Installation instructions and Instructions for use

Subject to technical modifications – Date of Issue

November/2022

5

CE marking

The top-mounted box TOP MINI plus with roller shutter from HELLA has a declaration of

performance as per the Construction Products Regulation and when equipped with a motor

drive, it also has the declaration of conformity as per the Machinery Directive or the

Directive for Electromagnetic Compatibility and meets the basic requirements of the

harmonised standard EN 13561 if used as intended. The respective declarations are

deposited with the manufacturers.

* ... Established wind resistance classes of the installed roller shutter profiles with the

corresponding guide rails - see chapter "Intended use".

The CE identification applies for the delivery status of the product. The product mounted

meets the requirements of the specified standard only, if

during installation the information and instructions given in these instructions as well

as the information and instructions of the manufacturers of the screws have been

observed,

the product is installed with the recommended type and number of fasteners/screws.

No changes, rebuildings or extensions, with the exception of those described in these

instructions, are allowed with this product. The fixed CE-label expires with any change,

rebuilding or extension.

HELLA Sonnen- und Wetterschutztechnik GmbH

A-9913 Abfaltersbach, Nr. 125

16

LE-AKRO-01-002

EN 13659:2004+A1:2008

Top-mounted box with roller shutter

TOP MINI plus

Exterior sun protection

Wind resistance class 0-6*

Installation instructions and Instructions for use

6

Subject to technical modifications – Date of Issue

November/2022

CE marking

The HELLA insect screen – moscita, an insect roller screen that is integrated in the

box/recess, is in compliance with the declaration of performance according to the

Construction Products Regulation. In case of proper use, it corresponds to the basic

requirements of the harmonised standard EN 13561. The respective declaration is

deposited with the manufacturer.

The CE identification applies for the delivery status of the product. The product mounted

meets the requirements of the specified standard only, if

during installation the information and instructions given in these instructions as well

as the information and instructions of the manufacturers of the screws have been

observed,

the product is installed with the recommended type and number of fasteners/screws.

No changes, rebuildings or extensions, with the exception of those described in these

instructions, are allowed with this product. The fixed CE-label expires with any change,

rebuilding or extension.

HELLA Sonnen- und Wetterschutztechnik GmbH

A-9913 Abfaltersbach 125

16

LE-ISRO-01-001

EN 13561:2004+A1:2008

Insect roller screen

moscita

Exterior insect screen

Wind resistance class 0

Installation instructions and Instructions for use

Subject to technical modifications – Date of Issue

November/2022

7

Safety instructions

These installation instructions refer to prefabricated elements, that (1) for

100% are made from parts, which are defined by us, and (2) which are

made in manufacturing processes, which are defined by us too; in all other

cases we do not provide any guarantee!

The safety instructions as well as the appropriate instructions must be read

carefully before installation and use. In case of non-observance of the

directions and information given in these instructions and in case of

improper installation and operation or unintended use, the manufacturer

shall not accept any warranty claims concerning any damage to the

product. In these cases, the liability for consequential damage to any parts

or persons is ruled out as well.

- Follow the described installation steps and pay attention to

recommendations and notes.

- Keep these instructions in a safe place.

- All installation and removal works, as well as maintenance and repair

works are only allowed to be carried out by authorised and qualified

specialist staff.

- If switching, automatic or radio control devices are used to operate the

units, the information given in the enclosed instructions of the

manufacturer must be observed.

- During operation do not put your hand into or touch movable parts.

- Ensure that clothing or body parts cannot get caught on the unit.

- Observe the regulations for prevention of accidents of the employer's

liability insurance association!

- Before operation check the unit for visible damage. If the unit is

damaged, it should not be used; please consult authorized specialist

staff immediately.

- Risk of injury and accident due to the weight of the product!

- Take safety measures against the danger of squashing, especially when

operating the unit with automatic devices.

- Place the operating switch within sight of the unit, but not near any of the

moving parts.

- Never let children play with the unit.

A sun protection device with electric drive cannot be retracted without

current. We therefore recommend the use of an emergency power

generating unit or a motor with an emergency crank handle, especially in

regions with frequent power failures.

If the curtain of the selected element has more than 20 kg, an additional

fixing device has to be provided for the box.

Installation instructions and Instructions for use

8

Subject to technical modifications – Date of Issue

November/2022

Safety instructions

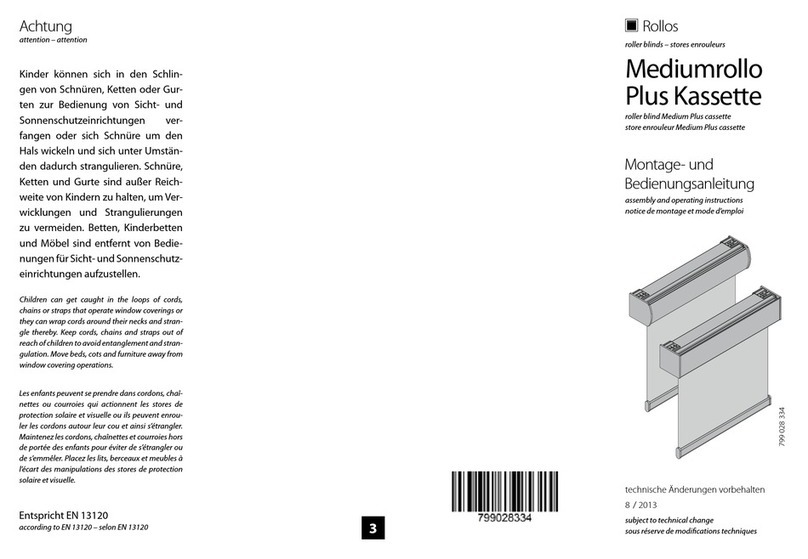

Danger of suffocation!

Ensure that the foil cannot get into the hands of children. Keep the foil in a

safe place.

ATTENTION!

For children / adults a lowered roller shutter is

no protection against a fall out of the window!

Attention! Risk of injury or danger to life due to an electric shock!

- Set-up, examination, commissioning and error correction of the unit must

only be performed by authorised or trained expert staff (as per VDE

0100).

- Switch off the current to the connecting lines when working at the unit.

There is danger to life! Take safety precautions against unintentional

switching on!

- Check the electrical wires regularly for damage. Do not use the unit if

any damage is found.

- Our electrically driven units are in accordance with the regulations for

power plants acc. to VDE 0100. We cannot guarantee for the operational

reliability of the unit with non-approved modifications.

- White motor cables are not UV-resistant and must therefore be routed in

empty conduits, cable ducts, or similar.

- The enclosed installation instructions of the electrical devices supplied

must be observed.

Units with motor drive:

The drives used are operated with a voltage of AC 230V/50Hz. Please

check the power supply provided by your utility company before connecting.

Any other voltage can destroy the drives.

Units with crank handle drive:

Fold the crank handle only into the specified direction. Operate the unit

steadily, avoid using force.

Do not continue to raise or lower the roller shutter curtain, when the limit

stop is reached. The limit stops protect your units.

Units with crank handle drive and lift tape:

Fold the crank handle only into the specified direction. Operate the unit

steadily, avoid using force.

Do not continue to raise or lower the roller shutter curtain, when the limit

stop is reached. The limit stops protect your units.