HARTING ix Industrial 09 45 800 0181 User manual

Other HARTING Crimping Tools manuals

HARTING

HARTING T1 User manual

HARTING

HARTING 09 99 000 0196 User manual

HARTING

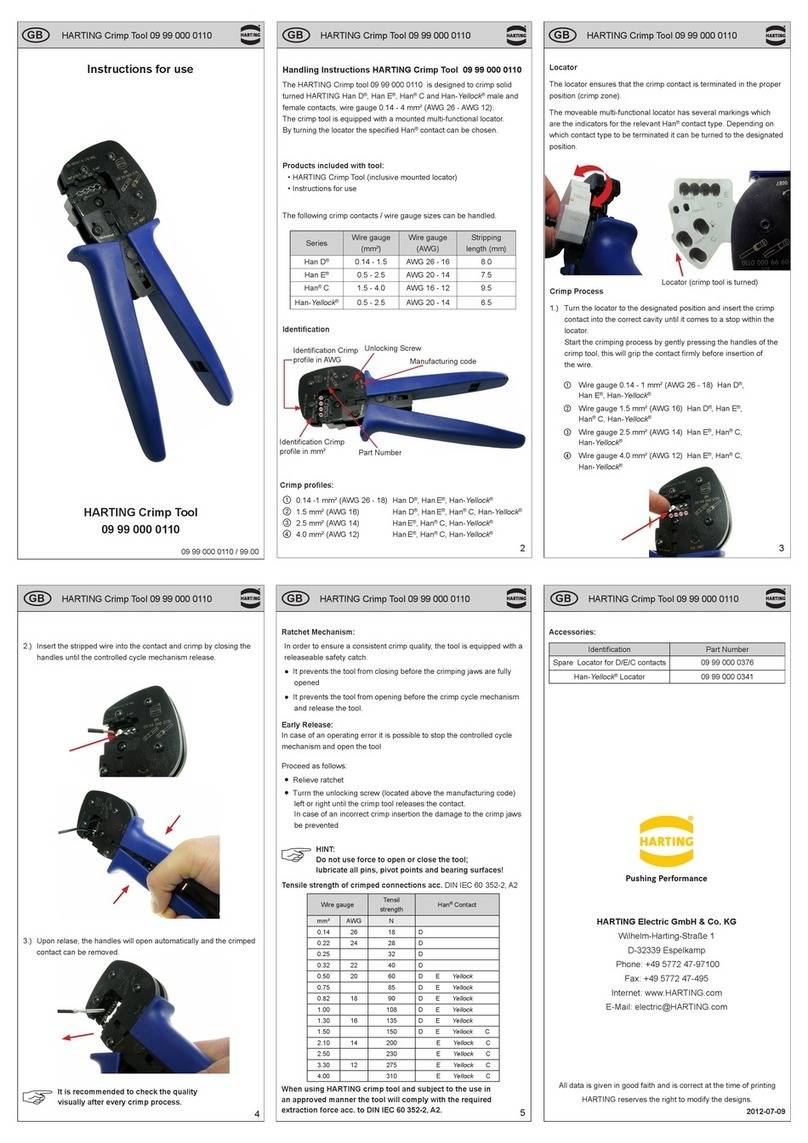

HARTING 09 99 000 0110 User manual

HARTING

HARTING 09990000695 User manual

HARTING

HARTING 09 99 000 0990 User manual

HARTING

HARTING 20 99 000 1035 User manual

HARTING

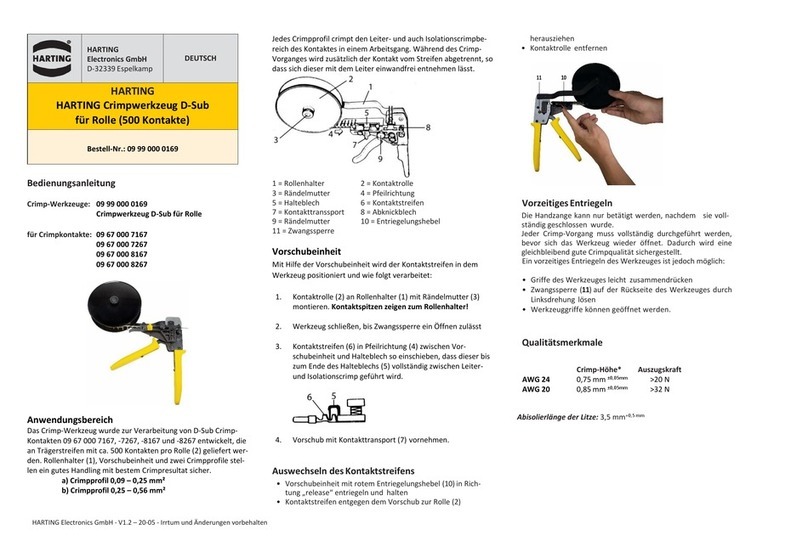

HARTING 09 99 000 0169 User manual

HARTING

HARTING 09 99 000 0656 User manual

HARTING

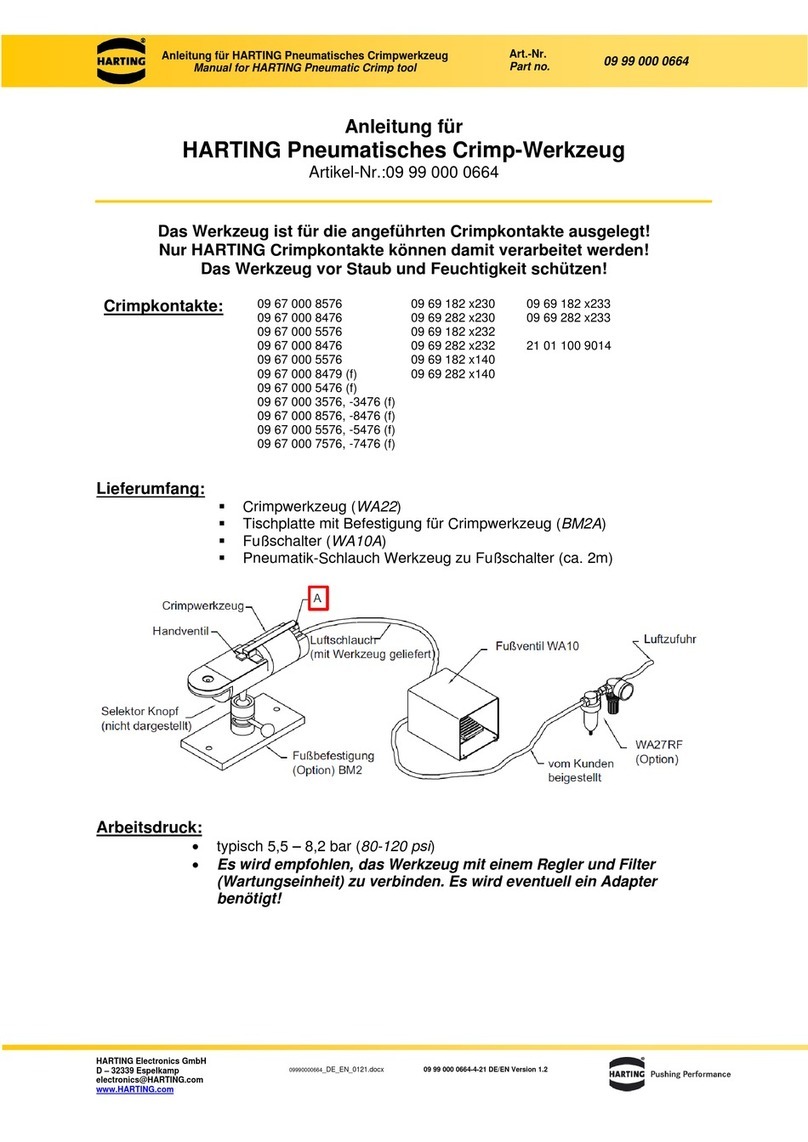

HARTING 09 99 000 0664 User manual

HARTING

HARTING 09 99 000 0001 Instruction manual

HARTING

HARTING 09 99 000 0501 User manual

HARTING

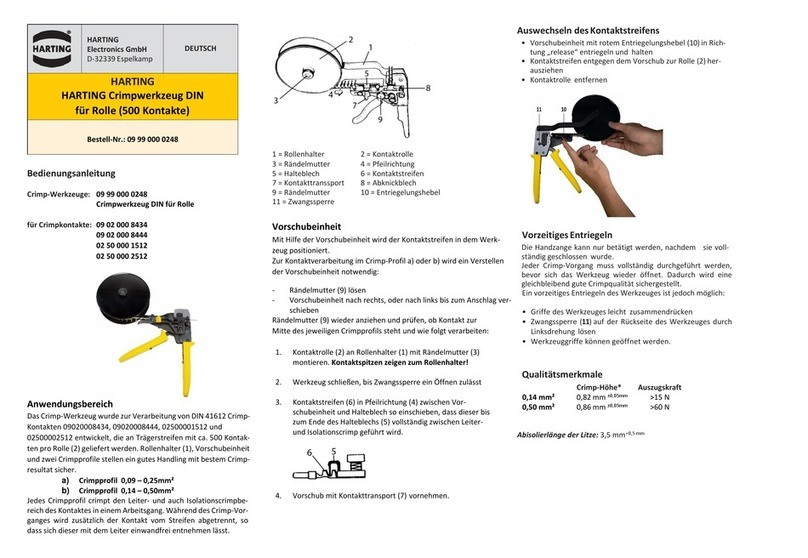

HARTING 09 99 000 0248 User manual

HARTING

HARTING 09 69 82 5140 Series User manual

HARTING

HARTING 09 45 800 2800 User manual

HARTING

HARTING 09 99 000 0119 User manual

HARTING

HARTING 09 99 000 0501 User manual

HARTING

HARTING M17 User manual

HARTING

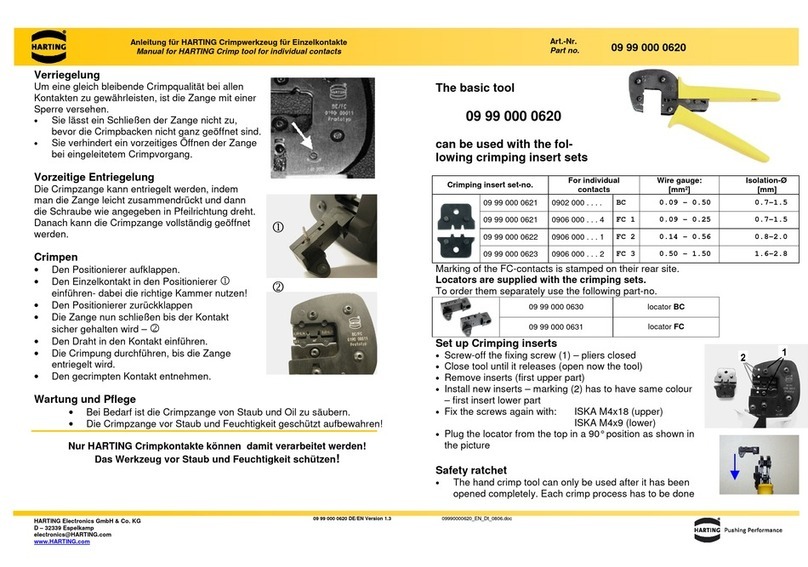

HARTING 09 99 000 0620 User manual

HARTING

HARTING 09 99 000 0647 User manual

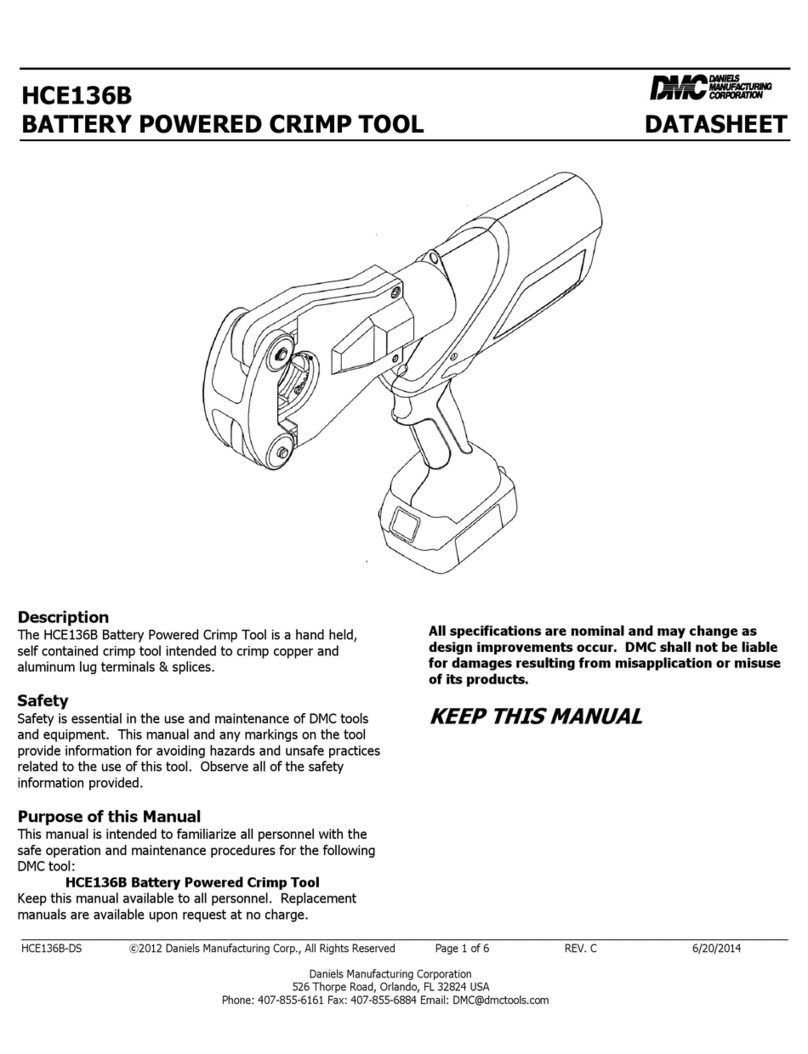

Popular Crimping Tools manuals by other brands

Bollhoff

Bollhoff RIVCLINCH 0201 FS user manual

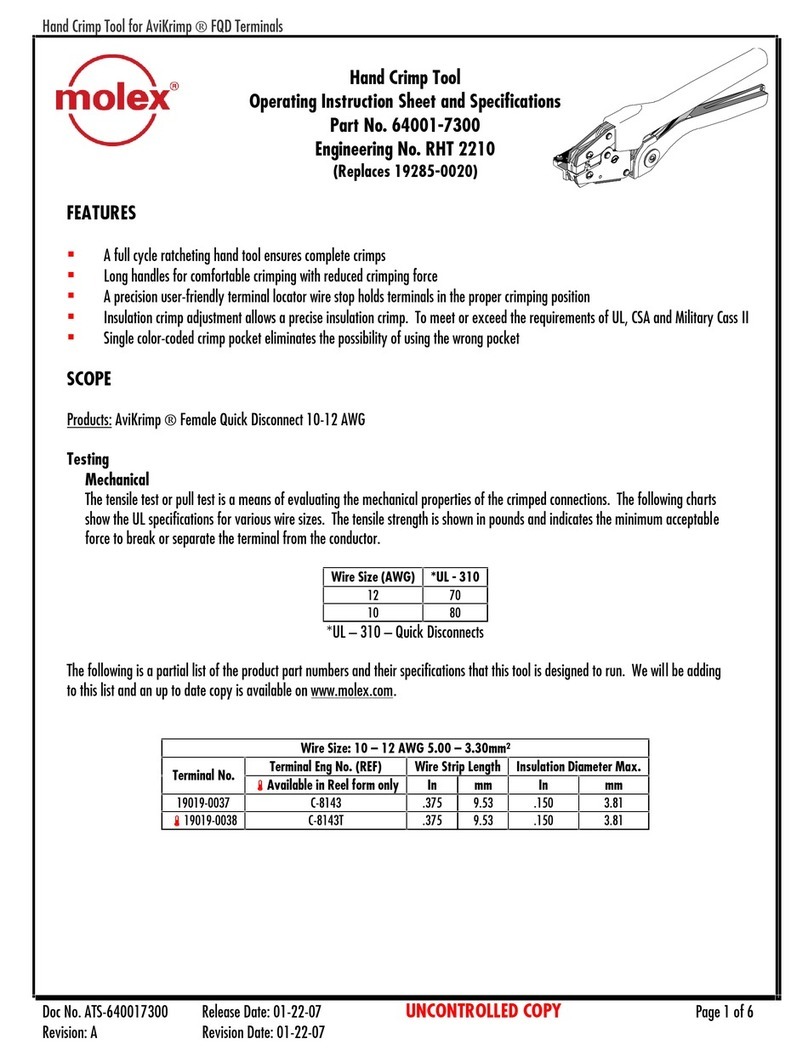

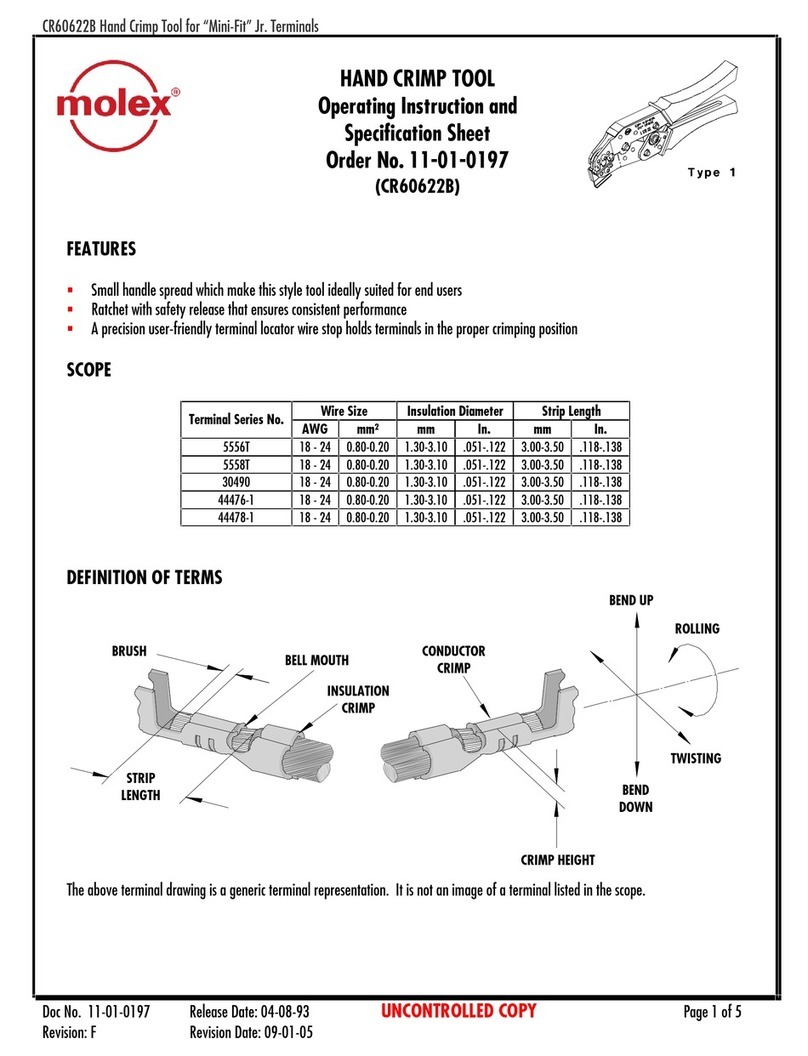

molex

molex 207129 Series Operating Instruction Sheet And Specifications

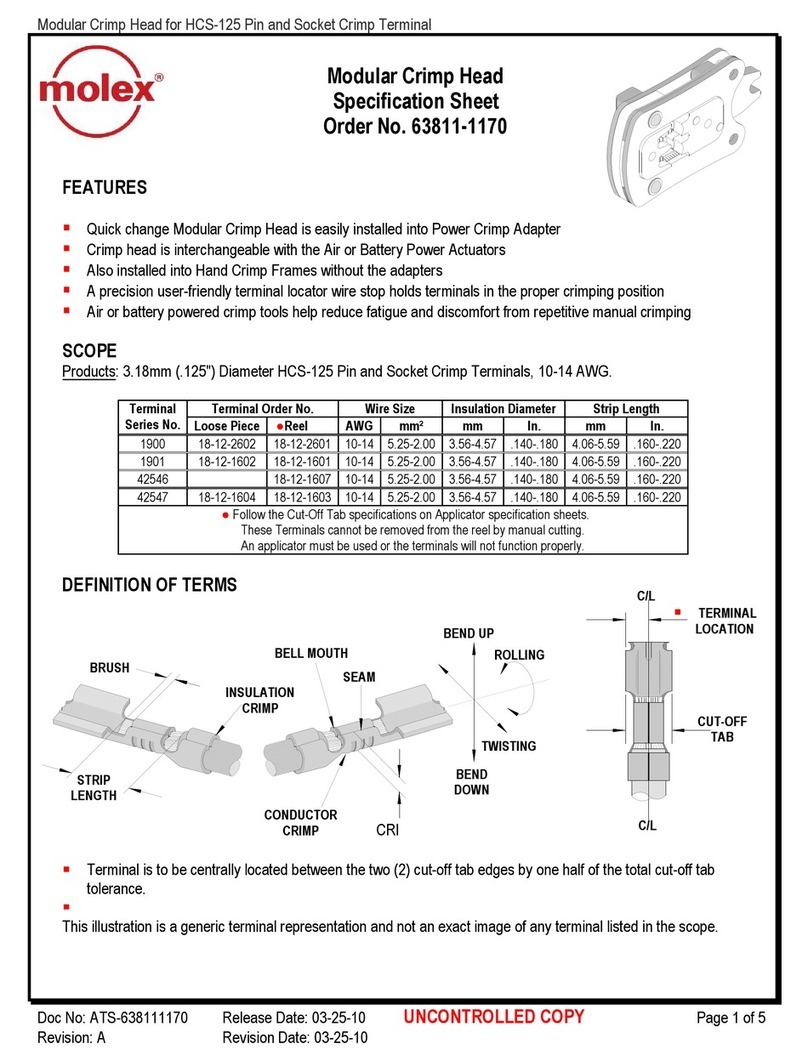

molex

molex HCS-125 Series Specification sheet

Emerson

Emerson Klauke EK 135FTCFM manual

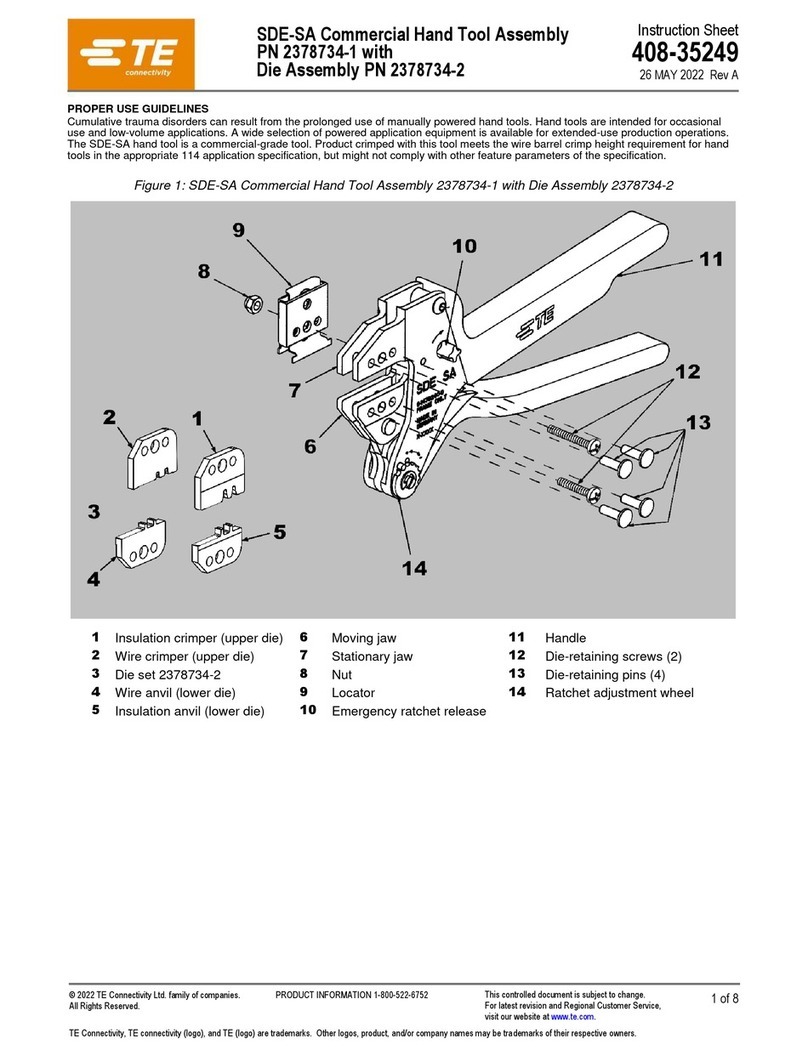

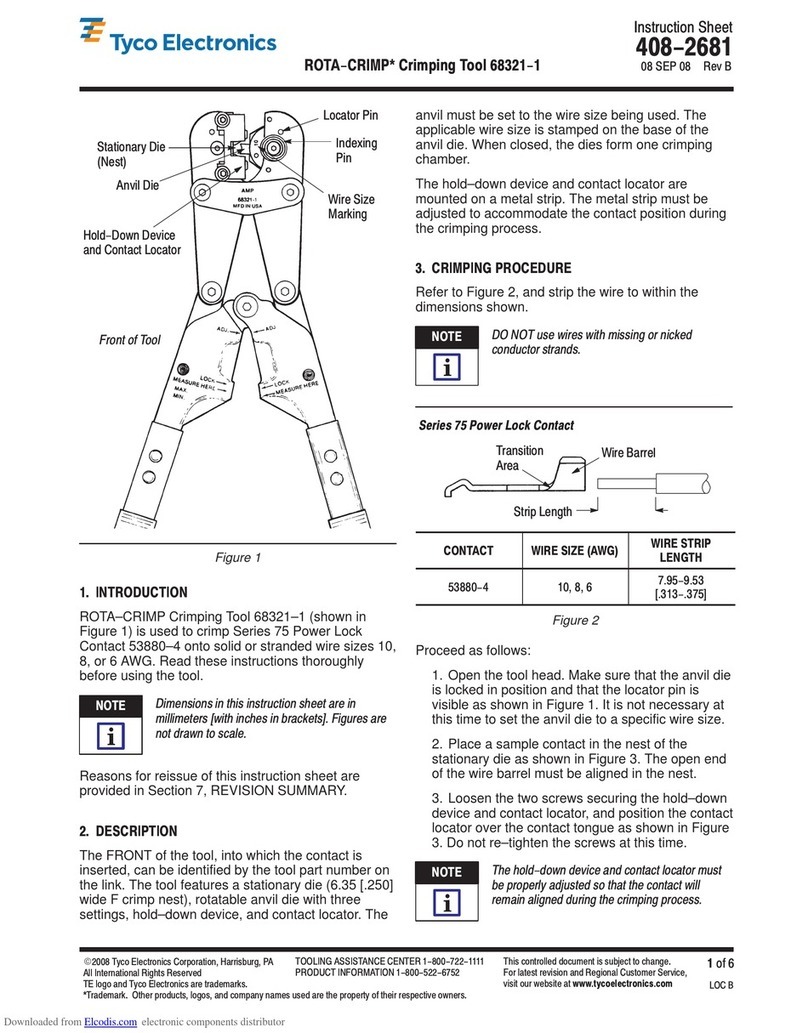

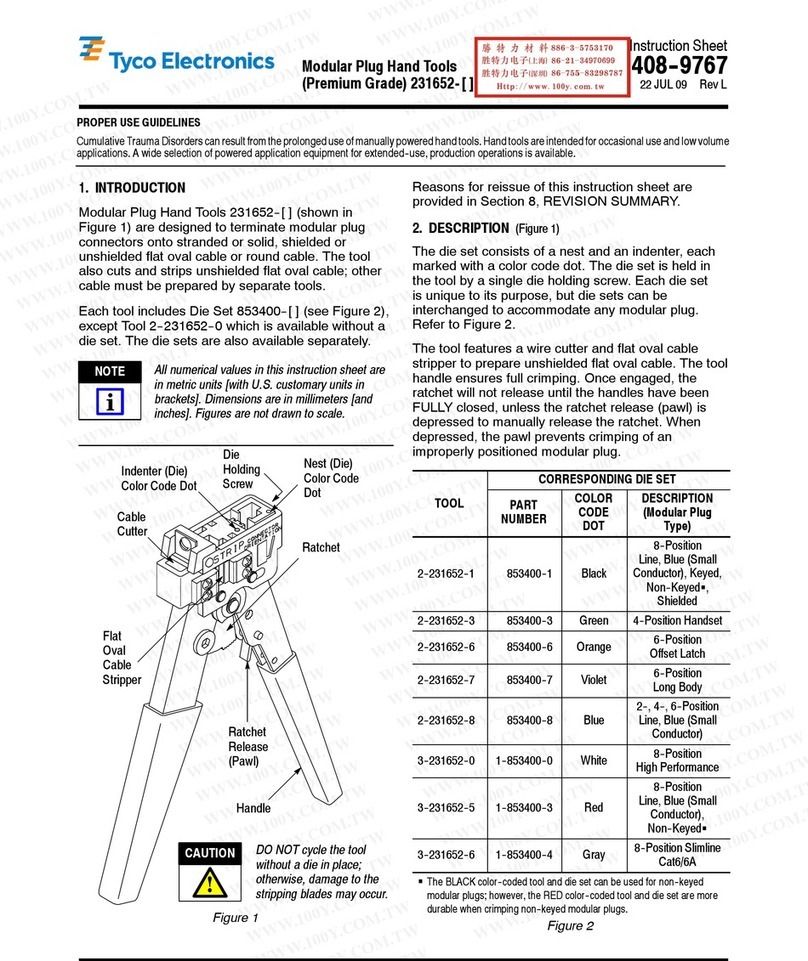

Tyco Electronics

Tyco Electronics ROTA-CRIMP 68321-1 instruction sheet

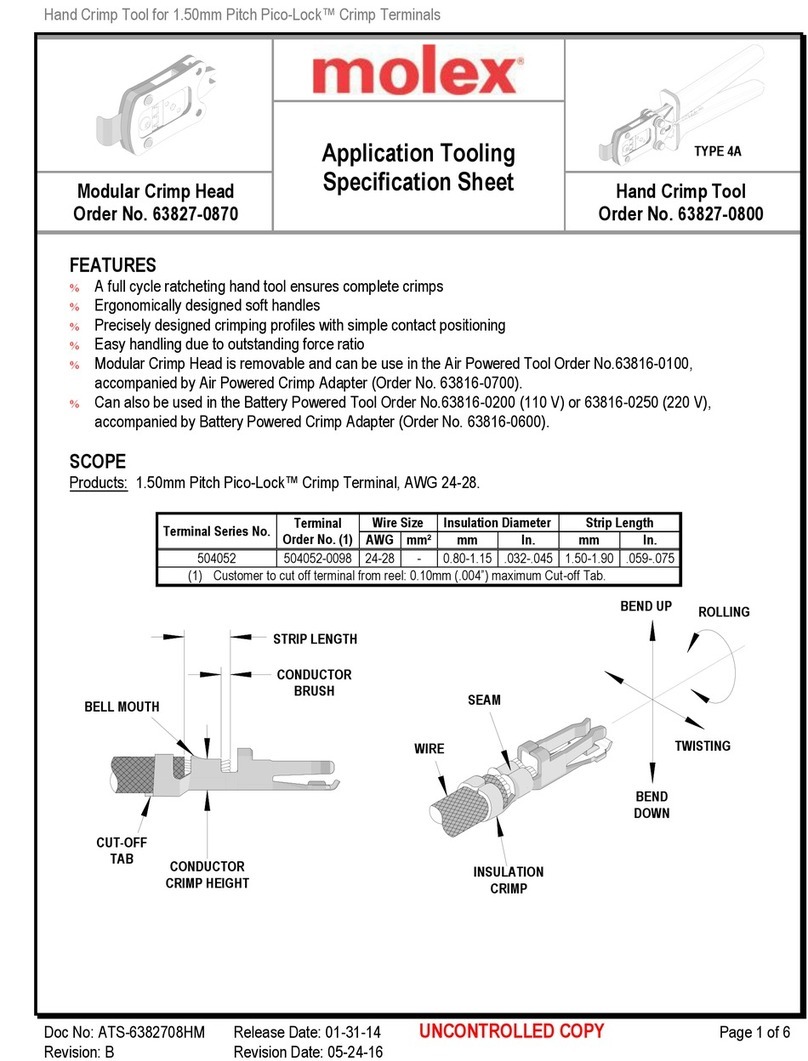

molex

molex 207128 Series Specification sheet

Conec

Conec 36-000530 operating instructions

molex

molex CR60622B Operating Instruction and Specifications Sheet

Cable Bullet

Cable Bullet YYQ-300 instructions

Emerson

Emerson Klauke UAP332CFB manual

Tyco Electronics

Tyco Electronics 2-231652-1 instruction sheet

Tyco Electronics

Tyco Electronics PRO-CRIMPER III instruction sheet