CheckingandsettingheadlampsNationalregulationsmustbeobserved)

Settingup

5CheckingandsettingheadlampsNationalregulations

mustbeobserved)

NOTE

Theheadlightaimingdevicecanbeusedtoinspectallheadlightsystems,includingDE,FF,LED

andXENONheadlights.Therectangledrawnonthetestscreencorrespondstothesizeofthetest

surfacewhichismandatoryundertheDirectivefortheadjustmentofvehicleheadlamps.After

headlampshavebeenadjusted,theymustbefastenedonthevehicleinsuchawaythatitisnot

possibleforthemtobeaccidentallymovedoutofalignment.Headlampsettingsshouldbechecked

wheneverrepairshavebeencarriedouttoavehicle’ssuspension.Thisisalsorecommended

wheneveraheadlampbulbhasbeenreplaced.

Ifthevehicleisfittedwithanautomaticmechanismtocompensateformovementsinthebodyworkorheadlamps

causedbychangesintheload,thecharacteristicsofthismechanismasdescribedinthemanufacturer’sinstructions

mustbetakenintoaccount.

Tosettheheadlamps,iftheycanbeadjustedbyhandonthisparticularvehicle,theadjustmentmechanismmustbe

intheexactprescribedpositionforthebasicsetting.

Iftheadjustmentmechanismonlyprovidesfortwopositionsfortheheadlamps,andtheexactpositionisnotspecially

marked,theprocedureisasfollows:

•Ifthelightbeamrisesasthevehicle’sloadisincreased,thesettingmustbecarriedoutwiththeadjustment

mechanisminitsendpositionandthelightbeaminitshighestposition.

•Ifthelightbeamfallsasthevehicle’sloadisincreased,thesettingmustbecarriedoutwiththeadjustment

mechanisminitsendpositionandthelightbeaminitslowestposition.

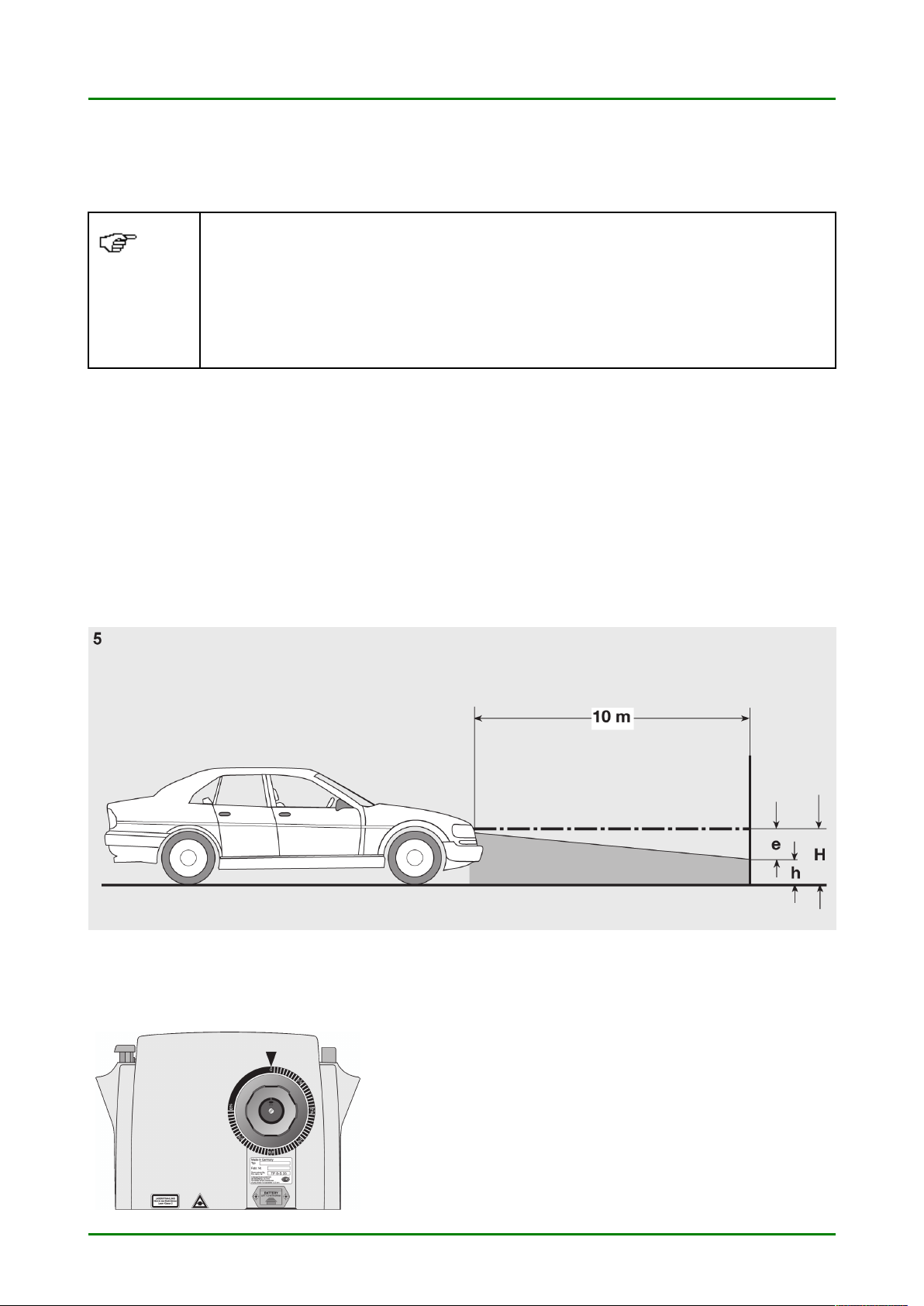

e=Distanceincmbywhichthecut-offlinemustbeinclinedatadistanceof10metres

H=Heightofthecentreoftheheadlampabovethefloor,incm

h=Heightofthedividinglineofthetestareaabovethefloor,incm.

Scaledwheel

Variousdifferentanglesofinclinationofthecut-offlineexpressedin

%areprescribedforthevarioustypesofvehilcleseeadjustment

table—cut-offlinein%x10correspondstodimension“e”)

10