3

K0320 Issue No. 1

Millivolts ................................................. 52

Volts........................................................ 54

Milliamps/XMTR .................................. 54

Ohms ...................................................... 56

Frequency .............................................. 56

Pulse Counter Mode ............................. 58

Switch position change......................... 60

Circuit continuity tester......................... 62

To measure a thermocouple

Using compensation wires ................... 64

Using the standard test leads

(copper wires)........................................ 66

To measure a RTD

With the remote probe (optional)......... 68

Special Measurement Functions

Scaled readings..................................... 70

Setting up scaled readings (linear

relationship) ....................................... 70

Setting up scaled readings

(flow relationship) .............................. 72

Output of electrical signals

General................................................... 74

Set mode ............................................ 74

Output mode....................................... 76

Changing the output level ................. 76

Millivolts ................................................. 78

Volts........................................................ 80

Milliamps/XMTR .................................... 80

Ohms ...................................................... 82

Frequency .............................................. 82

Counter................................................... 84

To simulate a thermocouple

RTD Simulation

Excitation current .................................. 88

Special Output Functions

Step Mode .............................................. 92

Ramp Mode............................................ 94

Setting up the ramp mode ................ 94

To start/stop a ‘one shot’ ramp ........ 96

To start/stop ramp cycling ................ 96

Scaled readings..................................... 96

User Power supplies

Transmitter calibration

Setting up a calibration ....................... 100

To check or calibrate a transmitter ... 102

Temperature transmitter simulation

Setting up a simulation ....................... 104

To simulate a transmitter.................... 106

Programmable signal converter

Setting up a signal converter ............. 108

Ce Remarks

Ce Remarks ......................................... 110

Service, Repair and Parts

Recalibration of the MCX-II ................ 112

Cold juntion compensation

calibration ......................................... 114

Lithium cell replacement..................... 118

Fault finding procedures ..................... 120

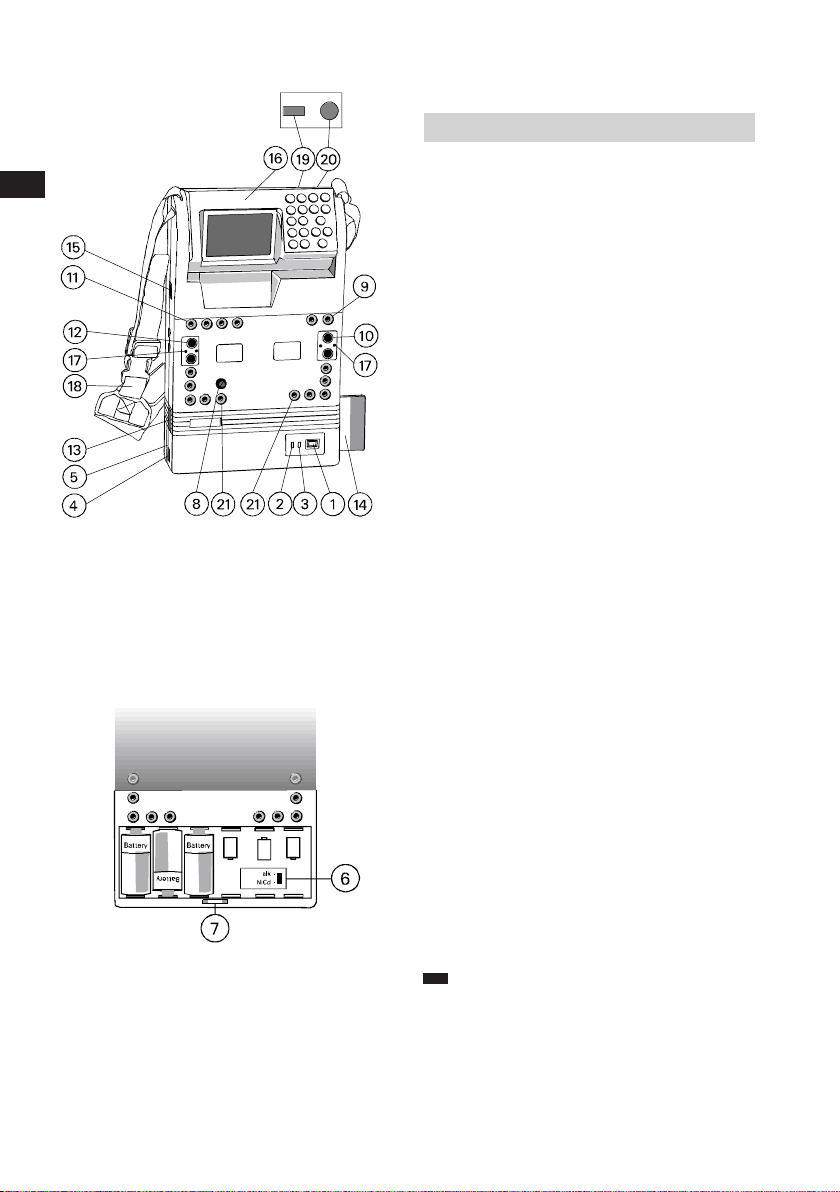

Opening and closing the calibrator

housing ............................................. 120

Fault finding procedures ..................... 122

Spare parts list................................. 128

Specifications

Protocol for RS232 System Integration

.......................................................... 142

Warranty & Liability