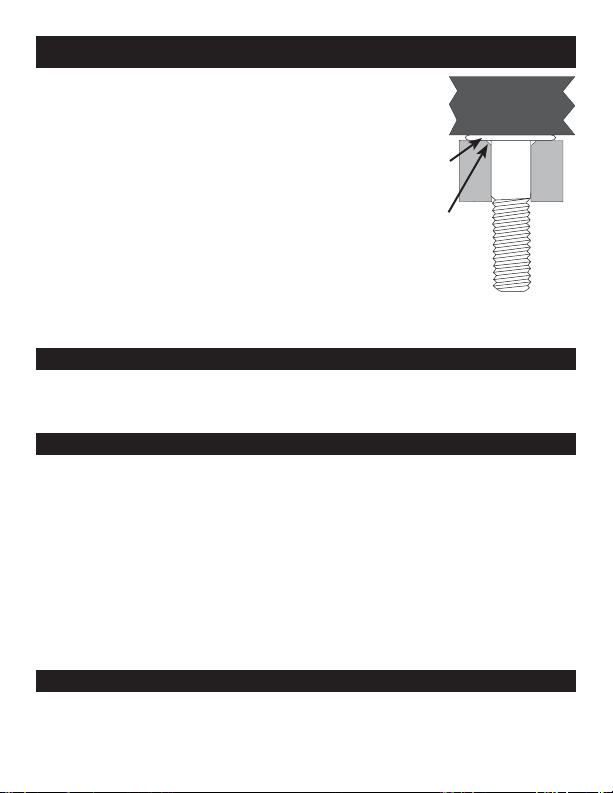

(see note) on bolt slides and slip into groove in bottom

of track. Note: When using 6mm bolts, slip provided metric

spacer under each bolt head before slipping into groove.

Apply high-quality bedding compound to mounting

surface around each hole then place stainless steel

washer over center of each hole.

Place bolts into holes and lower track. Bolt securely

using lock washers or locknuts. Most mounting

surfaces will require a backing plate for proper strength.

Mounting Track Continued

HFS1012

Washer

Bevel hole

slightly

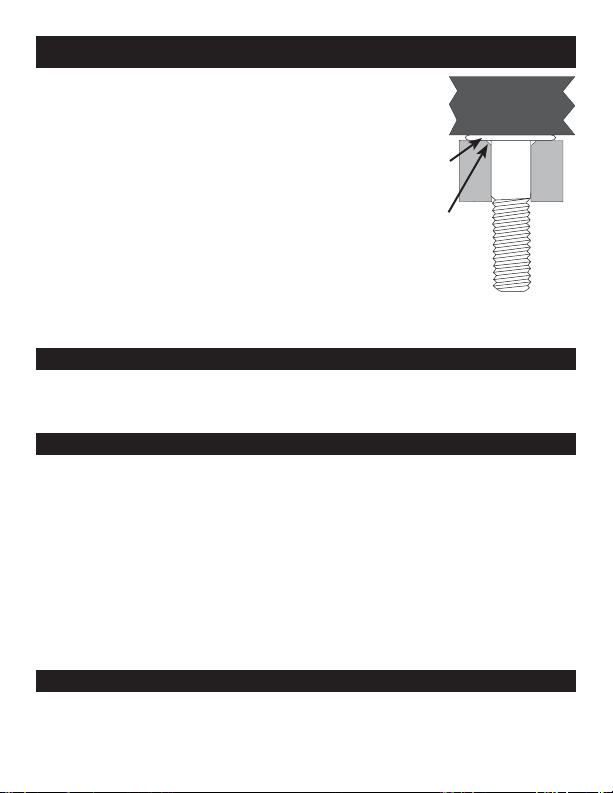

(see note) on bolt slides and slip into groove in bottom

of track. Note: When using 6mm bolts, slip provided metric

spacer under each bolt head before slipping into groove.

Apply high-quality bedding compound to mounting

surface around each hole then place stainless steel

washer over center of each hole.

Place bolts into holes and lower track. Bolt securely

using lock washers or locknuts. Most mounting

surfaces will require a backing plate for proper strength.

Mounting Track Continued

HFS1012

Washer

Bevel hole

slightly

(see note) on bolt slides and slip into groove in bottom

of track. Note: When using 6mm bolts, slip provided metric

spacer under each bolt head before slipping into groove.

Apply high-quality bedding compound to mounting

surface around each hole then place stainless

steel washer over center of each hole.

Place bolts into holes and lower track. Bolt securely

using lock washers or locknuts. Most mounting

surfaces will require a backing plate for proper strength.

Mounting Track Continued

HFS1012

Washer

Bevel hole

slightly

(see note) on bolt slides and slip into groove in bottom

of track. Note: When using 6mm bolts, slip provided metric

spacer under each bolt head before slipping into groove.

Apply high-quality bedding compound to mounting

surface around each hole then place stainless

steel

washer over center of each hole.

Place bolts into holes and lower track. Bolt securely

using lock washers or locknuts. Most mounting

surfaces will require a backing plate for proper strength.

Mounting Track Continued

HFS1012

Washer

Bevel hole

slightly

Printed in USA 4513 11/13

Traveler Cars: Clean by frequently flushing with fresh water. Periodically clean car by

squirting a detergent/water solution into center openings. Roll car back and forth to

distribute evenly then flush bearings with fresh water.

Do not use spray lubricants because ball bearings may skid not roll. Apply one to two

drops of McLube®OneDrop™to ball contact surfaces of track. Roll car back and forth

through OneDrop™several times to distribute onto bearings. Wipe remaining OneDrop™

off track. OneDrop™is preferred but you can also use one to two drops of a light

machine oil.

Track: Clean with detergent and water.

Important! Exposure to some teak cleaners and other caustic solutions can result in

discoloration of part and is not covered under the Harken warranty.

For additional safety, maintenance and warranty information see www.harken.com/

manuals or the Harken®catalog.

Maintenance

Warranty

Inspect

Frequently inspect shackles and control block fittings for signs of fatigue and replace as

necessary. Make sure every installation includes Harken track end stops. Arrange control

tackle so cars do not hit end stops under load.

Printed in USA 4513 11/13

Traveler Cars: Clean by frequently flushing with fresh water. Periodically clean car by

squirting a detergent/water solution into center openings. Roll car back and forth to

distribute evenly then flush bearings with fresh water.

Do not use spray lubricants because ball bearings may skid not roll. Apply one to two

drops of McLube®OneDrop™to ball contact surfaces of track. Roll car back and forth

through OneDrop™several times to distribute onto bearings. Wipe remaining OneDrop™

off track. OneDrop™is preferred but you can also use one to two drops of a light

machine oil.

Track: Clean with detergent and water.

Important! Exposure to some teak cleaners and other caustic solutions can result in

discoloration of part and is not covered under the Harken warranty.

For additional safety, maintenance and warranty information see www.harken.com/

manuals or the Harken®catalog.

Maintenance

Warranty

Inspect

Frequently inspect shackles and control block fittings for signs of fatigue and replace as

necessary. Make sure every installation includes Harken track end stops. Arrange control

tackle so cars do not hit end stops under load.

Printed in USA 4513 11/13

Traveler Cars: Clean by frequently flushing with fresh water. Periodically clean car by

squirting a detergent/water solution into center openings. Roll car back and forth to

distribute evenly then flush bearings with fresh water.

Do not use spray lubricants because ball bearings may skid not roll. Apply one to two

drops of McLube®OneDrop™to ball contact surfaces of track. Roll car back and forth

through OneDrop™several times to distribute onto bearings. Wipe remaining OneDrop™

off track. OneDrop™is preferred but you can also use one to two drops of a light

machine oil.

Track: Clean with detergent and water.

Important! Exposure to some teak cleaners and other caustic solutions can result in

discoloration of part and is not covered under the Harken warranty.

For additional safety, maintenance and warranty information see www.harken.com/

manuals or the Harken®catalog.

Maintenance

Warranty

Inspect

Frequently inspect shackles and control block fittings for signs of fatigue and replace as

necessary. Make sure every installation includes Harken track end stops. Arrange control

tackle so cars do not hit end stops under load.

Printed in USA 4513 11/13

Traveler Cars: Clean by frequently flushing with fresh water. Periodically clean car by

squirting a detergent/water solution into center openings. Roll car back and forth to

distribute evenly then flush bearings with fresh water.

Do not use spray lubricants because ball bearings may skid not roll. Apply one to two

drops of McLube®OneDrop™to ball contact surfaces of track. Roll car back and forth

through OneDrop™several times to distribute onto bearings. Wipe remaining OneDrop™

off track. OneDrop™is preferred but you can also use one to two drops of a light

machine oil.

Track: Clean with detergent and water.

Important! Exposure to some teak cleaners and other caustic solutions can result in

discoloration of part and is not covered under the Harken warranty.

For additional safety, maintenance and warranty information see www.harken.com/

manuals or the Harken®catalog.

Maintenance

Warranty

Inspect

Frequently inspect shackles and control block fittings for signs of fatigue and replace as

necessary. Make sure every installation includes Harken track end stops. Arrange control

tackle so cars do not hit end stops under load.