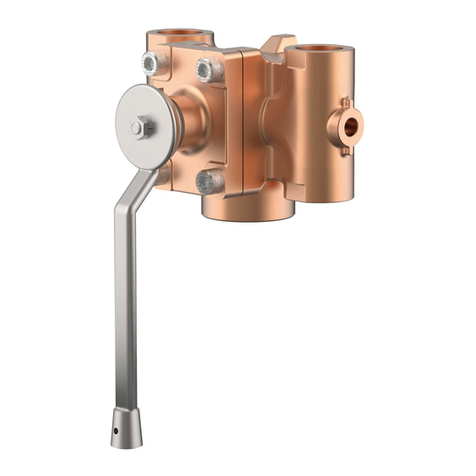

HEROSE 06602 User manual

This manual suits for next models

16

Table of contents

Other HEROSE Control Unit manuals

HEROSE

HEROSE 06001 User manual

HEROSE

HEROSE 0131 Series User manual

HEROSE

HEROSE 0651X User manual

HEROSE

HEROSE 06810 User manual

HEROSE

HEROSE 7111 User manual

HEROSE

HEROSE 01420 User manual

HEROSE

HEROSE 093 Series User manual

HEROSE

HEROSE 0681 Series User manual

HEROSE

HEROSE 0651 Series User manual

HEROSE

HEROSE 0327 Series User manual

HEROSE

HEROSE 0651 Series User manual

HEROSE

HEROSE 06001 User manual

HEROSE

HEROSE 0681 Series User manual

HEROSE

HEROSE 7111 User manual

HEROSE

HEROSE 08411 User manual

HEROSE

HEROSE 03021 User manual

HEROSE

HEROSE 01312 User manual

HEROSE

HEROSE T118 User manual

HEROSE

HEROSE 7111 User manual

HEROSE

HEROSE 01312 User manual

Popular Control Unit manuals by other brands

Keofitt

Keofitt SESAME series user manual

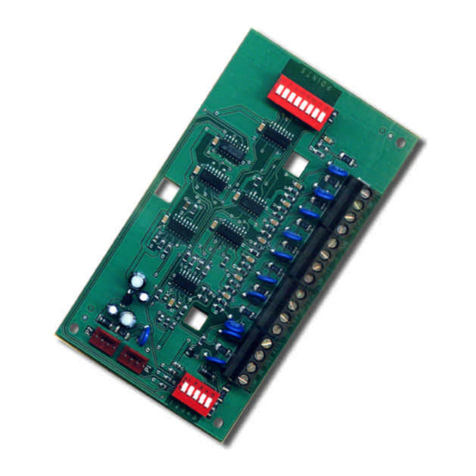

ICP DAS USA

ICP DAS USA MDC-700 Series user manual

Lutron Electronics

Lutron Electronics Grafik Eye GRX-4000 Series Installation, operation and maintenance manual

Xylem

Xylem sensus HRI-Mei FS installation manual

Radionics

Radionics D8128D installation instructions

Dungs

Dungs VPM-VC instructions

VAT

VAT 653 Series Installation, operating, & maintenance instructions

ANTUMBRA

ANTUMBRA DIST Building instructions

Walther Systemtechnik

Walther Systemtechnik WDV-01 Assembly & instruction manual

bonitron

bonitron M3345D Customer Reference Manual

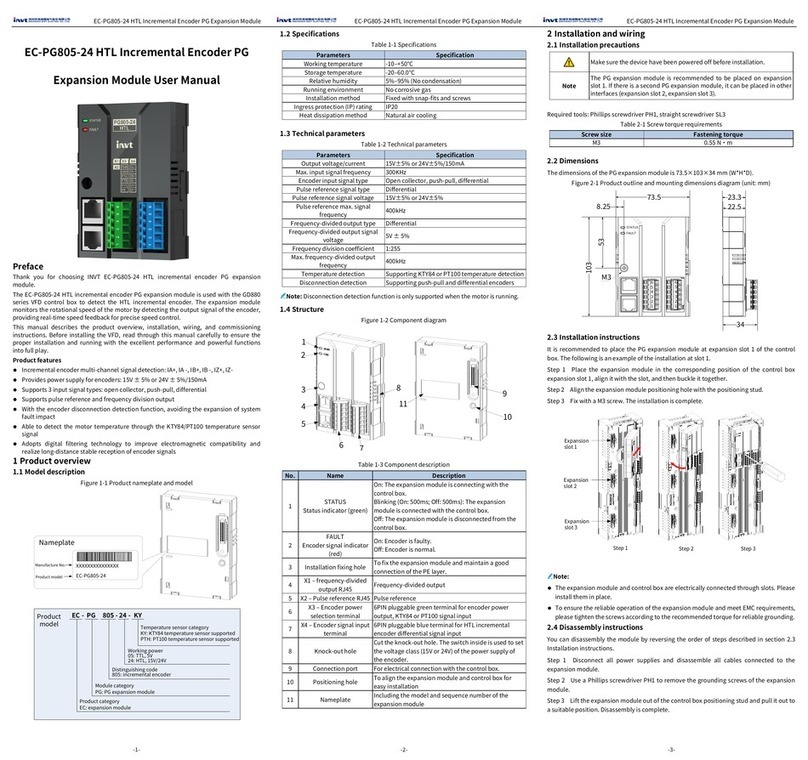

INVT

INVT EC-PG805-24 user manual

Tektronix

Tektronix VX4286 user manual