Harken 44.2STE Manual

Other Harken Winch manuals

Harken

Harken Performa 50.2 STP Manual

Harken

Harken Riggers Winch 200 User manual

Harken

Harken 35.2 PT Manual

Harken

Harken Performa Winch 40.2 PTP Manual

Harken

Harken Performa Winch 80.2 STP Manual

Harken

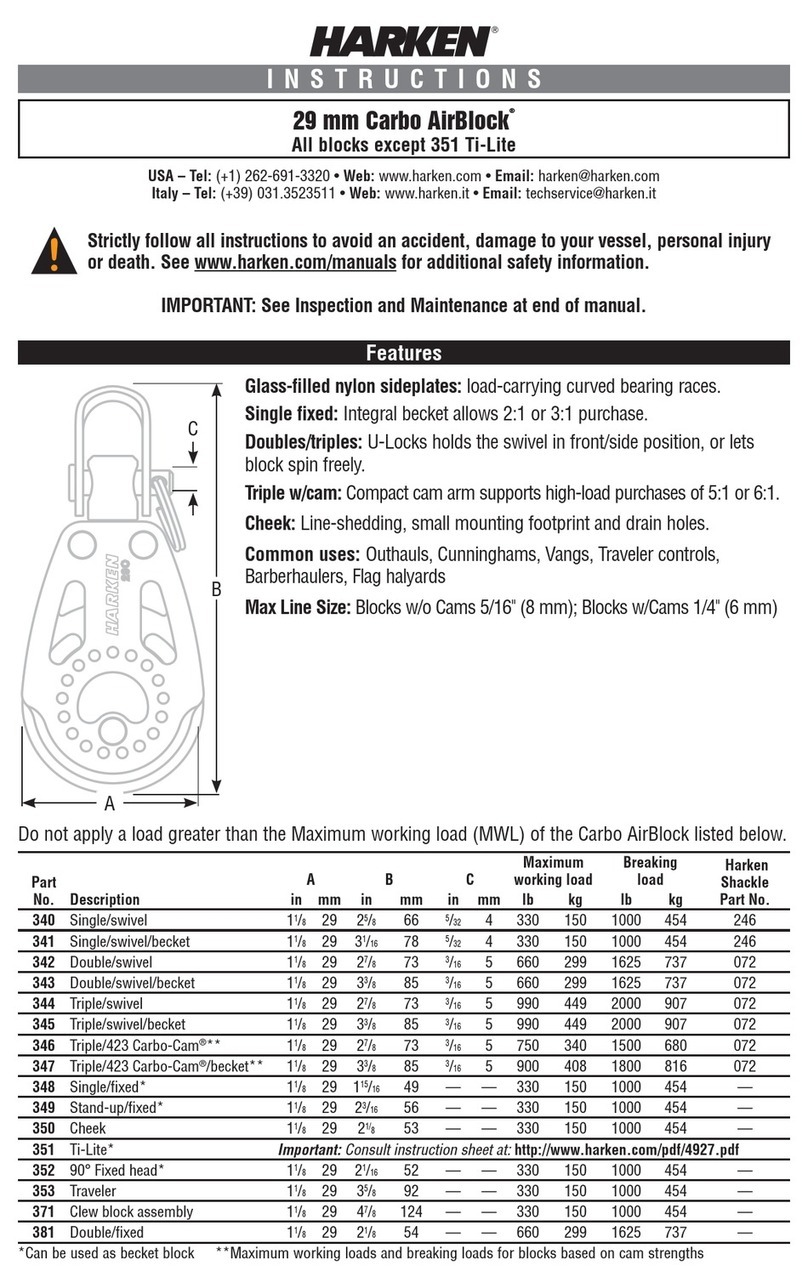

Harken Carbo AirBlock 340 User manual

Harken

Harken 46.2 ST EL Manual

Harken

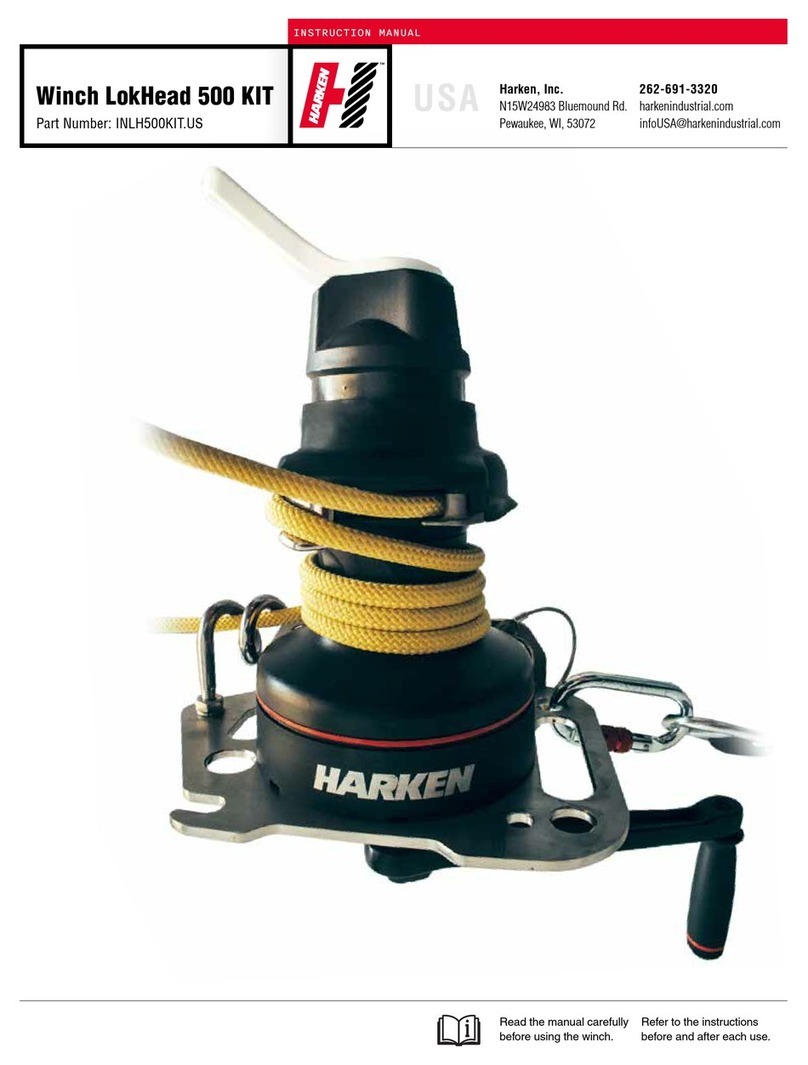

Harken INLH500KIT.US User manual

Harken

Harken Performa 60.2 STP EL/HY Manual

Harken

Harken 46.2 Quick start guide

Harken

Harken Powered Performa 80.3 STP EL/HY Manual

Harken

Harken 16st Manual

Harken

Harken LokHead 500 KIT.US User manual

Harken

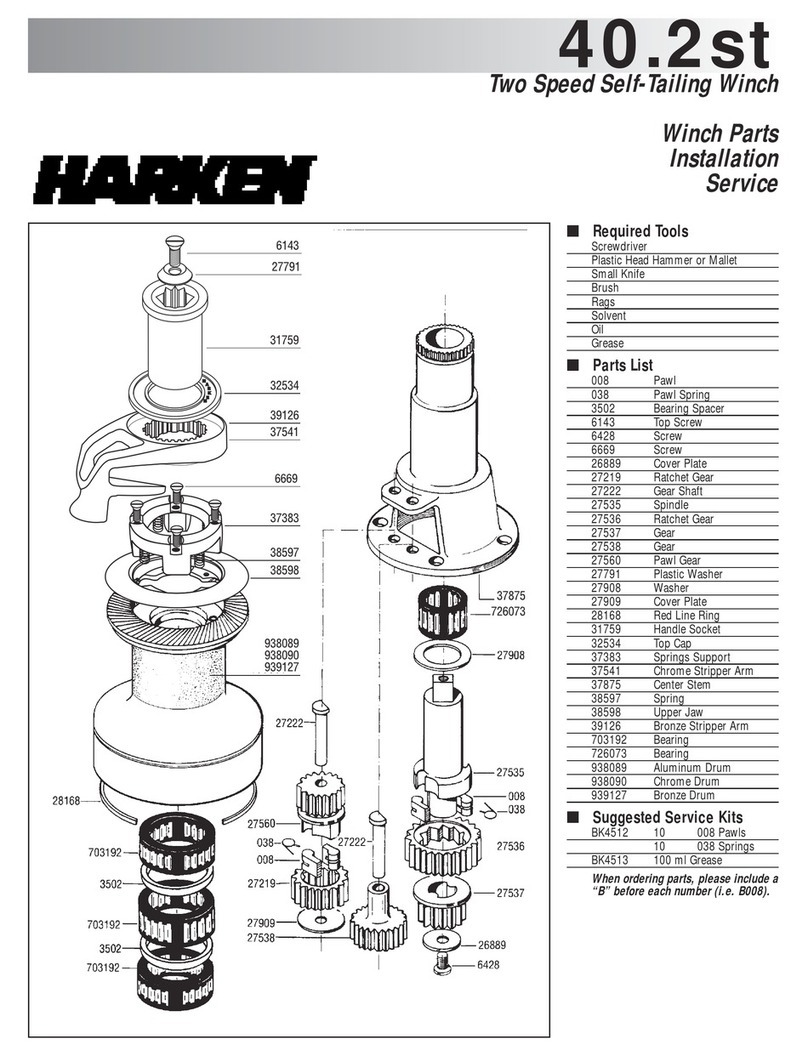

Harken 40.2ST E User manual

Harken

Harken Powered Performa Winch 70.2 STP EL Manual

Harken

Harken Performa Winch 70.3 STP Manual

Harken

Harken Carbon User manual

Harken

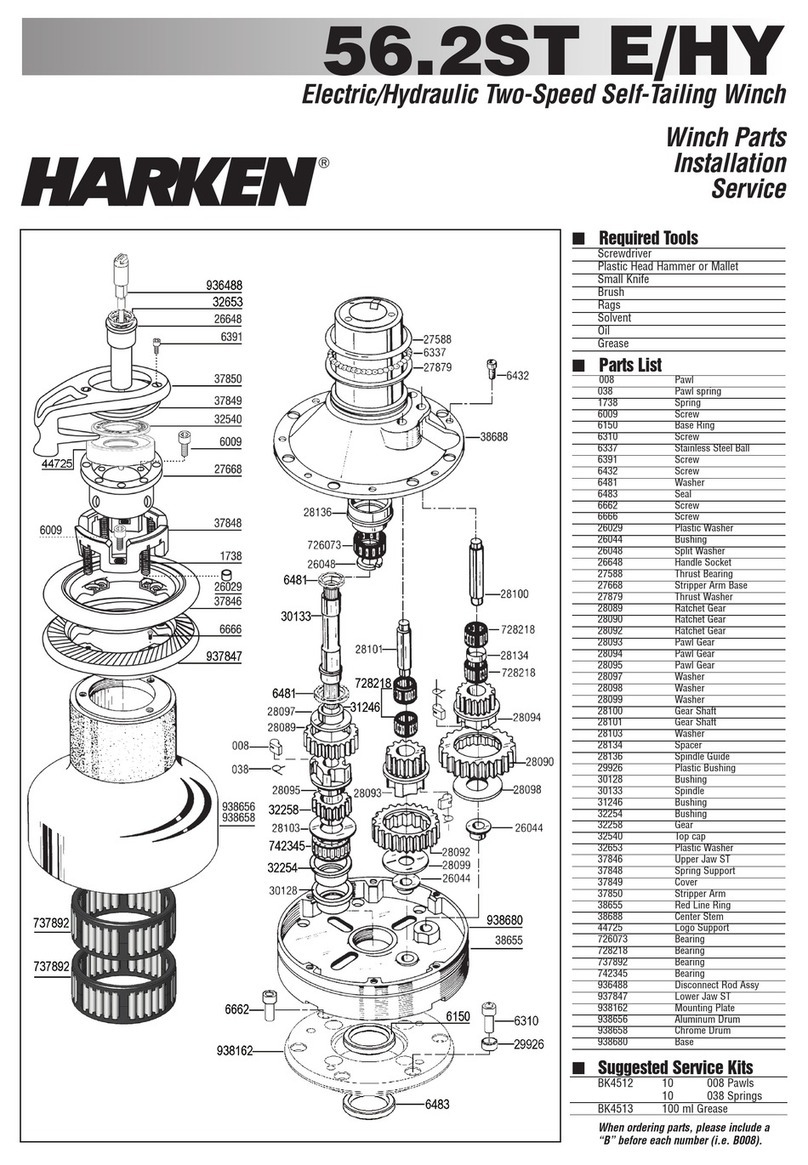

Harken 56.2ST E/HY User manual

Harken

Harken 40.2 ST EL Series Manual

Harken

Harken Radial Winch 40.2 PT BBB Manual

Popular Winch manuals by other brands

Topex

Topex 97X080 Instructions for use

Eastbound

Eastbound MotoWinch 1707001 operating instructions

Runva

Runva EWD8000 Assembly & operating instructions

Ingersoll-Rand

Ingersoll-Rand LIFTSTAR FG 1500/CN Series Parts, operation and maintenance manual

Granit

Granit 11157675 operating instructions

TREX

TREX TB75 user manual