BMA/BMB-Tool Tool description

Intended use

1. Check the package delivered to ensure that it is not damaged.

Should you identify any damage to the package, then open the package

in the presence of the delivery service and check the BMA/BMB Tool

for hidden damage. Any transport damage to the package supplied and

damage to the BMA/BMB Tool shall e registered in a damage report

y the delivery service.

2. Open the package supplied and check for completeness ased on the

delivery slip.

3. Remove the BMA/BMB Tool from the packaging.

4. Check the BMA/BMB Tool for damage and completeness.

2.2 Intended use

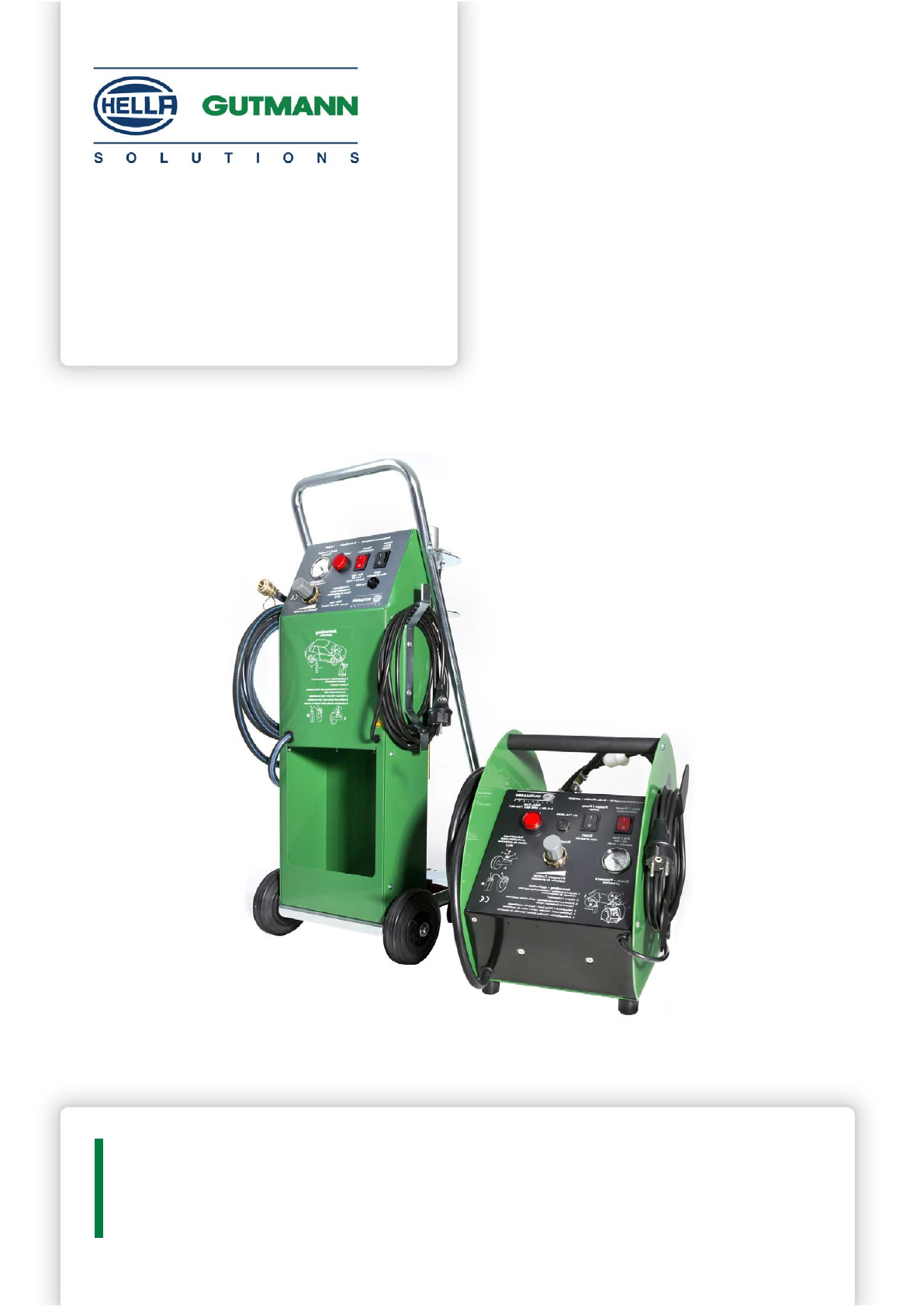

The BMA/BMB Tool (Brake Maintenance A or B model) is a rake

maintenance tool for filling and leeding hydraulic systems containing

rake fluid in motor vehicles, e.g. rake or clutch circuits. The BMA/BMB

Tool may only e used with DOT 3, DOT 4 or DOT 5.1 (glycol- ased) rake

fluid. Hydraulic fluid ased on mineral oil or DOT 5 rake fluid (silicone-

ased) is not suita le for the BMA/BMB Tool and must therefore not e

used. As rake fluid is very hydroscopic (a sor s and retains moisture),

the BMA/BMB Tool must e stored and operated in dry conditions.

For maintenance of the hydraulic system, the BMA/BMB Tool is connected

to the associated rake fluid reservoir using a suita le adapter. A

pressurised electric pump delivers new rake fluid from the BMA Tool or

BMB Tool to the rake fluid reservoir. The supply pressure can e

continuously adjusted from 0 to 2.8 ar. The rake fluid current pulsates

during the leeding phase of the hydraulic system. These fluctuations

ena le a complete leeding process, as even the smallest amounts of air

or moisture at the pipe connections are carried away.

After switching off the electric pump, the pressure in the rake fluid

reservoir reduces and the correct rake fluid level is automatically set.

If the rake fluid container is emptied to the minimum filling level, the

pump switches off automatically. This ensures that air never gets into the

hydraulic system.

9