PAGE 2 OF 3 0812 IH-3518

OPERATING INSTRUCTIONS

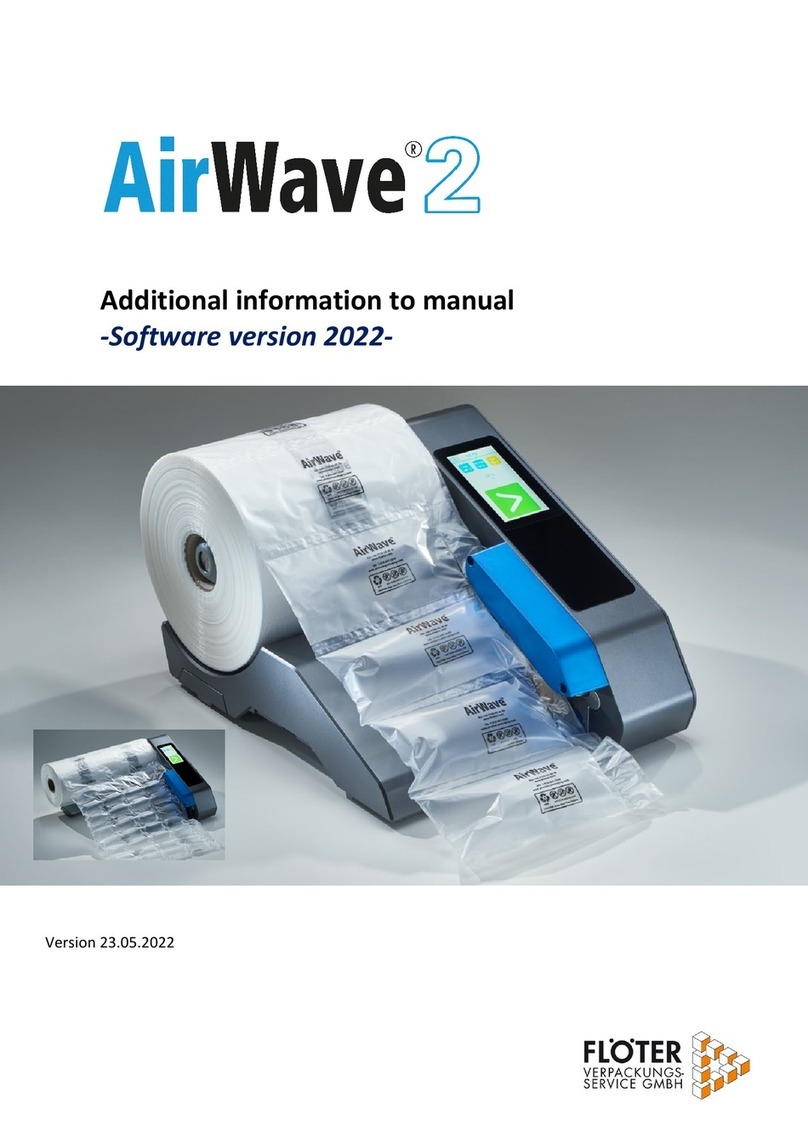

LOADING THE FILM

1. Place machine on a level, stable surface, leaving

sufficient clearance from the floor to prevent the

cushions backing up into the machine.

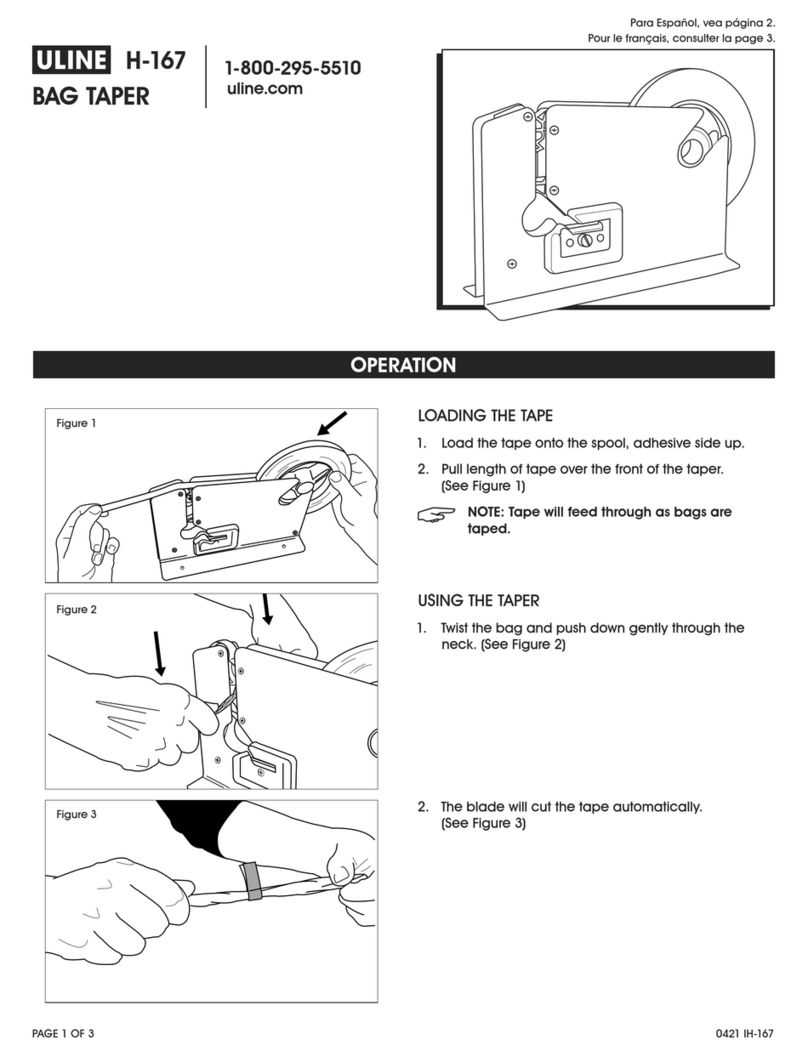

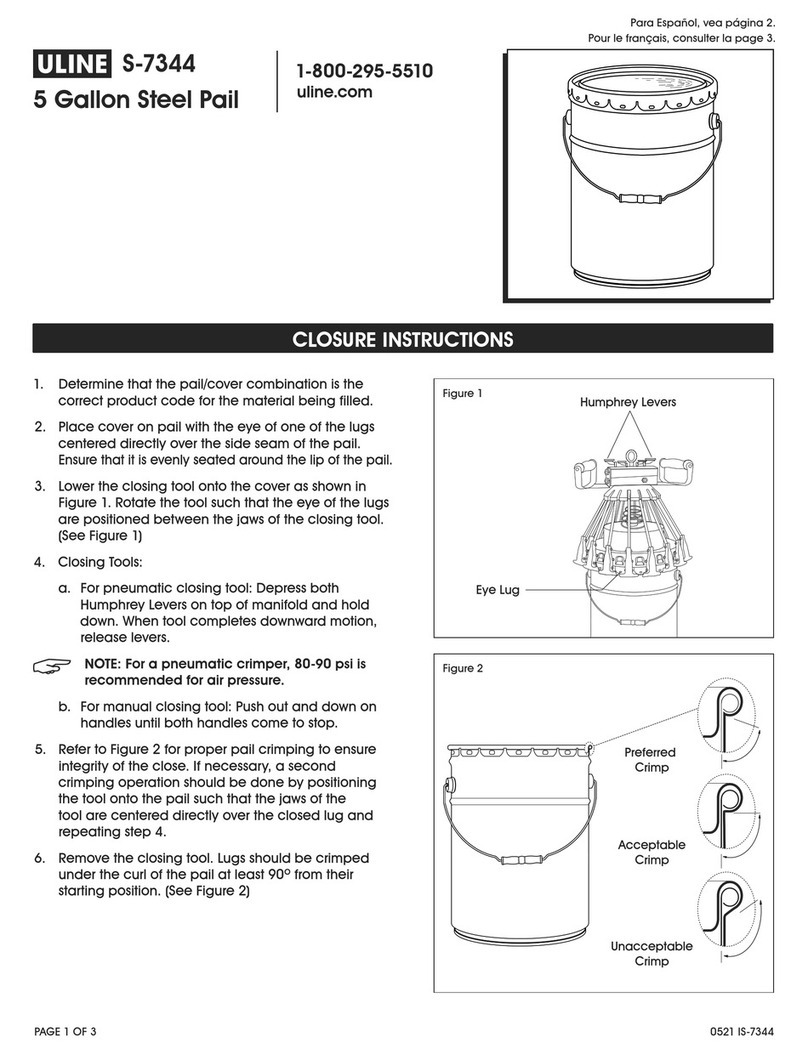

2. Slide the roll onto the axle (A). Ensure that the open

end of the film is closest to the machine. (See Figure 1)

3. Take the film and loop it back over the top roller (B).

4. Open the heat seal mechanism by lifting black

handle (C).

5. Thread the open end of the film onto the guide bar

and pull through the open heat seal mechanism

and through the rubber drive wheel mechanism (D).

NOTE: Ensure that the perforation is NOT on the

drive wheel.

6. The film is now ready to run.

SETTING THE MACHINE SETTING PARAMETERS

(ENGINEERING SETTINGS)

1. Factory default settings are normally ideal for

operation. If machine is not sealing, inflating

or counting properly, settings may need to be

changed.

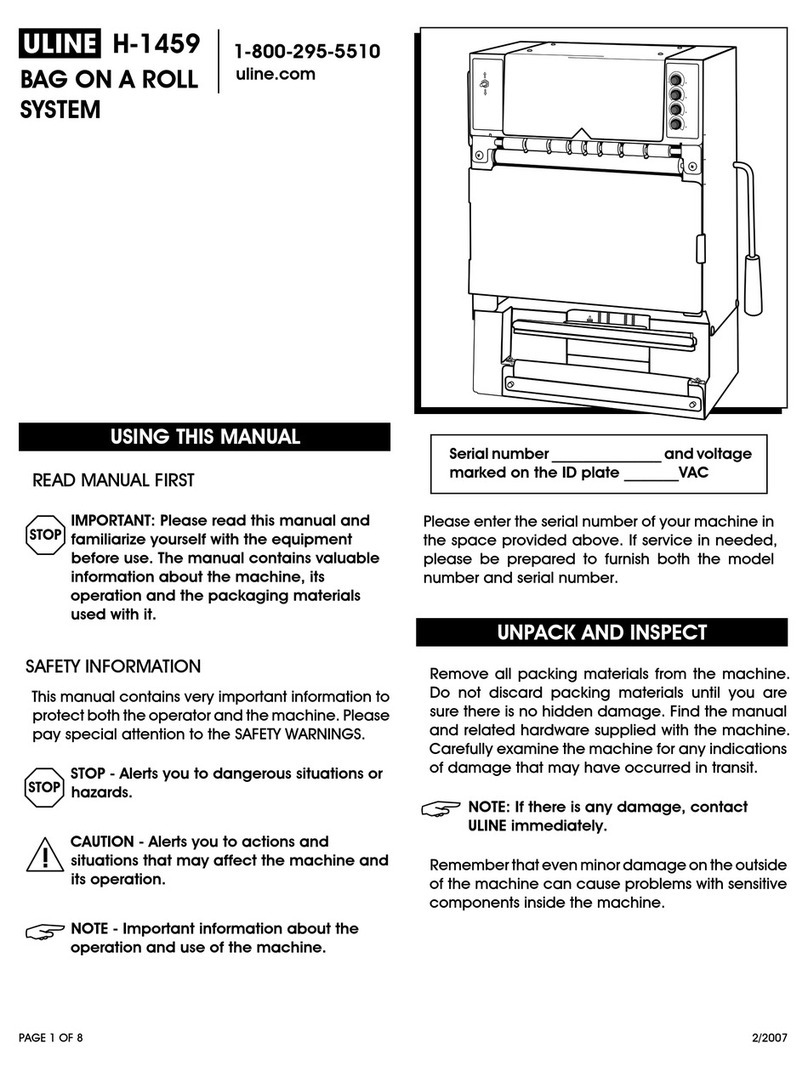

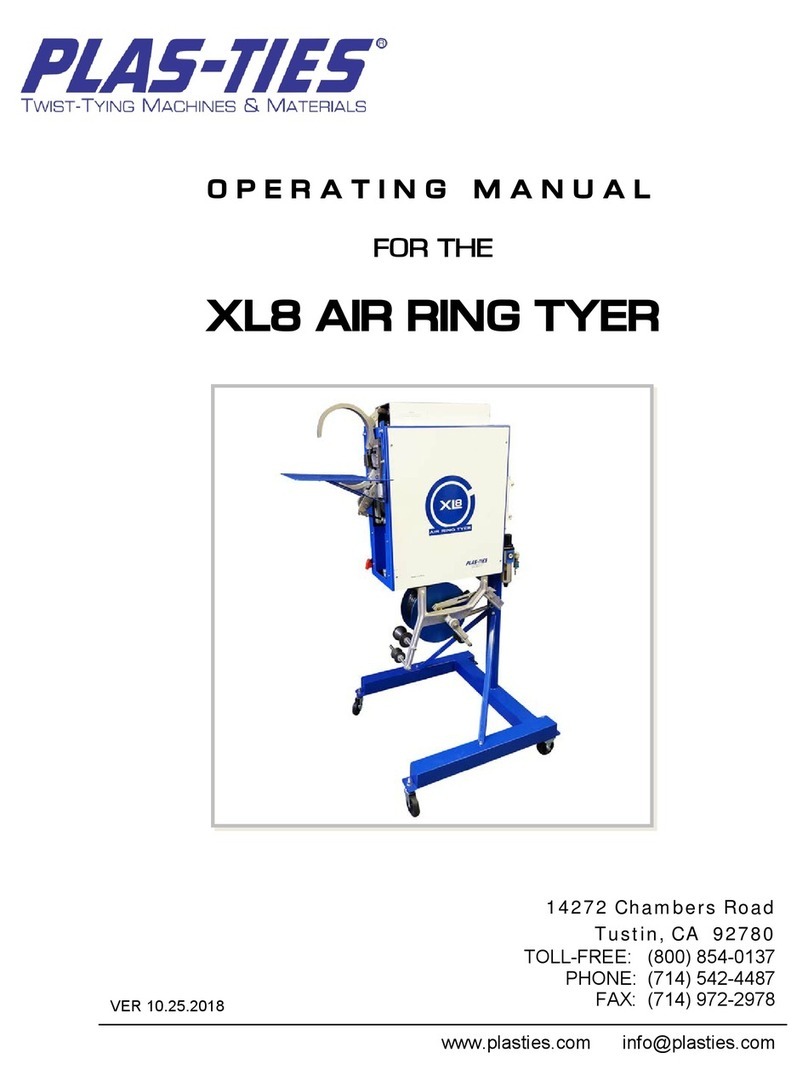

2. In order to change the

default settings, the

following password needs

to be keyed into the display

panel using the arrow keys:

DDUUUDUD (See Figure 2)

3. Using the Select button scroll through the

parameters on the menu that need to be changed.

NOTE: The only parameters that should be

changed are Heat Seal, Blower and Bag Count

settings.

4. Up or down arrows adjust the value of parameters

as required. To change heat seal settings, it is best

to increase or decrease in increments of 10.

5. Once the required parameters have been set, scroll

through the parameters until 'Exit Engineer Mode' is

displayed. Press the 'UP' key.

ADJUSTING THE OPERATOR SETTINGS

Without entering Engineer Mode, the operator can

adjust the following parameters to give the exact

cushion functionality required:

1. Heat seal setting +/- 10

2. Blower speed +/- 10

3. Number of cushions 1 to 10,000

ADJUSTING THE HEAT SEAL AND BLOWER SETTINGS

The operator is able to adjust these settings up 10 units

and down 10 units using the following procedure:

1. Press Select to scroll through the menu options until

you get to the parameter that is to be changed

2. Press the UP/DOWN buttons to change the value

ADJUSTING THE NUMBER OF CUSHIONS

The Uline Green Machine can be run in manual mode

or automatic. In manual, the operator presses the Start

button to begin producing air cushions and the Stop

button to finish the production. The Uline Green Machine

will default to produce 10,000 cushions unless instructed

to do otherwise using the automatic operation mode.

To automatically select the number of cushions required,

press the Select button and scroll through the menu

until you see the Select Number of Bags. Press the UP/

DOWN buttons to adjust to the number you require, up

to 10,000 cushions.

The machine will stop when the count quantity as been

reached.

D

C

B

A

Figure 1

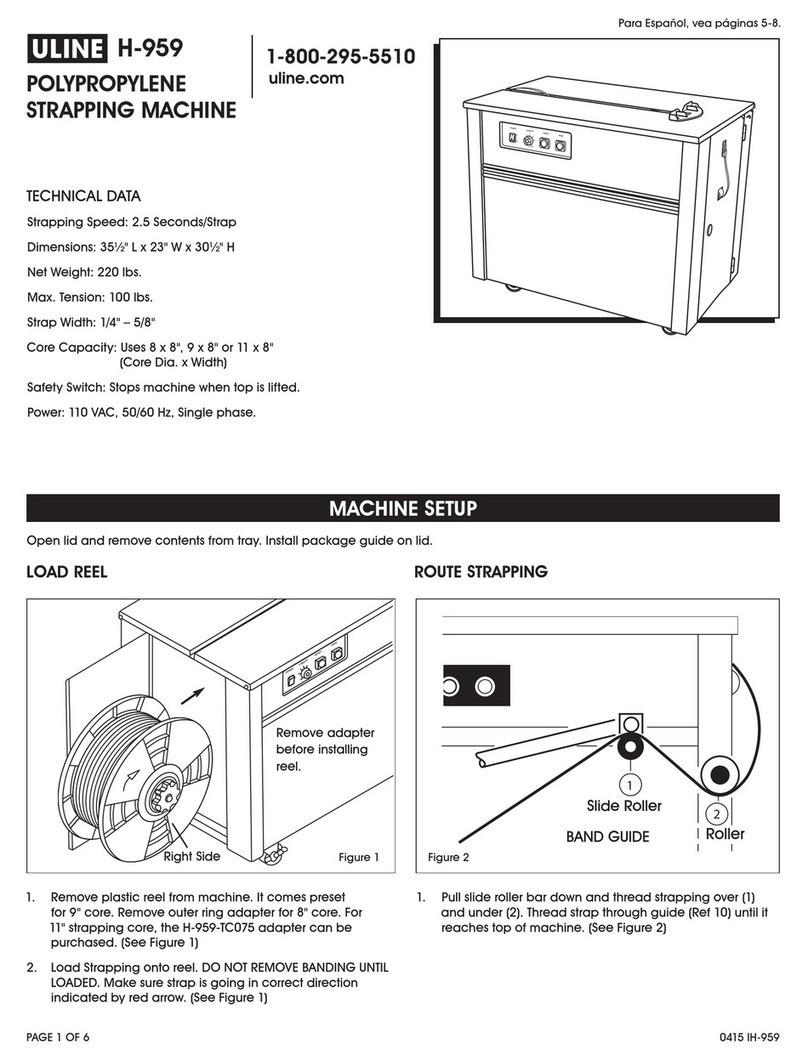

SELECTRESET

START

STOP

Figure 2