SB01A

6

A1020-4.0 en/de/frHBM

Qualified personnel

This instrument may only be installed and used by qualified personnel, strictly

in accordance with the technical data and the safety requirements and

regulations listed below. It is also essential to comply with the legal and safety

requirements for the application concerned during use. The same applies to

the use of accessories.

Qualified personnel means persons entrusted with the installation, assembly,

commissioning and operation of the product who possess the appropriate

qualifications for their function. Maintenance and repair work at the open, live

device may only be performed by trained personnel who are aware of the

potential danger.

CAUTION

Start‐up and installation are to be implemented only by technical personnel

for this special‐trained.

Installation of the devices outside the potential explosive atmosphere

SThe Zener barriers are constructed to comply with protection class IP20

according to EN 60529 and must be protected accordingly from adverse

environmental conditions such as water spray or dirt exceeding the degree of

soiling 2.

SZener barriers must be installed outside the potential explosive atmosphere!

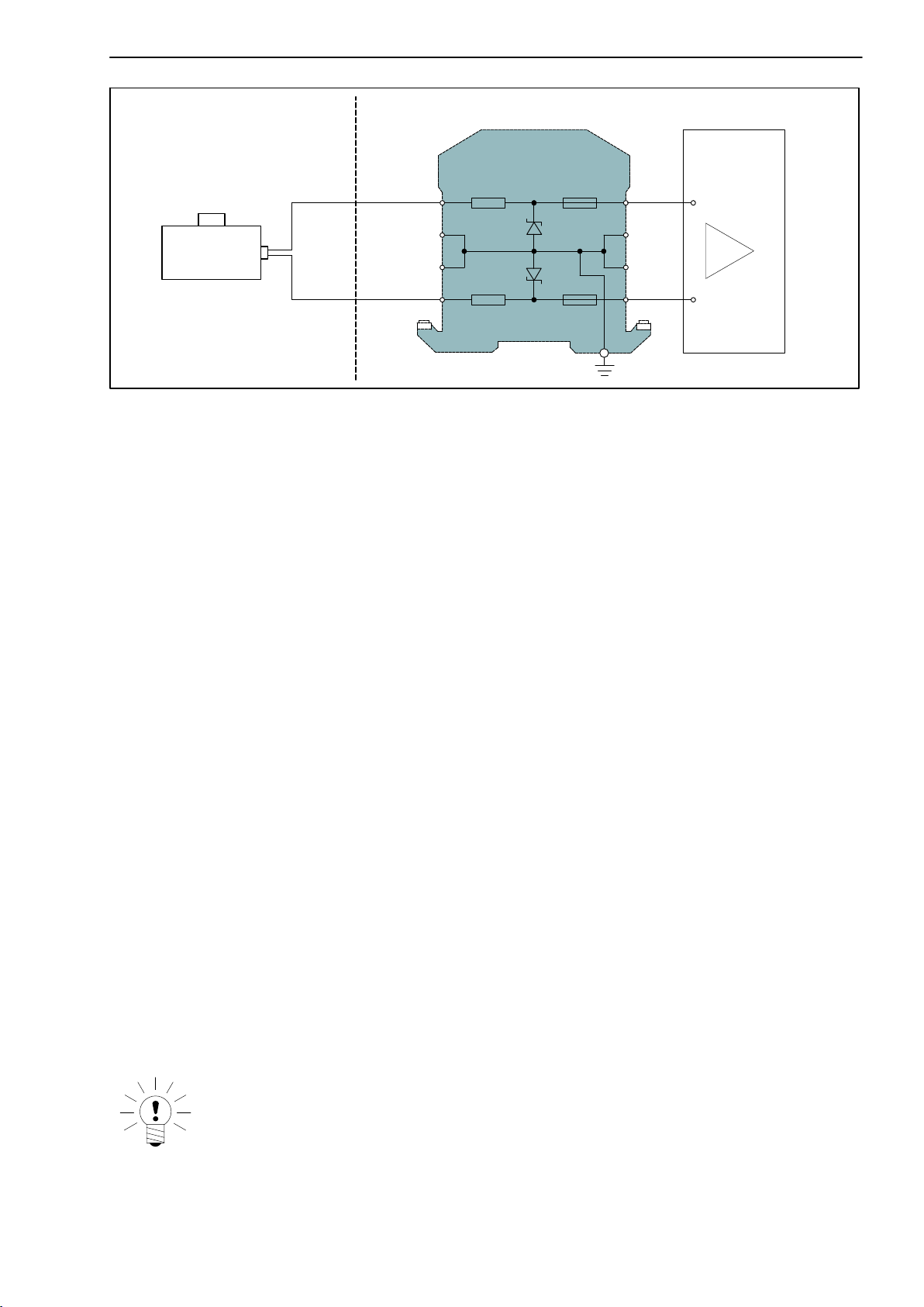

SThe intrinsically safe circuits of the devices (light blue marking at the devices)

can be - depending on the type of protection - conducted through potential

explosive atmospheres. In this connection, it is particularly important to ensure

the safe isolation of all non‐intrinsically safe circuits.

SWhen intrinsically safe field devices (load cells) are interconnected with the

intrinsically safe circuits of the related Zener barriers, the respective maximum

values for the field devices (load cells) and the Zener barriers - in the sense

of explosion protection - must be observed (proof of intrinsic safety).

EN 60079‐14 / IEC 60079‐14 has to be observed. For the Federal Republic of

Germany the national foreword of the DIN EN 60079‐14 / VDE0165 part 1 has

to be observed additionally.

SThe EC Certificates of Conformity or EC‐Type Examination Certificates have

to be observed. It is especially important to observe the ”Special conditions”

where these are contained in the certificates.

SWhen intrinsically safe circuits are used in explosive atmospheres caused by

dust (Ex‐Area 'D') only approved field devices (load cells) must be used.