Unplug the power cord before servicing or replacing filters. Failure

to do so could result in serious personal injury and death.

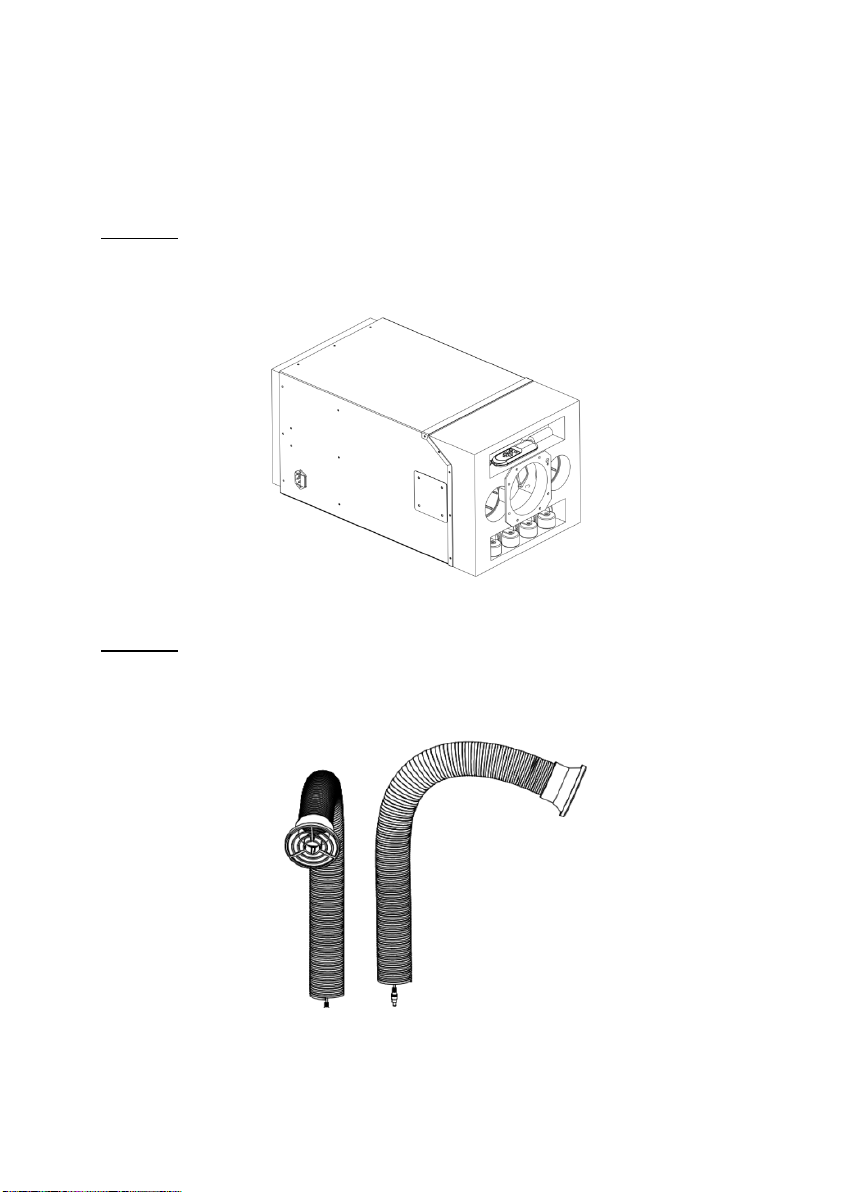

I. Important Safety Instructions

Read the Owner's Manual and Important Safety Instructions carefully. Failure to

follow these instructions could cause a malfunction of the unit.

It is advised that a surge protector device with a minimum rating of 1,000 Joules

is used to protect the HealthyAir®unit from damage by AC power transients or

lightening surges.

To reduce the risk of electric shock, fires, and/or injury:

•Do not use the unit in wet or damp locations

•Do not use outdoors

•Do not use at ambient temperature of above 95°F/35°C

•Do not use fabrics or other material to cover the inlet and outlet of the unit

•Do not allow children to operate or play with the unit

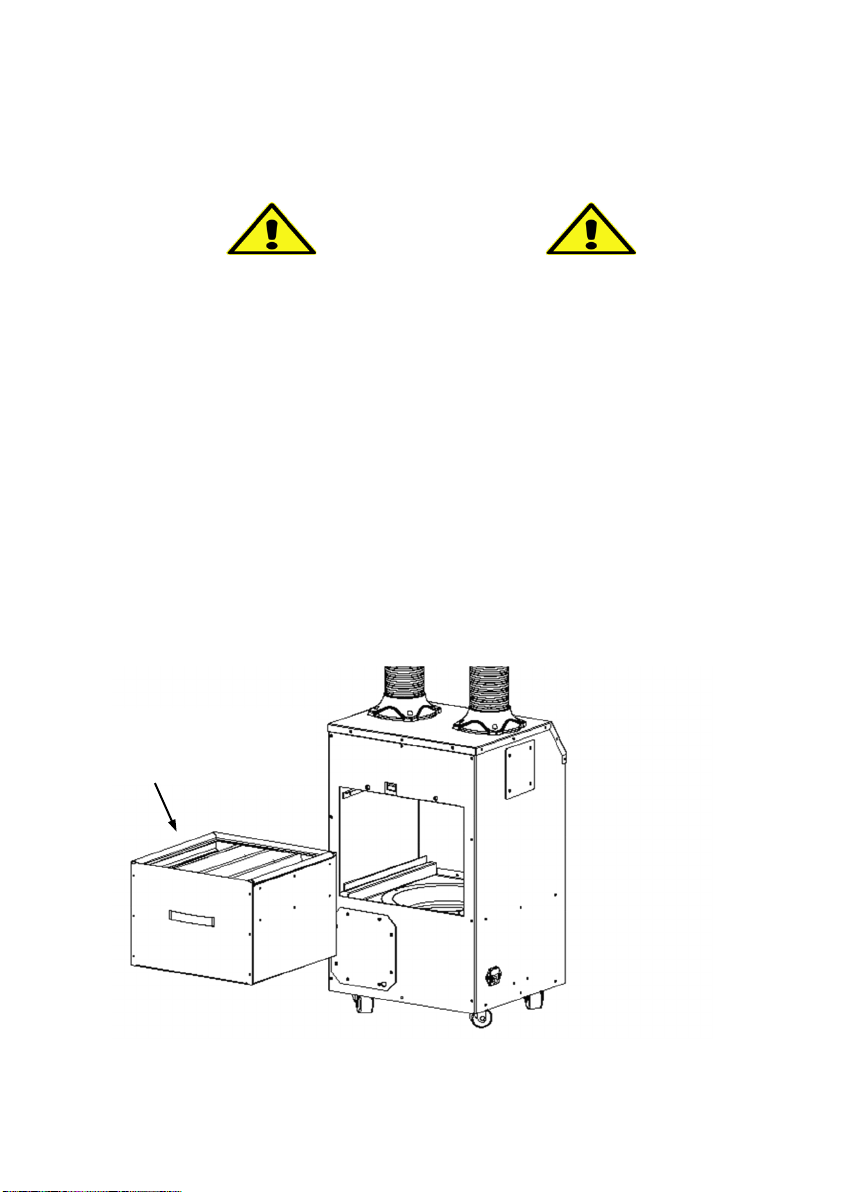

For safety reasons and to prevent electric shock, unplug the power cord from the

electric outlet socket under the following conditions:

•When not in use for a long period of time

•When cleaning, servicing, moving, or replacing filters

To prevent electric shock, do not dismantle, repair or modify this product.

Maintenance and cleaning instructions should be followed exactly as directed in

this manual. In case of malfunction, please contact an authorized distributor or

Healthy Air Inc. for service instructions.

To reduce the risk of electric shock, the equipment has a grounding type plug

that has a third (grounding) pin. This plug will only fit into a grounding type power

outlet. If the plug does not fit into the outlet, contact qualified personnel to install

the proper outlet. Do not alter the plug in any way.

To reduce the risk of electric shock, do not pull the cord to remove the plug from

its outlets. Protect the cord against heat, oil and sharp objects. Do not run any

appliance over the cord. Do not pull or carry by the cord, use cord as a handle,

close a door on the cord, or pull cord around sharp edges or corners.